9

Manual command with input electromagnet

Reset:

• Raise the metal lever on the control unit casing (fig.1).

• Remove the reset lever from the housing compartment (fig.2).

• Insert the reset lever inside the control pin as far as possible, turning the lever clockwise by 90 degrees, making sure

that the control pin is blocked in the open position (fig.3).

• Now remove the lever from the control pin and replace it in its housing compartment.

Manual closing:

• Press the button highlighted in fig.4.

Electromagnetic closing:

• Power up the electromagnet.

Servomotor mode

Reset:

• Insert the key supplied with the delivery into the housing on the servomotor and turn it clockwise to a 90 degree

position.

• Quickly rotate it counter clockwise to block the servomotor in the open position.

• Manual closing:

• Insert the key supplied with the delivery into the housing on the servomotor and turn it counter clockwise by half a

turn to enable the spring return that will automatically move the servomotor into the closed position and the relative

indicator in a 0 degree position.

Motorised closinga:

• Move the thermoelectric fuse lever located to the side of the servomotor or disconnect the power supply.

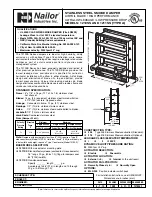

fig. 1

fig. 1

fig. 2

fig. 2

fig. 3

fig. 3

fig. 4

fig. 4

9. REPLACING THE MECHANICAL FUSE

Warning !

All connection and maintenance operations must be carried out with the damper closed and the power supply discon-

nected.

• Check that the indicator on the control unit is set to CLOSE. If this is not the case, press the test button to close the

damper manually.

• Remove the plastic cover by loosening the central fastener screw (fig.2).

• Unscrew the 3 cross-head screws and remove the release mechanism from the plate (fig.3).

• Replace the fuse by squeezing the spring and hooking it onto the two protruding pins (fig.4).