Bronkhorst®

Instruction Manual EL-FLOW® Prestige

9.17.084N

16

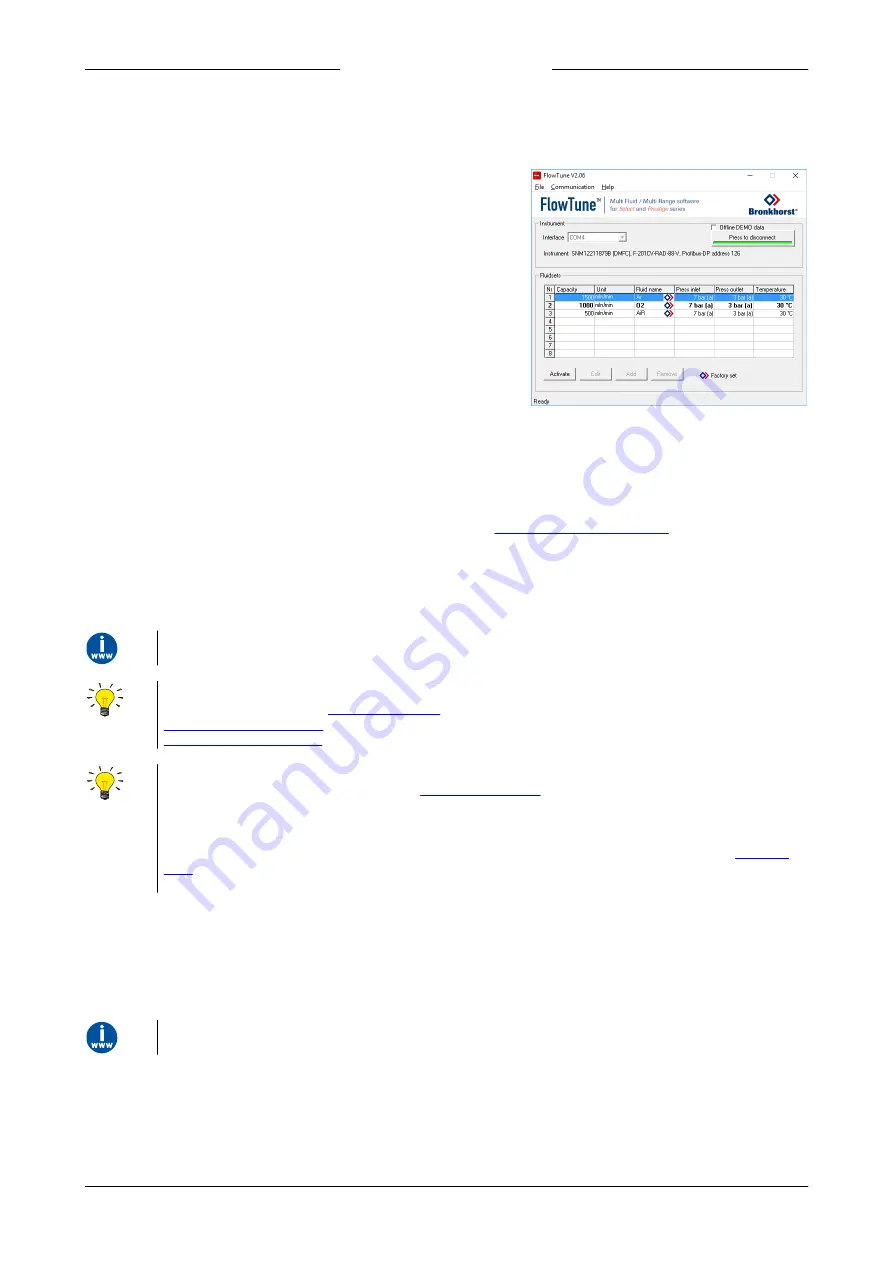

MFMR enabled instruments are calibrated ex factory for a number of standard measuring ranges, which can be configured

for use with different fluids. Defining fluids and ranges and selecting the active fluid can be done via RS-232 with

FlowTune™.

FlowTune™ provides the following key functionality:

·

Definition and storage of up to eight different fluids in the instrument

·

Storing fluid properties for any gas

·

Changing inlet- and/or outlet pressure based on actual process

conditions

·

Re-ranging the full scale (FS) flow rate within the instrument's

supported flow range

·

Changing control speed per fluid set for faster or slower (smoother)

flow control

MFMR functionality is available for the full temperature and pressure range of the instrument. FlowTune™ checks the

changes for the following limitations:

·

Rangeability of the flow sensor for the selected fluid

·

Rangeability of the control valve for the selected fluid

·

Accuracy indication for the given flow range

·

Compatibility of selected gases with the used sealing materials (see

Sealing material compatibility

·

Limitations to the operating conditions

After all limitation checks are passed, the entered properties are stored in the instrument, including the required controller

settings. When switching to another fluid set, controller settings are automatically adjusted to the new process conditions,

so there is no need to change PID controller settings manually.

The FlowTune™ software and the associated documentation can be downloaded from the product pages on the Bronkhorst

website:

Note regarding instruments with active pressure compensation:

For

EL-FLOW® Prestige PI

(see

) instruments and and instruments with

I/O option H1P

enabled (see

Customized I/O options (pin 5)

) the inlet pressure entered in FlowTune is used only for flow range/capacity calculations (see

).

To connect with FlowTune™, use RS232 communication via the 9-pin D-sub connector. In case a connection cannot be

established, use the power-up functionality of the

to switch to configuration mode and enable

RS232 communication.

After configuring the required parameters, remember to return the instrument to the original communication mode.

It is advised to use FlowTune™ only in a non-operational environment. FlowTune™ will force the instrument to

as soon as the connection is made. Be sure to close communication between FlowTune™ and the instrument

properly, to restore the normal operating mode.

Using custom fluids or fluid properties

With FlowTune™ fixed fluid properties for any gas or mixture can be stored in the instrument (density, heat capacity,

thermal conductivity and dynamic viscosity). Although custom fluid data can be used, Bronkhorst advises to use the

FLUIDAT® on the Net website for calculation of fluid properties at the actual process conditions. FLUIDAT® is a collection of

routines to calculate physical properties of gases and liquids. These routines are made available at the FLUIDAT® on the Net

website.

FLUIDAT® on the Net can be accessed on

www.fluidat.com

. You can try out FLUIDAT® on the Net with a limited number

of fluids. Free registration on the FLUIDAT® website gives access to all available fluids and functionality.