Document: SLSA-MIP-5-4-0-US

Date of Issue: 05/2016

Revision: -

15-17

abrasive having grain size of max. 160 and finish with grain size of 400. It is made by the

sander equipped with the suction from the area of sanding or by manual sanding under water.

CAUTION

Anodized coat cannot be destroyed by sanding on the Al-alloy sheet.

15.6.3.3

Degreasing

It is carried out in the same way as in the case of the total spray coat - see 15.6.2.1.

15.6.3.4

Application of primer

For reaching the satisfactory equal adhesion we recommend to carry out a spray coat of the

place to be repaired by adhesive interlayer (see.Tab. 15-7).

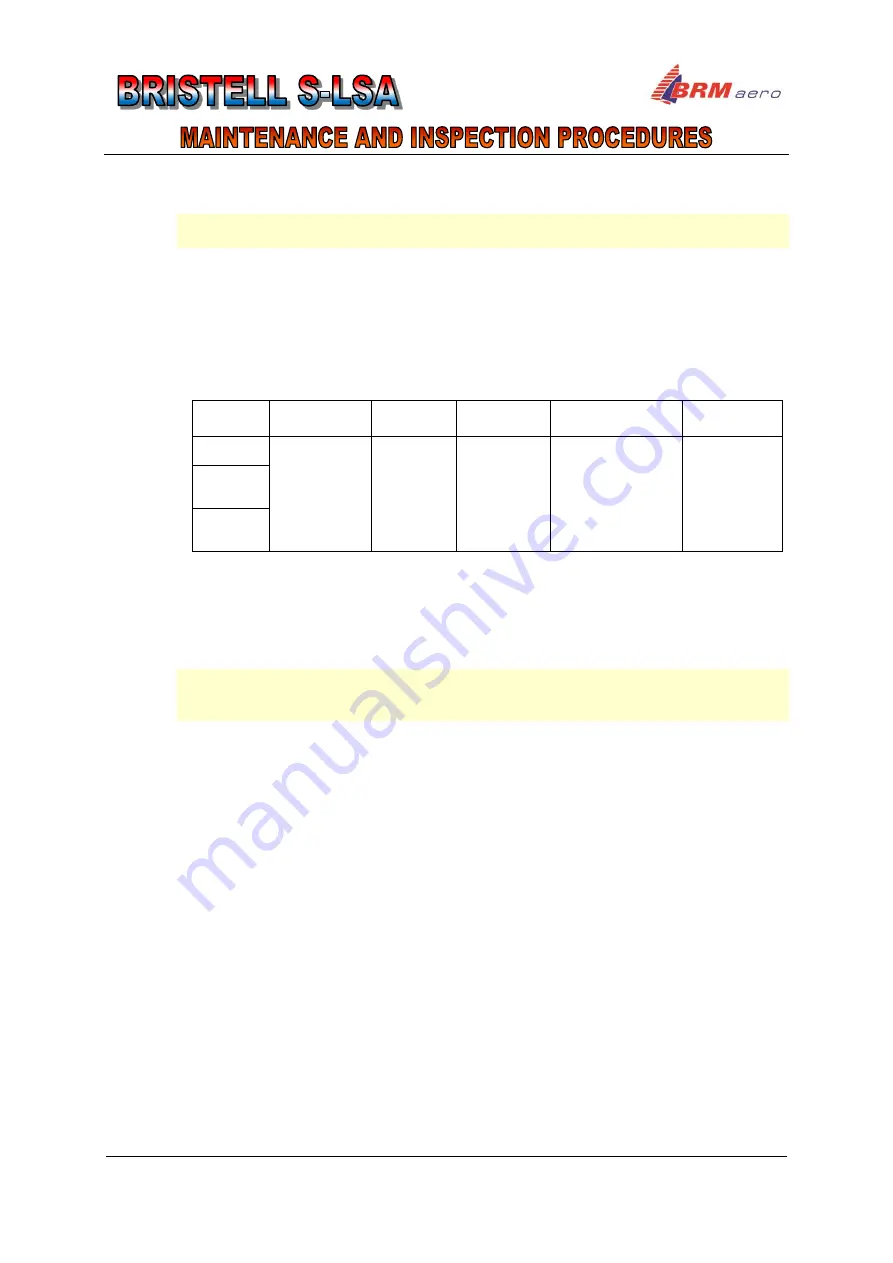

surface

Manufacturer,

name

type

Surface

weight

Recommended

thickness

Drying (total)

18°C (65°F)

Al-alloys

BASF

Glasurit 934-0

single-

component

4.19

[lb/inch/ft

2

]

0.8

[kg/mm/m

2

]

0.00019-

0.00039”

0.005-0.01mm

max 15 min

Epoxy

fiberglass

Old paint

coats

Tab. 15-7

Adhesive interlayer

Subsequently the primer is applied according to Tab. 15-5. Paint coat thickness is given by

necessary thickness of surrounding coats (leveling).

CAUTION

In case that the primer was not removed by the previous step, it is not necessary to apply the

primer again. The original ground primer with adhesive intercoat is enough.

Actual application of primer will be carried out in the same way as for the total spray-coat

(see 15.6.2.3).

Summary of Contents for S-LSA

Page 2: ......