1P128

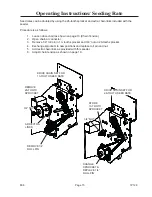

Assembly - Right End Seedshaft & Bearing

Fit the right end of the seed shaft with the bearing plate assembly. If it has not been preassem-

bled, assemble as follows: (See the drawings below.)

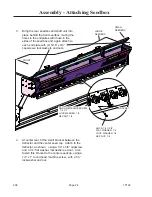

3. Assemble the bearing plate containing the

bearing flangettes and bearing to the end

plate over the seed shaft extension as shown,

with two 3/8” x 3-1/2” tap screws, using the

two lock washers and 7 nuts in the positions

shown. Be sure to fit the pointer onto the

inside tap screw and secure it between the two

3/8” nuts.

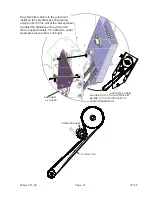

1. Make sure the Number Decal is on

the shaft extension; numbers 0 to 8

should begin near the end plate.

2. Thread the shaft extension onto the end of the seed shaft,

loosely snug down the set screw to secure it (you may

need to adjust the position of the shaft extension later

when adjusting feed cups and seeding rate (it should be

tightened securely at that time), and then thread one 5/8”

nut onto the shaft end of the seed shaft extension.

4. Thread the other 5/8” nut onto the seed shaft extension

on the outside end of the bearing plate until it touches the bearing. Adjusting the posi-

tion of the two 5/8” nuts adjusts the seed rate. See pages 32 and 33 for instructions

on adjusting feed cups, pointer, and seed rate.

FRONT

FRONT

RIGHT SIDE

END PLATE

SHAFT

EXTENSION

NUMBER

DECAL

SET SCREW,

5/16 x 3/8”

NUT, 5/8-11

ASSEMBLED

BEARING

PLATE

POINTER

3/8 HEX NUT

TAP BOLT, 3/8

x 3 1/2”

5/8 HEX NUT

806

Page 29

Summary of Contents for TURFMAKER Junior SLP2041

Page 2: ...1P128 ...

Page 4: ...1P128 ...

Page 24: ...1P128 806 Page 22 ...

Page 25: ...1P128 SECTION II Optional ADDITION OF REAR SEED BOX 806rev7 14 08 Page 23 ...

Page 39: ...1P128 ...

Page 40: ...1P128 ...

Page 41: ......