ENGLISH

OPERATION MANUAL

BRITEQ

®

3/27

LDP-FLOODxx-WW

DESCRIPTION:

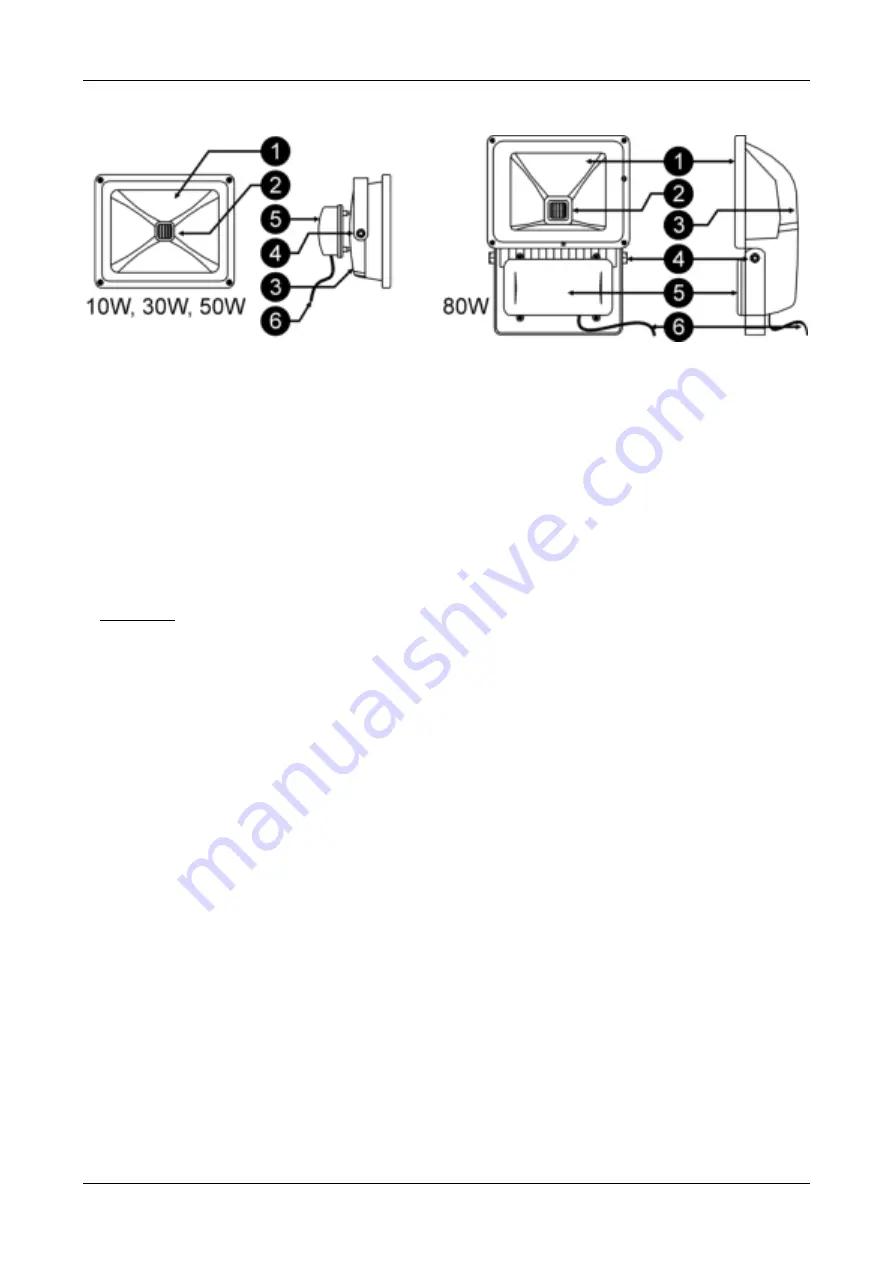

1. GLASS COVER:

tempered glass to keep water from penetrating the housing and protect the LED-cluster

inside. Should be replace immediately when broken!

2. LED CLUSTER:

LED light source size depends on the power of the unit: 10W, 30W, 50W or 80W

3. HEATSINK:

passive cooling of the LED + power supply, make sure the heat sink is never covered. Cool

air ventilation makes sure that the projector will last longer.

4. BRACKET:

Bracket with 3 holes to fix the projector against a wall, ceiling or to the ground. Also a suitable

mounting hook can be used to hang the projector in truss. After fixing the bracket, point the projector in the

right direction and fasten well.

5. POWER SUPPLY:

compartment containing the switching power supply

. Make sure it’s always well closed

to protect the electronics from water infiltration.

6. MAINS CABLE:

3x 1.0mm² power cable with loose ends for fixed installation.

OVERHEAD RIGGING

Important:

The installation must be carried out by qualified service personal only. Improper

installation can result in serious injuries and/or damage to property. Overhead rigging requires

extensive experience! Working load limits should be respected, certified installation materials

should be used, the installed device should be inspected regularly for safety.

Make sure the area below the installation place is free from unwanted persons during rigging, de-rigging

and servicing.

Locate the fixture in a well ventilated spot, far away from any flammable materials and/or liquids. The

fixture must be fixed

at least 50cm

from surrounding walls.

The device should be installed out of reach of people and outside areas where persons may walk by or be

seated.

Before rigging make sure that the installation area can hold a minimum point load of 10times the device’s

weight.

Always use a certified safety cable that can hold 12times the weight of the device when installing the unit.

This secondary safety attachment should be installed in a way that no part of the installation can drop

more than 20cm if the main attachment fails.

The device should be well fixed; a free-swinging mounting is dangerous and may not be considered!

Don’t cover any ventilation openings as this may result in overheating.

The operator has to make sure that the safety-relating and machine-technical installations are approved by

an expert before using them for the first time. The installations should be inspected every year by a skilled

person to be sure that safety is still optimal.