MODEL B5936SS

Page 6

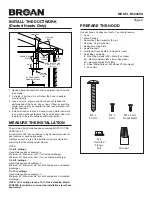

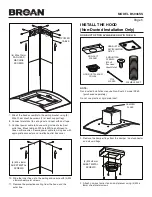

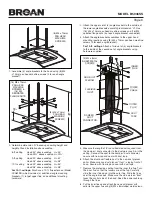

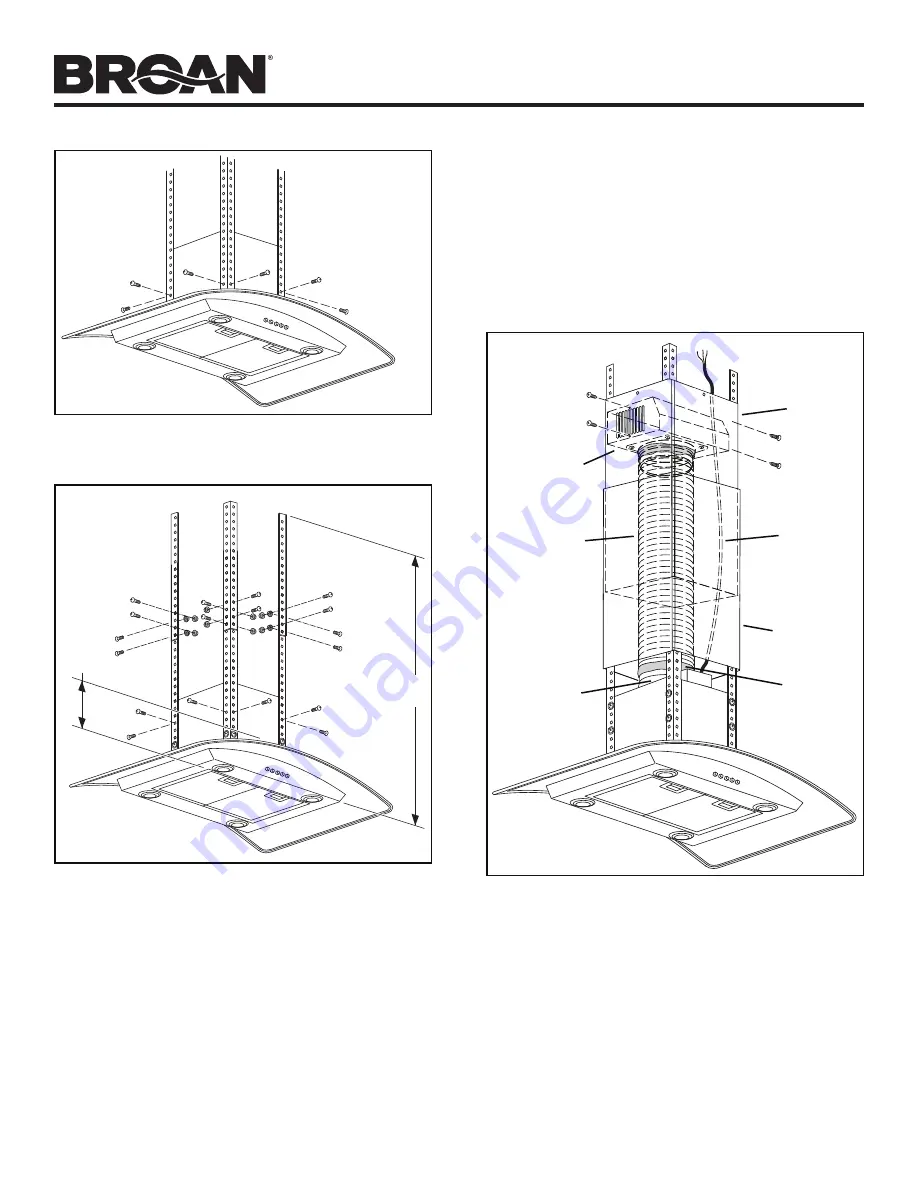

5. Measure the length of 6” round flexible duct required from

the damper / duct connector to the ductwork rough-in in the

ceiling. Connect the duct to the damper / duct connector,

secure with tie wrap and seal with duct tape.

6. Attach the aluminum flexible duct to the non-duct plenum

collar. Make sure non-duct plenum “front” is facing front of

hood. Secure with tie wrap and seal with duct tape.

7. Remove the protective coating from the inner the flue. Turn

the inner flue so that the louvers are at the top. Carefully

slide the inner flue down into the outer flue. Slide the flues

over the angle brackets. Make sure the side marked “front”

faces the control side of the hood. Feed the power cable up

through the flues.

8. Pull the inner flue up and attach the non-duct plenum with

collar to the upper flue using (4) M4 x 8mm sheet metal screws.

FRONT

(4) M4 x 8mm

SHEET METAL

SCREWS

INNER

FLUE

OUTER

FLUE

FLEXIBLE

DUCT

DUCT

TAPE

DAMPER /

DUCT

CONNECTOR

POWER

CABLE

NON-DUCT

PLENUM

(8) M4 x 10mm

PAN HEAD

MACHINE

SCREWS

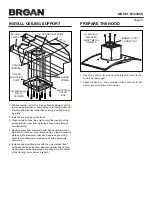

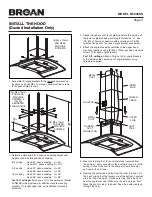

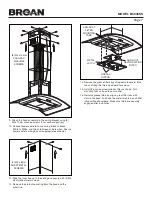

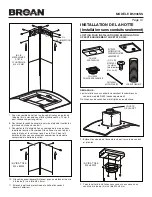

1. Assemble (4) angle brackets to the hood using (8) M4

x 10mm pan head machine screws (2 for each angle

bracket).

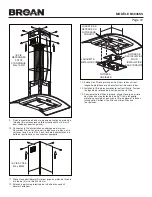

2. Determine dimension “H” based upon ceiling height and

height of hood installation above cooktop:

8-ft. ceiling

Hood 30” above cooktop H = 30”

Hood 30½” above cooktop H = 29½”

9-ft. ceiling

Hood 30” above cooktop H = 42”

Hood 36” above cooktop H = 36”

10-ft. ceiling Hood 30” above cooktop H = 54”

Hood 36” above cooktop H = 48”

For 10-ft. ceilings: Purchase a 10-ft. flue extension (Model

FXN59SS) which includes (4) additional angle mounting

brackets, (1) longer upper flue, and additional mounting

hardware.

H

3”

(16) M4 x 10mm

PAN HEAD

MACHINE

SCREWS &

(16) M4

SERRATED

FLANGE NUTS

(8) M4 x 10mm

PAN HEAD

MACHINE

SCREWS

3. Attach the upper set of (4) angle brackets to the outside of

the lower angle brackets according to dimension “H”. Use

(16) M4 x 10mm pan head machine screws and (16) M4

serrated flange nuts (4 at each angle bracket connection).

4. Attach the angle bracket assemblies to the upper hood

mounting locations using (8) M4 x 10mm pan head machine

screws (2 for each angle bracket).

For 10-ft. ceilings: Attach a third set of (4) angle brackets

to the inside of the second set of angle brackets using

hardware supplied.