Document: SLSA-MIP-5-4-0-US

Date of Issue: 05/2016

Revision: -

15-19

15.7

Torque moments

Unless otherwise prescribed, the torque moments shown in the following table can be used.

When tightening follow several rules:

Unless specifically stated do not grease neither nut nor bolt.

If possible always tighten the nut. If for some space reasons it is necessary to tighten

the bolt head and the scope of tightening moment is defined. Use higher moment for

tightening.

Maximum moments are used only for the materials and surfaces, which have a sufficient

thickness, area and strength resistant to bursting, warping or other damage. Maximum

tightening moments must not be exceeded.

Bolt size

Torque limits recommended

Max. allowable torque limits

Nm

in lb

Nm

in lb

AN3

2.3 - 2.8

20 - 25

4.5

40

AN4

5.7 - 7.9

50 - 70

11.3

100

AN5

11.3 - 15.8

100 - 140

25.4

225

AN6

18.1 - 21.5

160 - 190

44.1

390

AN7

50.9 - 56.5

450 - 500

94.9

840

AN8

54.2 - 78

480 - 690

124.3

1100

AN9

90.4 - 113

800 - 1000

180.8

1600

Tab. 15-9

Recommended torque values for oil-free, cadmium-plated threads

15.8

Securing the bolt joints

15.8.1

General

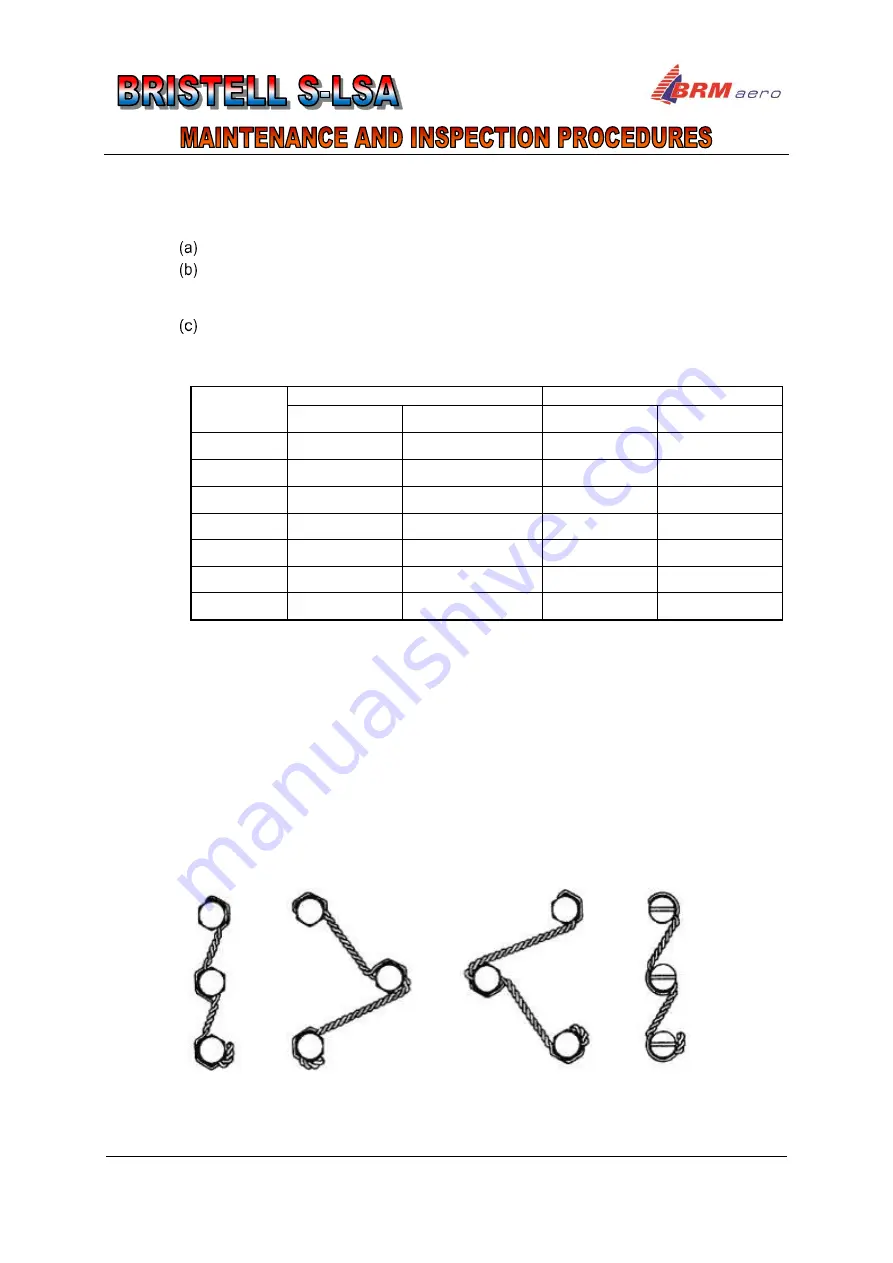

Bolt joint securing is used in order to prevent from their loosening due to vibration or force

action on the connected parts, which could result in the damage of the connected parts.

Three ways of bolt joint securing are used on the airplane: locking wire, cotter pin and locking

washer.

15.8.2

Bolt joint securing by locking wire

Procedure of bolt joint securing is shown on Fig. 15-6 and Fig. 15-7. The zinc-coated or

stainless steel wire having diameter of 0.8 mm (0.032in) is used for securing.

Fig. 15-6

Ways of bolt joint securing

Summary of Contents for S-LSA

Page 2: ......