6-3

EXHAUST TUBE

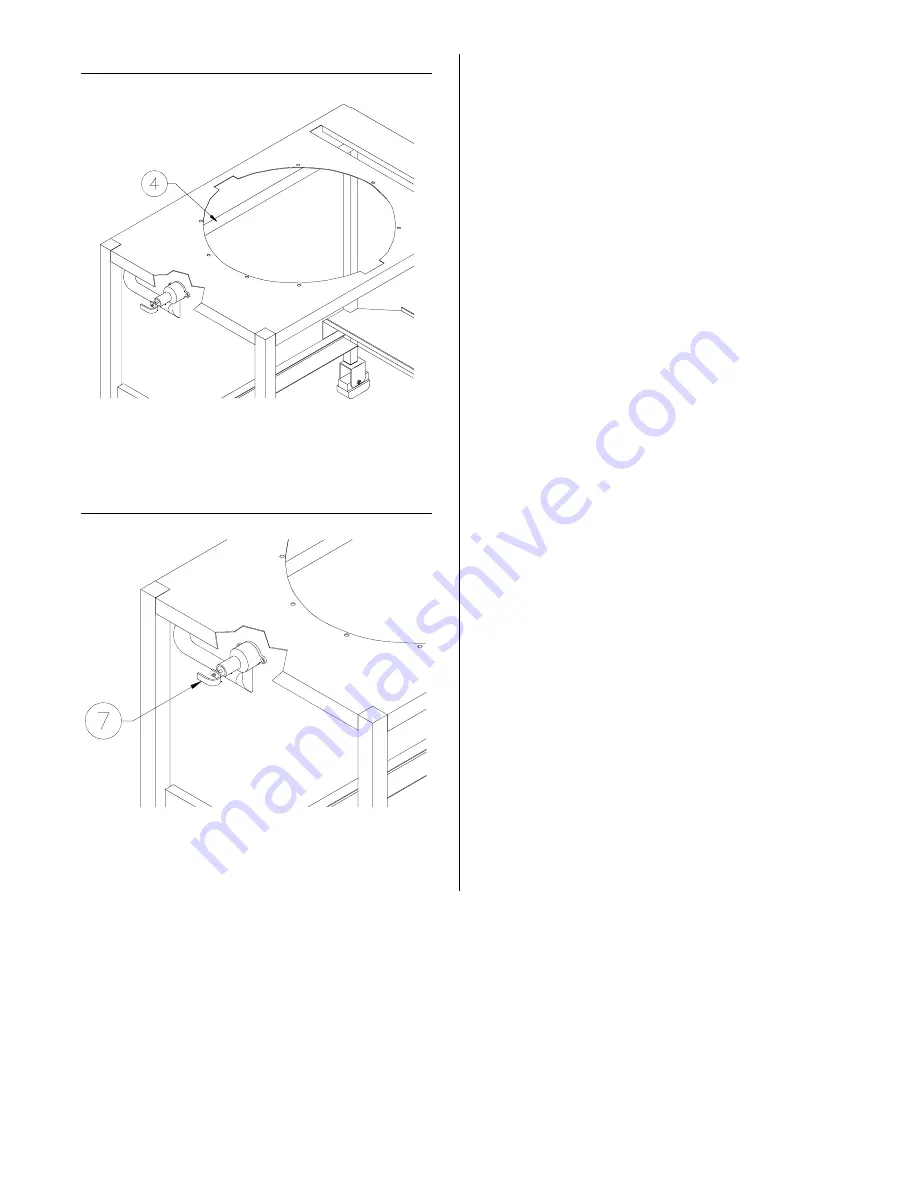

Tube (4) directs steam and vapors from

cooking well into the exhaust tank.

PRESSURE REGULATING VALVE

Valve (7) is preset to maintain a maximum

pressure of 12-14 psi during a cooking

cycle. Pressure may build slowly or remain

low when cooking small loads. Add one or

two quartered potatoes with product to

help build and maintain maximum pressure.

Replacement:

1. Disconnect main electric power sup-

ply.

2. Slide right hand squeeze clamp, on

valve outlet, to the left.

3. Pull silicone sleeve and exhaust tube

(4) free of valve outlet.

4. Remove two allen screws mounting

valve to the cooking well and remove

valve.

5. See

Repair

.

6. Install silicone sleeve and exhaust

tube onto the valve outlet.

7. Slide right hand squeeze clamp onto

the valve outlet.

broaster.com Manual #17280 1/15

Summary of Contents for 2400 Series

Page 2: ......

Page 8: ......

Page 12: ......

Page 14: ...2 2 2400E 208 or 240VAC C NO NC broaster com Manual 17280 1 15 ...

Page 15: ...2 3 2400GH NO NC C broaster com Manual 17280 1 15 ...

Page 16: ......

Page 35: ...5 COVER YOKE AND LIFT 5 1 FAMILIARIZATION broaster com Manual 17280 1 15 ...

Page 44: ......

Page 70: ......

Page 71: ...broaster com Manual 17280 1 15 SERVICE NOTES ...

Page 72: ...broaster com Manual 17280 1 15 SERVICE NOTES ...

Page 73: ...broaster com Manual 17280 1 15 SERVICE NOTES ...

Page 74: ...broaster com Manual 17280 1 15 SERVICE NOTES ...

Page 75: ......

Page 76: ...Broaster Company 2855 Cranston Road Beloit WI 53511 3991 608 365 0193 broaster com ...