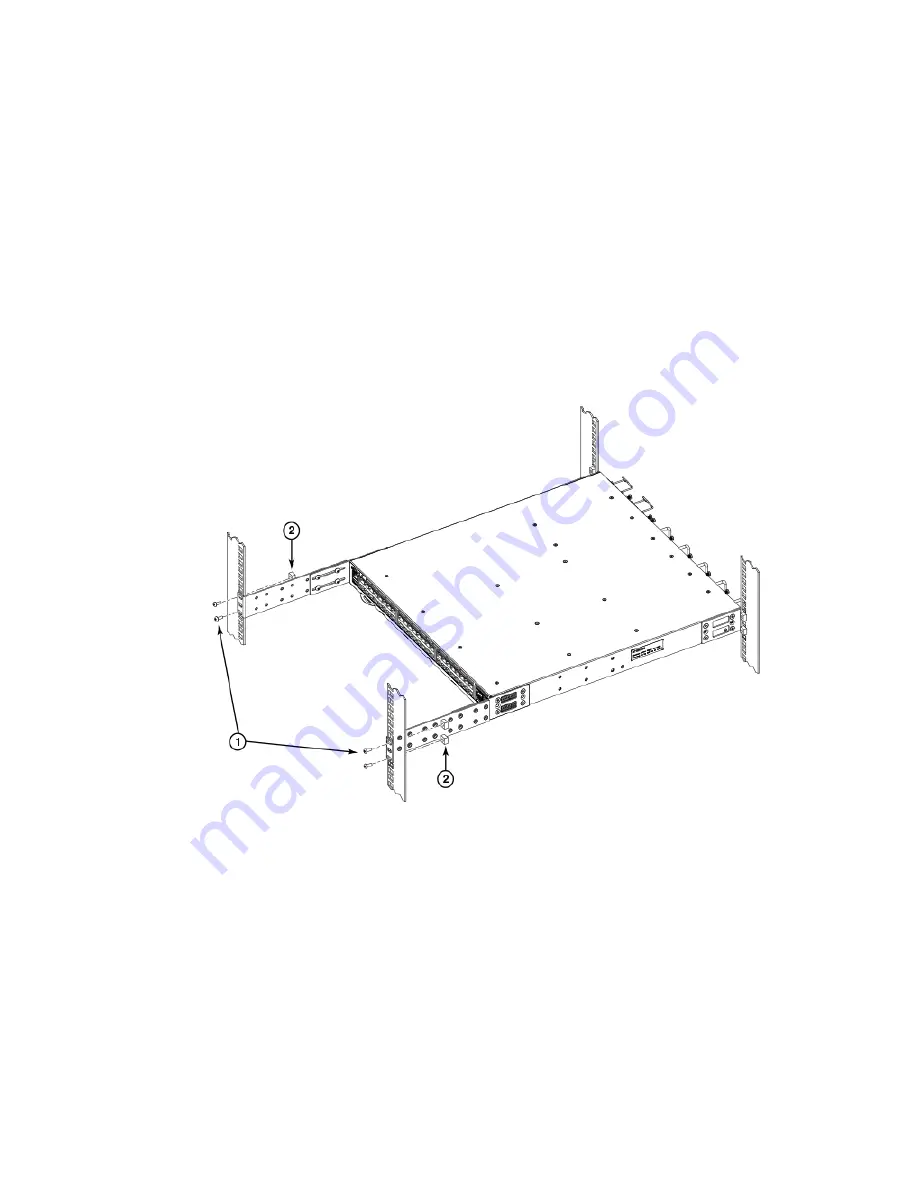

1.

Rear bracket, short or long

2.

Screws, 6-32 x 1/4-in., panhead Phillips

Attaching the rear brackets to the front rack posts

Complete the following steps to attach the rear brackets to the front rack posts.

1. Attach the right rear bracket to the right front rack post using two 10-32 x 5/8-in. screws and two retainer nuts, as shown in

. Use the upper and lower holes in the bracket.

2. Attach the left rear bracket to the left front rack post using two 10-32 x 5/8-in. screws and two retainer nuts. Use the upper and

lower holes in the bracket.

3. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb (29 cm-kg).

FIGURE 14

Attaching the rear brackets to the front rack posts

1.

Screws, 10-32 x 5/8-in., panhead Phillips

2.

Retainer nuts, 10-32

Installing the Universal Two-Post Rack Kit (XBR-

R000294)

Use the following instructions to install a Brocade 1U or 2U device in a two-post telecommunications (Telco) rack using the Universal

Two-Post Rack Kit (XBR-R000294).

There are two ways you can mount the device in a two-post rack:

•

With the port side flush with the front posts

•

With the posts mounted to the mid-section of the device

Installing the Universal Two-Post Rack Kit (XBR-R000294)

Brocade G630 Hardware Installation Guide

53-1005235-02

37

Summary of Contents for Brocade G630

Page 10: ...Brocade G630 Hardware Installation Guide 10 53 1005235 02 ...

Page 22: ...Brocade G630 Hardware Installation Guide 22 53 1005235 02 ...

Page 48: ...Brocade G630 Hardware Installation Guide 48 53 1005235 02 ...

Page 72: ...Brocade G630 Hardware Installation Guide 72 53 1005235 02 ...

Page 88: ...Brocade G630 Hardware Installation Guide 88 53 1005235 02 ...

Page 96: ...Brocade G630 Hardware Installation Guide 96 53 1005235 02 ...

Page 100: ...Brocade G630 Hardware Installation Guide 100 53 1005235 02 ...