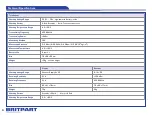

Technical Specifications

6

Tyre Sensor

Working Voltage Range

DC 2.1 – 3.6v - High-powered battery inside

Working Current

0.6uA - Standby / 9mA - Transmission status

Working Temperature Range

-40–125ºC

Transmitting Frequency

433.92MHz

Transmitting Power

>5dBm

Modulating Method

FSK

Measurable Pressure

0–3.5bar (0–350KPa/0–50.8psi/0–3.58*10

4

kgf/m

2

)

Measurable Temperature

-40–+120ºC

Battery Life

5 years +

Size

76 x 56 x 22mm

Weight

<38g - no valve weight

Display

Receiver

Working Voltage Range

Receiver Supply 5v DC

9–15v DC

Receiving Sensitivity

N/A

<-100dBm

Receiving Frequency

N/A

433.92MHz

Size

83 x 41 x 18mm

75 x 55 x 17mm

Weight

70g

35g

Working Current

Standby - <30mA / Alarm - <80mA

Working Temperature Range

-30 – +80ºC