2

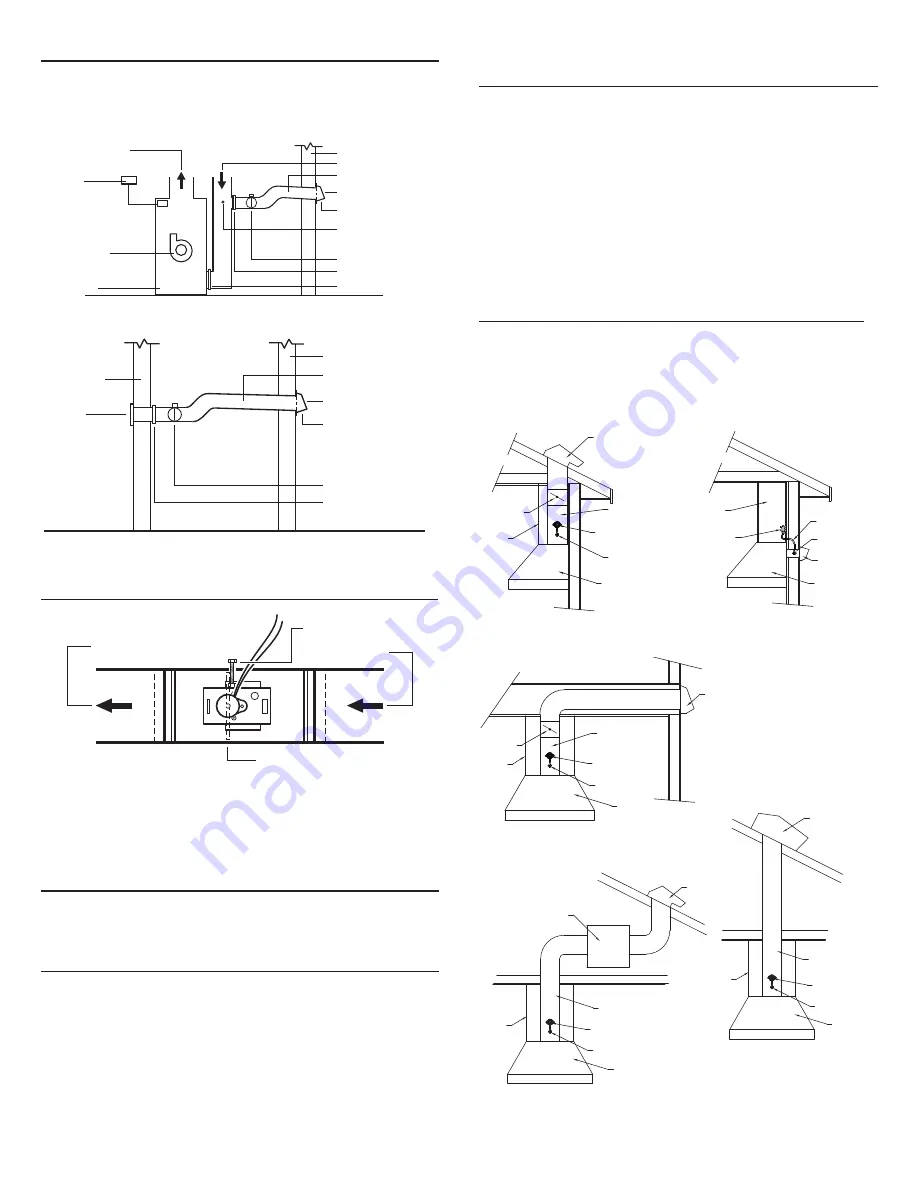

Damper and outside air duct connected directly to a ceiling, floor, or wall register.

INTERIOR WALL

WALL

REGISTER

REGISTER BOX ADAPTED

WITH SLIDE-IN FILTER (optional)

MOTORIZED DAMPER

WALL CAP WITH

BIRD SCREEN

INSULATED OUTSIDE

AIR DUCT (slope toward wall cap)

EXTERIOR WALL

VENTILATION AIR INTAKE

(locate away from pollutant sources)

TYPICAL INSTALLATIONS

Installations will vary according to the location in the home where the unit is installed

and which model Damper is used. Use the following illustrations and notes as guidance

for your own installation. Always comply with local code requirements and in any

instance where a detail shown below conflicts with local code, the local code provision

shall apply.

