5

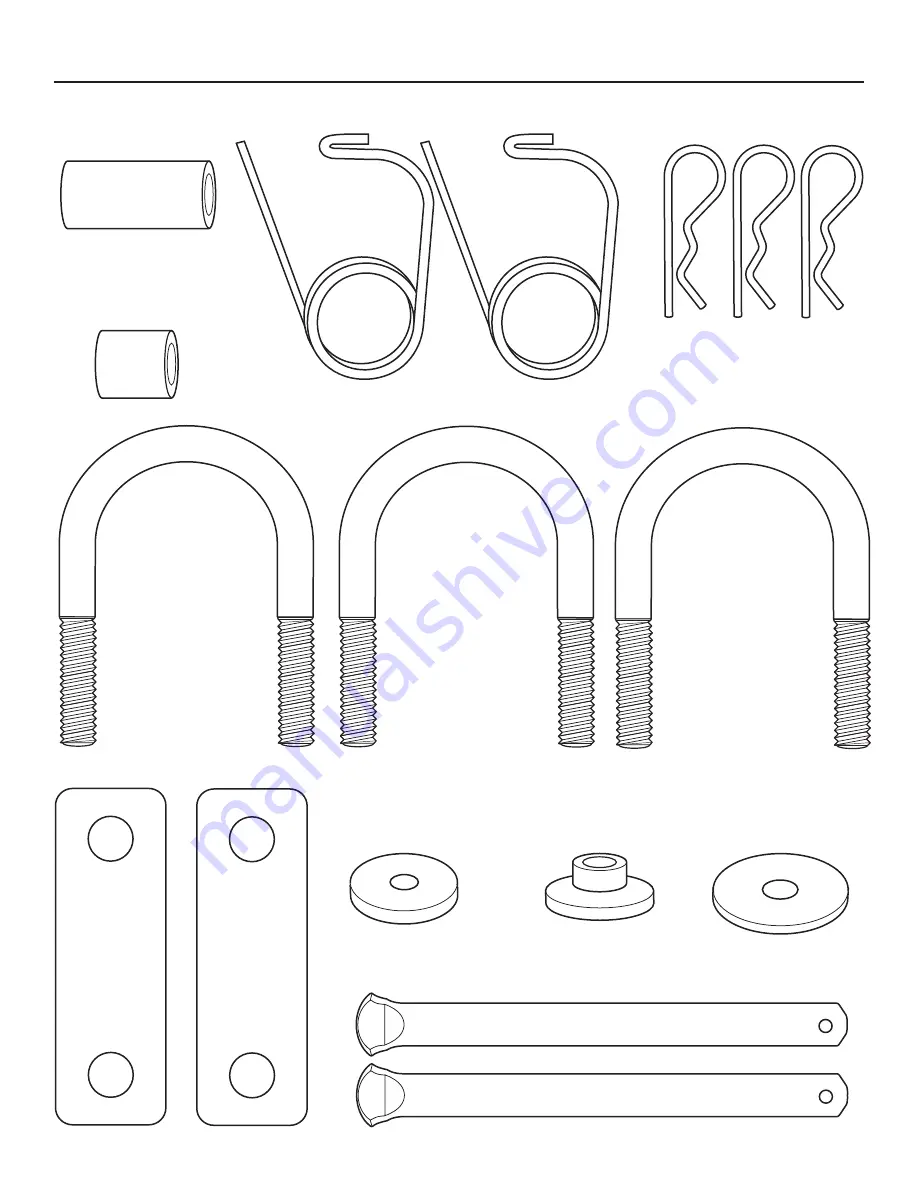

Hardware Bag Contents

N

- SPACER,

.392” ID x .625” OD x .1.32” LG

(Qty. 1)

O

- SPACER,

.390” ID x .625” OD x .687” LG

(Qty. 1)

P

- SAFETY CLIP,

(Qty. 2)

Q

- HAIR PIN,

(Qty. 3)

R

- U-BOLT,

3/8”-16 x 1.125” (Qty. 3)

S

- SPACER,

(Qty. 2)

T

- WASHER,

.34” ID x 1.00” OD x .13” THK

(Qty. 1)

U

- SPACER,

SINGLE STEP

(Qty. 1)

V

- WASHER,

.033” ID x 1.25” OD x .07” THK

(Qty. 1)

W

- COVER HINGE PIN,

(Qty. 2)

No

t fo

r

Rep

rod

uct

ion