Document: SLSA-MIP-5-4-0-US

Date of Issue: 05/2016

Revision: -

15-3

15.1

General

This chapter contains information about standard procedures for performing common repairs

of the airplane. These repairs can be made by an authorized organization. Other procedures

for repairing individual airplane systems you can find in the appropriate chapter describing

the system.

NOTE

Before carrying out any structural repairs to contact the relevant airworthiness authority for

approval.

This chapter describes the following procedures:

Removing rivets

Riveting

Repair of skins

Repair of fiberglass parts

Recommendation for repairing surface protection of the airplane

Torque moments

Securing bolt joints and screwed fittings

Repairs of bonding

Installing clamps by Nicopress pliers

15.2

Removing rivets

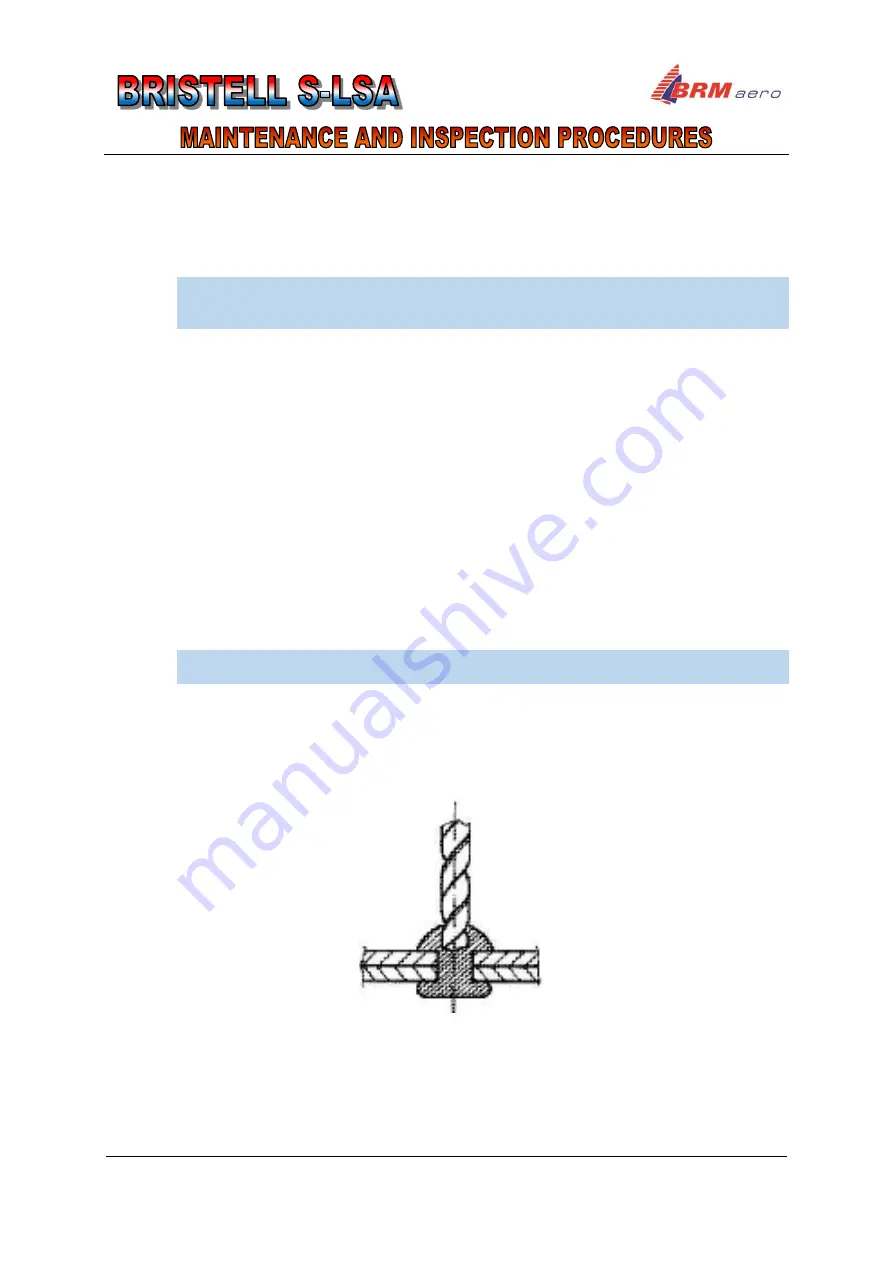

Remove rivets from the side of the rivet, which is more accessible. Drill out the rivet head

and drive out the shank.

NOTE

Center-dot heads of solid rivets, which shall be drilled off.

Use a drill bit of 0.5 mm

(0.025 in)

smaller diameter than the rivet shank and drill up to the

depth of 2/3 of the total depth riveted parts. Remove the drilled heads with a sharp cuter.

Drive out the shank with the soft material mandrel of 0.1 mm

(0.004 in)

smaller diameter than

rivet shank. The rivets, which cannot be driven out should be drilled out full depth. When

removing rivets be careful that chips and rivets do not fall down to areas were sensitive

mechanisms are located, e.g. guides, control bearings etc.

Fig. 15-1

Drilling of rivets (solid rivet shown)

Summary of Contents for S-LSA

Page 2: ......