10

RESISTANCE RATING

SUPPORTING ELEMENT

EI 180 S - 500 Pa

EI 120 S - 500 Pa

EI 90 S - 500 Pa

NORMALISED BRICK WALLS MIN. WIDTH 150

(V

e

i

Q

o)

da Ø 200 a Ø 800

SE

da Ø 200 a Ø 800

MA / SE

da Ø 200 a Ø 800

MA / SE

LIGHT WALL MIN. WIDTH 100

(V

e

i

Q

o)

da Ø 200 a Ø 630

MA / SE

da Ø 200 a Ø 630

MA / SE

HORIZONTAL FLOOR MIN. WIDTH 150

(h

O

i

Q

o)

da Ø 200 a Ø 800

MA

da Ø 200 a Ø 800

MA / SE

da Ø 200 a Ø 800

MA / SE

IT

ENG

REGULATORY FRAMEWORK

Fire Damper certified to EN 1366-2 Standards (M.D. 16/02/2007)

and rated according to UNI EN 13501-3 Standard requirements.

Key

E = integrity

I = thermal insulation

S = fume seal

V

e

= vertical installation

h

o

= horizontal installation

i

Q

o = side exposed to fire indifferent

HANDLING AND INSTALLATION WARNINGS

Warning!

• All handling and installation operations must be conducted with the fire damper shutter in a closed position (as per

our standard supply)

• All connections to the mains must be done by professionally qualified personnel

• Clean and remove all cement residues from the connection flanges to ensure secure connections to the rest of the

duct

• Avoid all deformation of the duct and/or obstacles inside the duct that could prevent correct rotation of the shutter

• Check there are no external objects (cables, pipes, etc.) which could prevent the correct operations of the commands

outside the duct itself

• Keep as much access clearance as possible on the control unit side so as to ensure the user and maintenance opera-

tors have sufficient space to work on the damper

MAINTENANCE

No special maintenance is required. It is however recommended to check that all shutter operating and warning de-

vices are working properly on a regular basis.

More specifically, check for complete and correct opening and closing of the shutter blade: for information on how to

enable the commands, please refer to the “COMMAND FUNCTION” paragraph on page 5 of this manual.

Also check that the limit switch warning devices for start and end strokes (where applicable) are in good working

condition.

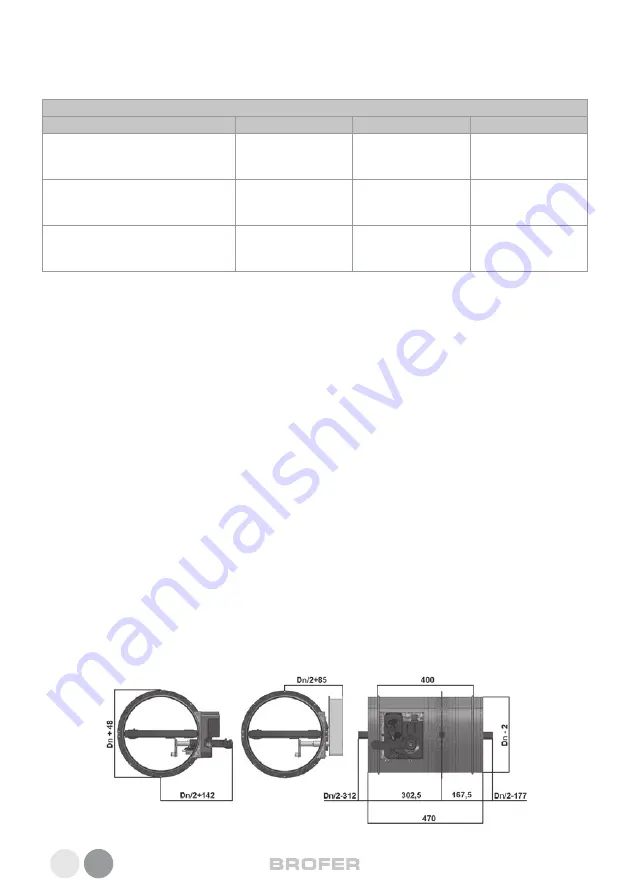

DIMENSIONAL