Document: SLSA-MIP-5-4-0-US

Date of Issue: 05/2016

Revision: -

15-4

15.3

Riveting

15.3.1

General

Riveted parts are used in design of BRISTELL S-LSA airplane for whole fuselage, wings,

flaps, ailerons and tail unit.

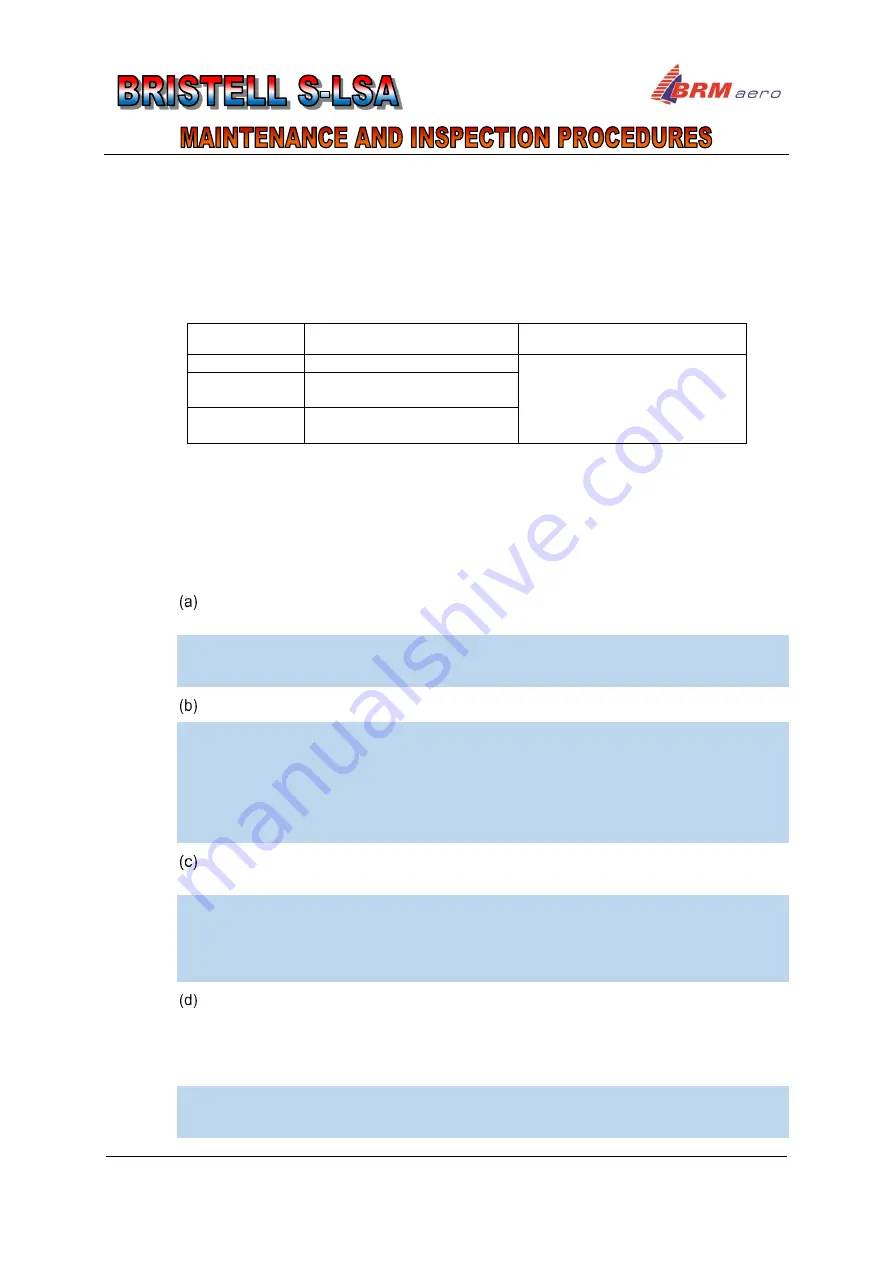

In the following table there is a survey of rivets that are used on BRISTELL S-LSA airplane

structure.

Type of rivets

Designation

Use

AVEX

Aluminum rivet on steel stem

Fuselage, wing, stabilizer,

elevator , rudder, flaps, ailerons

MS20426AD

Aluminum rivet with

countersunk head

MS20470AD

Aluminum rivets with universal

head

Tab. 15-1

Survey of rivets used in airplane structure

In case that different replacement rivets are used than shown in Tab. 15-1 then rivet

dimensions must be identical with originally used rivets and material of rivets must fulfill the

same material characteristics.

15.3.2

Riveting procedure

Fit the parts being connected and drill them together. Hole diameter must be of 0.1 mm

(0.004 in) bigger than rivet shank.

NOTE

When drilling, fix by clamps or clecos mutual position of assembled parts. Holes of higher

diameters predrill with a drill bit of smaller diameter and then redrill them to the final size.

Disassemble the parts and deburr the holes.

NOTE

For sunk rivets perform conical countersinking of the rivet head by 5° smaller apex angle

(e.g. the head with angle of 100° will have countersinking of 95°±1°). After countersinking,

the cylindrical part of hole with min. length of 0.3 mm (0.012 in) must remain in material.

Countersinking must be performed in such a way that the rivets head overruns the area

before riveting max. by 0.2 mm (0.008 in), the rivet head must not be under the surface level

(sunk).

Before applying the bonding sealant carefully clean the connected parts of impurities

and degrease contact surfaces by appropriate agent, e.g. industrial spirit.

NOTE

For cleaning and degreasing use a clean paper towel or cloth. After wiping, the towel or cloth

must not show any contamination. For perfect degreasing the whole surface, clean always

smaller part of surface, after its perfect cleaning continue on. Cleaning liquid always apply

on the cloth only and wipe it off from the surface before its evaporating.

Apply bonding sealant on one of the surfaces, which should be sealed together. Apply

the adhesive directly from the packing by means of the extrusion gun, plastic spatula or

paintbrush in such a way that the layer of sealant is equally thick and integral, without

bubbles or uncovered areas. The optimum thickness of the applied coat is 0.3 mm

(0,01

in)

.

NOTE

The surfaces that are to be connected must be dry and clean before application of bonding

sealant.

Summary of Contents for S-LSA

Page 2: ......