Not for

Reproduction

13

Simplicity / Massey Ferguson / Snapper ZTR

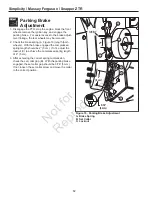

Suspension Adjustment

(select models)

The shock assembly can be adjusted to vary the amount

of pre-load applied to the springs. This allows the opera-

tor to customize the ride according to operator’s weight

and operating conditions.

LESS PRE-LOAD:

• Light operator weight

• Softer, more cushioned ride

• Best for relatively flat terrain

MORE PRE-LOAD:

• Heavy operator weight

• Stiffer, more rigid ride

• Better handling and greater stability on hilly terrain

TO ADJUST THE SPRING PRE-LOAD:

1. Park machine on a flat, level surface. Disengage the

PTO, stop the engine and engage the parking brake.

2. See Figure 17. Turn the pre-load adjustment collar

(A) CLOCKWISE to increase the pre-load, turn

COUNTER-CLOCKWISE to decrease the pre-load.

Make sure both front shocks are set to the same

amount of pre-load. Make sure both rear shocks are

set to the same amount of pre-load.

NOTE: After adjusting the front shock assembly, move

the ring against the adjustment collar to prevent the col-

lar from loosening during operation.

Figure 17. Suspension Adjustment

A. Front Shock Adjustment Collar

B. Rear Shock Adjustment Collar

A

B