3-11

11. Tighten compression nut (25).

12. Reconnect red and yellow wires (23).

13. Replace controller, front panel and

condensate pan.

14. Replace capillary guard (18).

15. Return cooking oil to cooking well.

16. See CALIBRATION.

17. Cook a load and check for leaks.

18. Tighten compression nut (25) if neces-

sary.

Replacement 2400E:

1. See ACCESS FOR SERVICE.

2. Disconnect probe (23) wires.

3. OPEN cover. Drain cooking oil from

cooking well. Close drain valve.

4. Remove capillary guard (18) inside of

cooking well.

5. Remove basket guide (27) inside of

cooking well.

6. Slide item (27) off of Temperature Sen-

sor probe (28). Note where probe bend

is located. Placement is important.

7. Loosen compression nut (25).

8. Remove fitting (26) from reducer fitting

(20).

9. Remove reducer fitting (20) from out-

side of the cooking well.

10. Carefully pull probe out of cooking

well.

11. Install new probe in the same location

as old probe. Slide guide (27) onto

probe and assemble noting dimen-

sions for locating probe (28). See Fig.1

below.

broaster.com Manual #15460 8/02 Rev 7/14

Summary of Contents for 2004E

Page 2: ......

Page 8: ......

Page 12: ......

Page 21: ...2 9 MODEL 2400GH DOMESTIC MODEL 2400GHXP EXPORT broaster com Manual 15460 8 02 Rev 7 14 ...

Page 22: ...2 10 MODEL 2400GHCE EU broaster com Manual 15460 8 02 Rev 7 14 1 2 2 1 2 1 ...

Page 44: ......

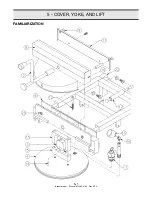

Page 45: ...5 COVER YOKE AND LIFT 5 1 FAMILIARIZATION broaster com Manual 15460 8 02 Rev 9 14 ...

Page 54: ......

Page 81: ...9 9 This page intentionally left blank broaster com Manual 15460 8 02 Rev 3 16 ...

Page 87: ...broaster com Manual 15460 8 02 SERVICE NOTES ...

Page 88: ...broaster com Manual 15460 8 02 SERVICE NOTES ...

Page 89: ...broaster com Manual 15460 8 02 SERVICE NOTES ...

Page 90: ......

Page 91: ......

Page 92: ...Broaster Company 2855 Cranston Road Beloit WI 53511 3991 608 365 0193 broaster com ...