BC300EN Broilchef Natural Gas Grill

Owner’s Manual

9

Assembly Instructions

Remove all contents from the carton packaging. Make sure all parts are present before attempting assembly.

Once the grill is fully assembled, go back and check to make certain all the bolts are secure. Tighten again

using the screwdriver and wrench provided if necessary. Estimated Assembly Time: 50 minutes.

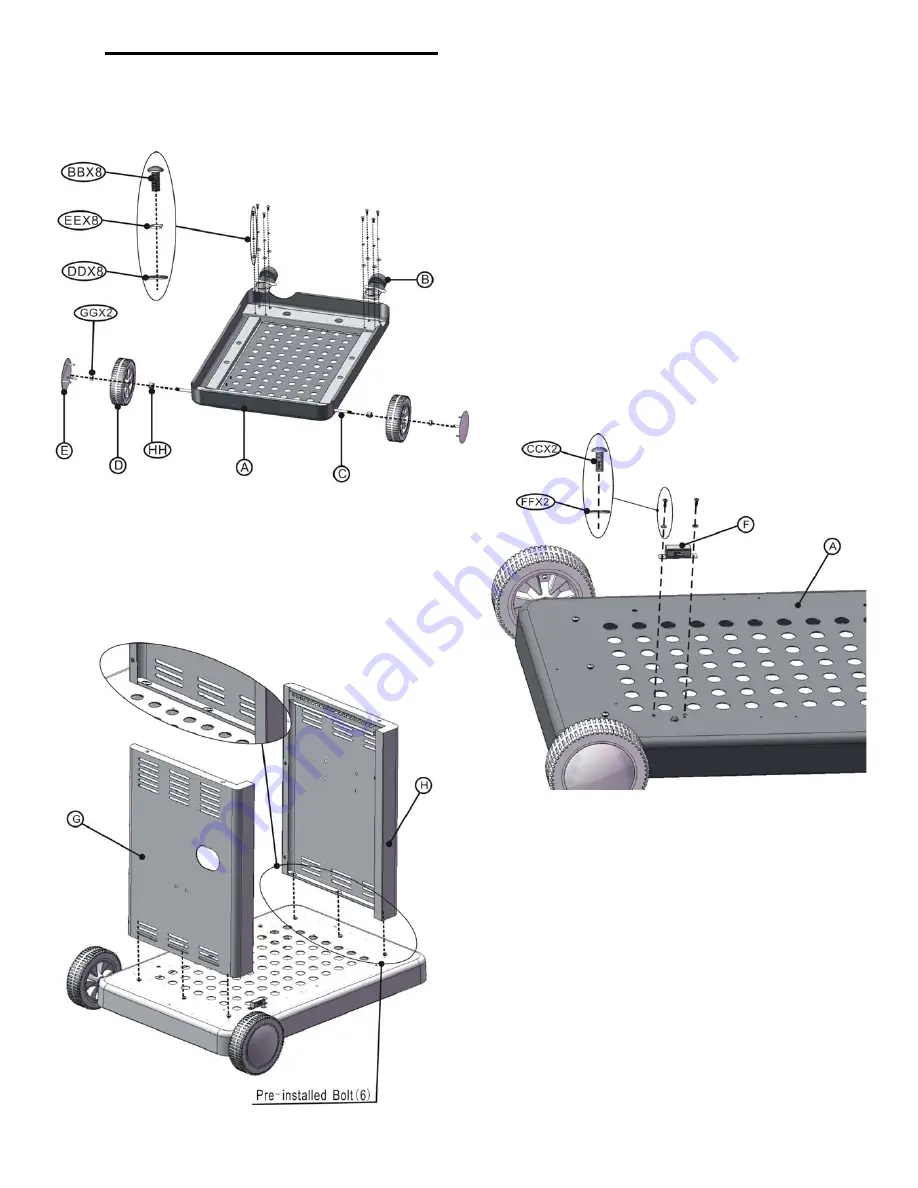

Step 1 (Swivel locking caster and wheel assembly)

Note: Before beginning assembly, make certain the two swivel

locking casters (B) are locked.

a) Align the two holes on swivel locking caster (B) with the two

holes on the bottom panel (A).

b) Insert one bolt (BB), one spring washer (EE) and one flat

washer (DD) into each pre-drilled holes and tighten all the

bolts using the screwdriver provided.

c) Insert the axle (C) into the hole in the bottom panel (A)

d) Put one spacer (HH) on each end of the axle.

e) Put one wheel (D) on each end of the axle.

NOTE: the protruding side of each wheel must face the

bottom panel.

f)

Screwing one lock nut (GG) on end of the axle using the

wrench provided.

g) Cover the wheel cap (E) on the wheel.

h) Repeat the procedure with the front wheel.

Step 2 (Magnet door latch assembly)

a) Align the two holes on the magnet door latch (F) with the two

holes on the bottom panel (A).

b) Insert one bolt (CC) and one spring washer (FF) into each

pre-drilled holes. Tighten bolts using the screwdriver provided.

Step 3 (Side panels assembly)

a) Loosen the three pre-installed bolts on the bottom panel (A) and

allow 1/4 bolt’s length to extend from bottom panel.

b) Align the holes on the bottom side of left panel (G) with the bolts

extended from the bottom panel.

c) Push back the left panel until it locks into place and tighten the

bolts by hand.

d) Repeat the procedure for the assembly of right panel (H) and

bottom panel.

e) Go back and tighten all bolts using the screwdriver provided.