Not for

Reproduction

21

• Less spring pre-load should be used with light weight

operators, which will provide a softer, more cushioned

ride.

• More spring pre-load should be used with heavy weight

operator's , which will provide a stiffer, more rigid ride.

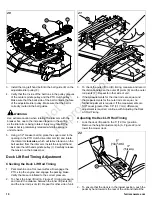

• There are three positions in which the upper shock mount

can be positioned in. If adjusting the spring pre-load

does not achieve the ride requirement, the shock should

be moved to the next numbered upper shock mounting

position to achieve the desired ride requirement.

• Before adjusting the upper shock mount to a higher

numbered position, you should attempt to achieve the

ride height through the spring pre-load adjustment.

• Shock mounting position #3 should always be used when

a rear mounted grass collection system is installed on the

unit.

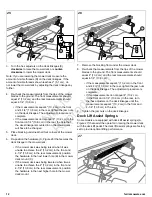

To Adjust the Spring Pre-load:

1. Park the machine on a flat, level surface. Disengage the

PTO, stop the engine, and engage the parking brake.

2. Chock the front wheels to prevent the machine from

rolling. Raise the rear of the machine and secure with

jack stands.

3. Remove the rear drive tires.

WARNING

Spring loaded components can kick back causing injury.

Use two hands when adjusting the shock springs. This will

prevent the wrench from slipping while pressure is being

applied.

4. Using the supplied spanner wrench (p/n 5022853) (B,

Figure 46), insert the tip of the wrench into the notch in

the pre-load adjuster. While holding the wrench in place

with one hand, turn

counter-clockwise

to increase the

pre-load, turn

clockwise

to decrease the pre-load. Make

sure both shocks are set to the same amount of pre-load.

5. Re-install the rear drive tires. Torque the lug bolts to

85-95 ft.lbs. (115-129 Nm). Remove the jack stands from

under the machine.

Note:

If a collection system is installed on the unit it is

recommended that the rear suspension be adjusted stiffer

due to the added weight of the collection system.

To Adjust the Upper Mounting Position (Rear

Shocks):

1. Park the machine on a flat, level surface. Disengage the

PTO, stop the engine, and engage the parking brake.

2. Chock the front wheels to prevent the machine from

rolling. Raise the rear of the machine and secure with

jack stands. The jack stands must be under the bumper

of the machine.

3. Position the jack underneath the rear cross member

of the transmission cradle and slowly raise the rear

suspension to relieve the pressure on the upper shock

mounting bolts.

4. Remove the upper shock mounting hardware and pivot

the shock to the next higher numbered position (see

Figure 46). Adjust the jack to align the shock mounts to

shocks.

5. Remove the jack from under the transmission cradle.

6. Remove the jack stands from underneath the machine.

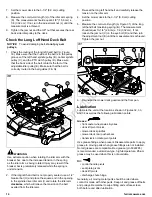

Parking Brake Adjustment

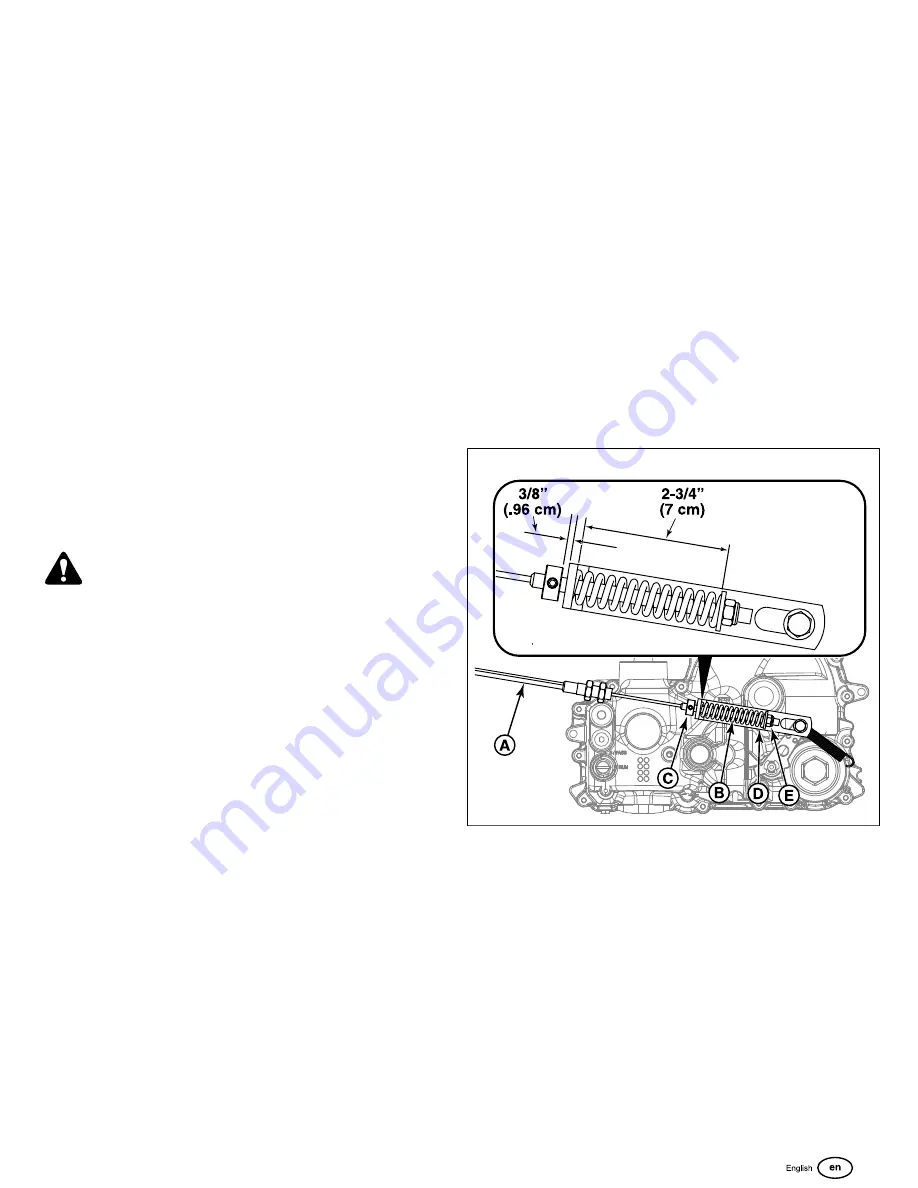

The parking brake mechanism consists of two parking brake

cables (A, Figure 47) that connect the parking brake lever

shaft to the parking brake control arm on the transmissions.

There is a parking brake spring on each parking brake cable

located below the engine deck by the transmission. The

position of the parking brake cable in the rear suspension

cradle is factory preset and should not be changed for parking

brake adjustment procedures. The adjustment is achieved by

changing the compressed spring length of the parking brake

springs.

47

1. Disengage the PTO, engage the parking brake, stop the

engine, and chock the tires.

2. Locate the parking brake springs (B) by the

transmissions.

3. With the parking brake engaged measure the

compressed spring length. The spring should measure

2-3/4" (7 cm) when compressed.

4. If the spring length does not equal the measurement, the

spring length will need to be adjusted.

5. Disengage the parking brake.

6. Loosen the set collar (C) and slide it away from the back

of the parking spring bracket (D).