15

IT

ENG

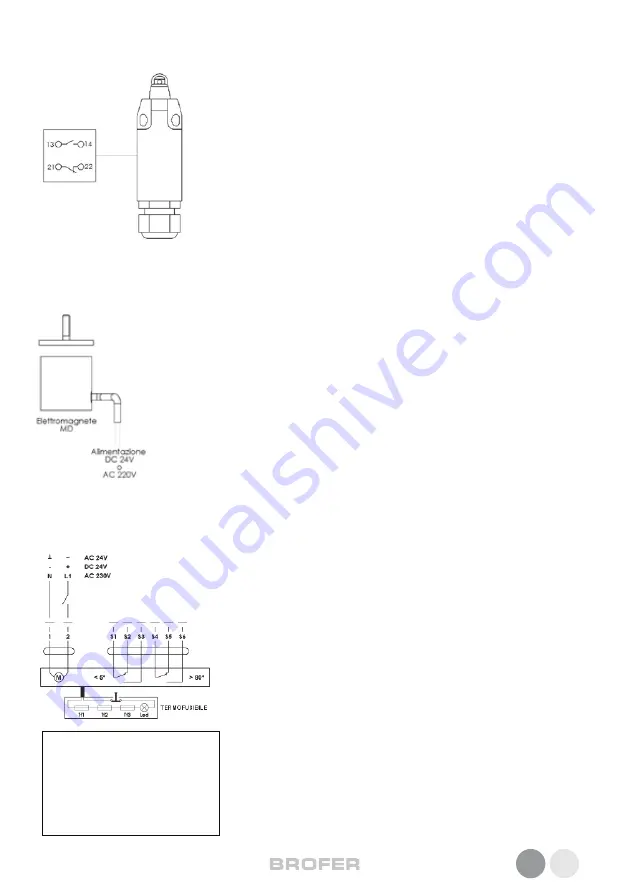

Magnetic command

Where necessary, an electromagnet can be installed on the damper so as to anticipate the clos-

ing of the damper before the thermo fuse is triggered. Depending on the type of electromagnet

(current input or breaker), it will send or cut off the electric power signal and the damper will

close to prevent the diffusion of cold fumes.

If a fire breaks out, when the temperature rises the thermo fuse will override the action of the

electromagnet.

Magnet technical specs

- Retaining force: 120N

- Protection rating (EN 60529 Standard): IP40

- Absorbed current at 20°C: 1.6W (none) - 3.5W (emission)

- Operating temperature: from -30 to +85

MOTORISED COMMAND FUNCTIONS, DATA AND ELECTRICAL WIRING LAYOUT

The motor is powered by connecting it to the mains (contacts 1 and 2) which

moves the damper shutter to the open position, whilst simultaneously loading

the spring which retains all the power needed to close the duct in case of and

alarm or black-out.

The connections of the two limit switches inside the motor can be used to ren-

der the rest of the system more flexible; for instance, by connecting contacts

S1 and S2, it will be possible to trigger the shutdown of the fan unit should

the damper shutter close, whilst contacts S4 and S6 can be used to trigger

an alarm pilot light.

The thermoelectric device consists of three fuses: these make the fire damper

shutters sensitive to the temperature inside the duct (with Tf 2 and Tf 3 fuses

which can be replaced) and to ambient temperatures (using the Tf 1 fuse).

When the device is triggered, it locks down the power supply irreversibly, until

the fuses are replaced, which allows the servomotor to move the shutter into

the closed position using the force of the spring.

It also has a button that can be pressed manually to simulate a triggered fuse

and allow testing and inspection of the shutter.

Its position outside the damper and self-threading screw fasteners allows for

safe control over ambient temperatures and easy maintenance.

• Allacciamento 24V:

da trasformatore

• Allacciamento 230V:

per l’interruzione della rete prevedere

un dispositivo di sezionamento di

tutte le fasi (apertura dei contatti

min. 3mm)

MANUAL COMMAND FUNCTIONS, DATA AND ELECTRICAL WIRING LAYOUT

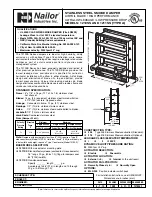

Start and end stroke microswitches

The devices that signal the start stroke and end stroke are two independent NC+NO

dual contact switches.

The first normally closed (NC) on contacts 21 and 22, whilst the second normally

open (NO) on contacts 13 and 14.

When the switch is triggered, the contact status is inverted, the NC contact opens

and the NO contact closes.

E.g.: the relay that controls the fan power supply is connected to contacts 21 and 22

(NC), whilst a luminous alarm indicator is connected to contacts 13 and 14 (NO). In

this case, when the damper shuts, the fan will switch off and the alarm indicator

pilot light will come on.

Switch technical data

-Casing: Fibre glass reinforced thermoplastic

-Protection rating (EN 60526 Standard): IP65

-Cable cross-section diameter: rigid 2.5mm² - flexible with ferrule 1.5 mm²

Operating temperature: from -25 to +70