Damper connected to return side of central duct system.

AIR HANDLER UNIT

AIR DISTRIBUTION FAN

THERMOSTAT

CENTRAL SYSTEM SUPPLY AIR

REGISTER BOX ADAPTED

WITH SLIDE-IN FILTER (optional)

AUTO. MAKE-UP AIR DAMPER

FIELD MEASUREMENT OF AVAILABLE

STATIC PRESSURE. (See “Install The

Damper” section on page 3 for damper

balancing instructions.)

FRESH AIR INLET WALL CAP

WITH BIRD SCREEN

INSULATED OUTSIDE

AIR DUCT (slope toward wall cap)

EXTERIOR WALL

VENTILATION AIR INTAKE

(locate away from pollutant sources)

CENTRAL SYSTEM RETURN AIR

CENTRAL DUCT SYSTEM FILTER

INSTALL THE DAMPER

OUTSIDE AIR

TO CENTRAL SYSTEM

RETURN AIR OR INTERIOR

WALL REGISTER

DAMPER FLAP (Install in

vertical position shown.)

AIR FLOW

AIR FLOW

SET SCREW

Install the damper as shown. Make sure damper flap is in a vertical position when

closed and power is off. The set screw can be used to adjust the damper opening -

thereby balancing the inside and outside air pressure when the range hood exhausts

at high speed.

PRESSURE SWITCH OPERATION

The pressure switch is designed to operate when the static pressure increases to 0.05”

Ps or more. It may not operate at low speeds since the pressure is below this limit.

MULTIPLE DAMPERS

More than one damper may be required to balance the system. If more than one is

required use (1) MD6TU or MD8TU and then use the MD6 or MD8 dampers as ad-

ditional dampers.

INSTALLATION OF PRESSURE SWITCH

AND PROBE

For the probe & pressure switch to work effectively the roof or wall cap must have a

spring loaded damper. The following Broan products are recommended:

TYPICAL INSTALLATION WITH

INTERNAL BLOWER AND ROOF VENT

RANGE

HOOD

PROBE

EXHAUST

DUCT

ROOF CAP

w/DAMPER

PRESSURE

SWITCH

HOOD

FLUE

IN-LINE

DAMPER

TYPICAL INSTALLATION WITH

INTERNAL BLOWER AND WALL VENT

RANGE

HOOD

PROBE

EXHAUST

DUCT

PRESSURE

SWITCH

HOOD

FLUE

WALL CAP

w/DAMPER

IN-LINE

DAMPER

TYPICAL INSTALLATION WITH

INTERNAL BLOWER AND HORIZONTAL

DUCTING w/ WALL VENT

RANGE

HOOD

WALL CAP

w/DAMPER

PROBE

TUBING

PRESSURE

SWITCH

KITCHEN

CABINET

TYPICAL INSTALLATION WITH INLINE BLOWER

RANGE

HOOD

PROBE

EXHAUST

DUCT

PRESSURE

SWITCH

HOOD

FLUE

ROOF CAP

w/DAMPER

INLINE

BLOWER

TYPICAL INSTALLATION

WITH EXTERIOR BLOWER

RANGE

HOOD

PROBE

EXHAUST

DUCT

PRESSURE

SWITCH

HOOD

FLUE

EXTERIOR

BLOWER

Wall Cap models:

WC638 – For 3¼” x 14” duct

639 / 649 – For 3¼” x 10” duct

647 – For 7” round duct

843BL / 641 – For 6” round duct

643 / 643FA – For 8” round duct

613 – For 12” round duct

441 – For 10” round duct.

Roof Cap models:

437 – High capacity up to

1200 cfm

634 / 644 – For 3¼” x 10” and

up to 8” round

634M – For 6” round

LOCATION OF PROBE AND

PRESSURE SWITCH

The probe must be mounted between the range hood damper and the wall cap, roof

cap, in-line blower or external blower. Mount the probe as close to the hood outlet as

possible but make sure the hood damper operation is not affected.

The pressure switch should be mounted so it is accessible for any future service.

The switch can mounted no more then 72” away from the probe. If longer tubing is

required then what is supplied, purchase 1/4” I.D. PVC tubing from a local source.

See the illustrations below for possible installation scenarios.