43

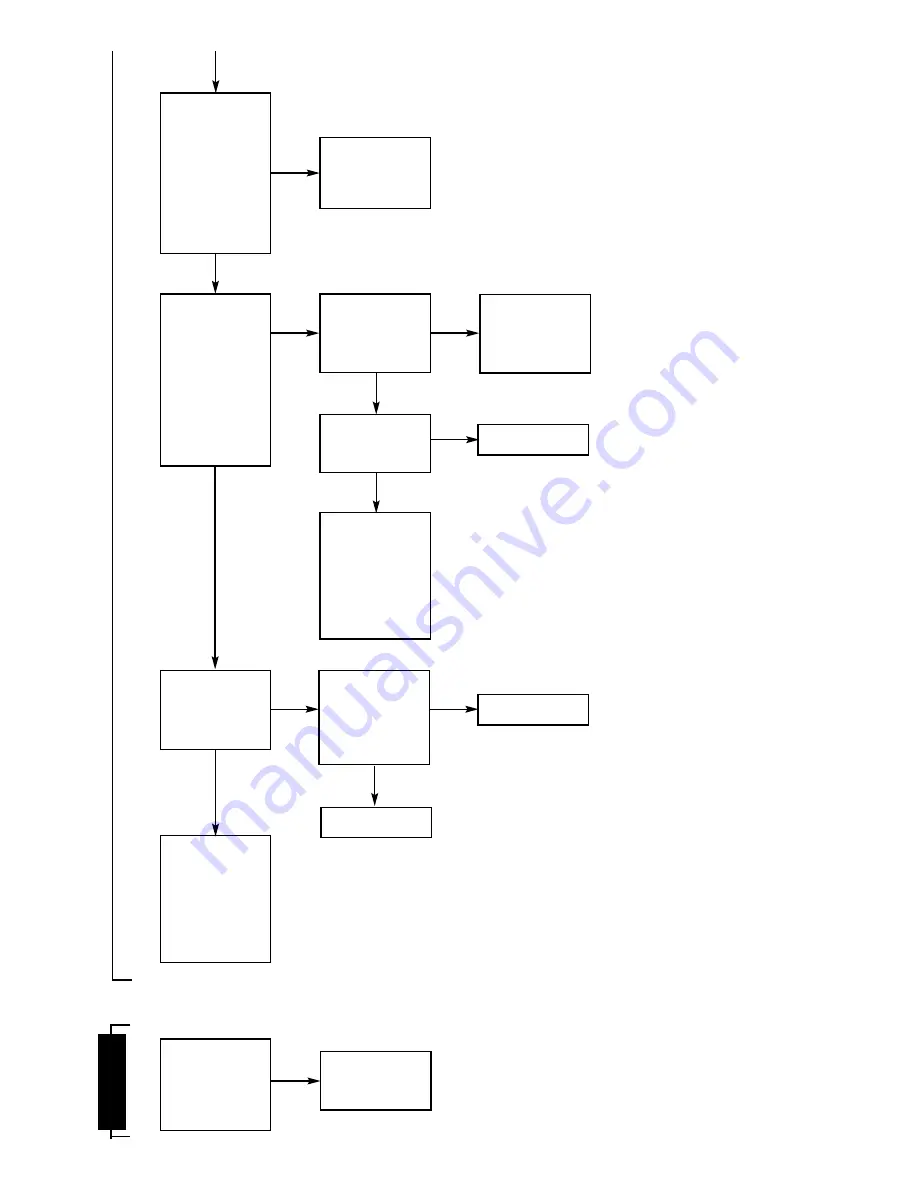

Replace control board.

In the unlikely event

of this not solving the

problem replace code

plug.

Pressure switch has

opened during

operation.

Check flue for

blockage.

Also investigate sense

tubes and pressure

switch.

Replace fan connector

ST1

.

Remove electrical

connectors from air

pressure switch and

reset/restart boiler.

Is there continuity

between

C

and

NO

terminals (where wires

were fitted) when the

fan runs?

(Test within 30

seconds).

Pressure switch has

not closed. Are the

silicon tubes in good

condition and free of

condensation.

Replace air pressure

switch.

Note: In the unlikely

event of this not

solving the problem

inspect the pressure

pick-up (Venturi) in the

fan or fan may not be

running freely.

Inspect the flue. Is it

free of any

restrictions?

Rectify flue problem.

Does the burner ignite

(burner light on) and

run for a short priod

before the fault

occurs?

Replace control board.

Repair cables or

replace main harness.

Replace tubes. If

condensation has

occurred, also replace

pressure switch and

check condition of

Venturi in the fan.

No

No

No

No

Yes

Yes

Yes

Yes

Turn to 'NORM'

position

The gas valve mode

switch (concealed by

the facia side panel)

is not set correctly

TEST F

Replace multiway

connector to position

ST16

(but not fan

connector at

ST1

) and

reset/restart the

boiler.

Is there mains 230V

across the right (

L

)

and left (

N

) tracks at

board position

ST1

?

NOTE:

Take care not to

short

L

to

N

.

Yes

Remove multiway

connector from board

position

ST16

.

Is there continuity of

black & blue cables to

the air pressure

switch?

No

No

Yes

Yes

Summary of Contents for RD 628

Page 34: ...34 1 2 3 4 7 5 6 8 9 10 11 12 4 15 13 16 19 14 17 18 20 22 23 21 ...

Page 45: ...45 ...

Page 46: ...46 ...

Page 47: ...47 ...

Page 51: ......

Page 53: ......

Page 55: ...L2 0mm ...

Page 57: ......

Page 58: ...RD 628 USER INSTRUCTIONS CUSTOMER CARE GUIDE G C NUMBER 47 108 14 ...

Page 71: ...14 ...