Bronkhorst®

Instruction Manual FLEXI-FLOW™ Compact

9.17.158A

11

2

Installation

2.1

Product specifications

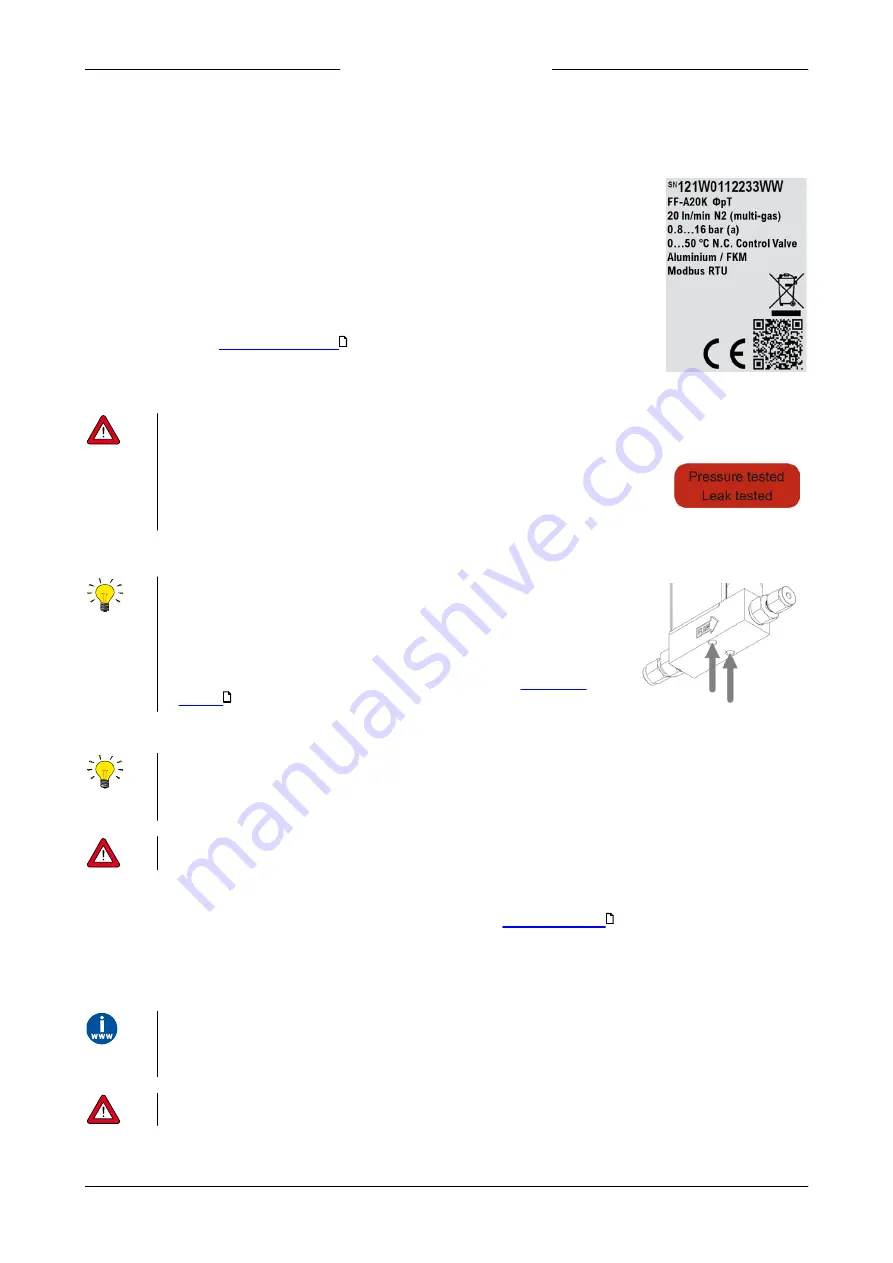

Before installing the FLEXI-FLOW™, check that the functional and technical properties of the

product match your requirements (the image on the right is an example; it does not necessarily

reflect the actual specifications of your instrument).

If you have a question about the product or if you find the product does not meet the

specifications as ordered, do not hesitate to contact your Bronkhorst representative (see the first

pages of this document). To enable us to help you quickly and effectively, have the serial number

ready whenever seeking contact with your Bronkhorst representative about a specific item. The

serial number is the key to the original purchase order and can be found on the serial number

label, in the instrument properties in FlowSuite and by reading the according digital parameter

(see parameter section

).

2.1.1

Pressure rating

At the factory the FLEXI-FLOW™ has been pressure tested and tested with helium for outboard leakage. The test pressure

includes a safety factor, so that it is always higher than the specified maximum operating pressure (pressure rating).

·

The test pressure is specified with a red label; if this label is missing, the device must not be

used and should be returned to the factory.

·

Before installation, make sure that the pressure rating is within the limits of the normal

process conditions of your application.

2.2

Mounting

For optimal performance, observe the following guidelines:

·

Avoid installation in close proximity of mechanical vibration and/or heat sources.

·

Use the equipment in an environment with a stable ambient pressure and

temperature.

·

For stable fixation to a rigid and stable surface or construction, use the threaded

mounting holes in the bottom of the instrument base. Consult the

for the exact size and locations.

2.2.1

Piping requirements

·

For reliable performance, make sure the fluid stream is uncontaminated. If necessary, use an inlet filter to ensure a

particle free media stream. Select a filter with a maximum pore size of 20 µm and a surface area that minimizes the

pressure drop.

·

If back flow could occur, the use of a check valve is also recommended.

Use piping or tubing that is suitable for the operating conditions of the application (media, maximum temperature,

maximum operating pressure).

2.2.2

Fluid connection

·

Connect the FLEXI-FLOW™ to the fluid system in accordance with the

.

·

Tighten fluid connections according to the instructions of the manufacturer of the fittings. The use of Swagelok® RS-type

stainless steel adapters is recommended.

·

Make sure connector sizes match; do not mix metric (mm) and imperial (inch) sizes.

·

Make sure all connectors and tubing are free from dirt and debris.

Instructions for connecting and disconnecting Swagelok® fittings can be found in the Installer's Pocket Guide for Swagelok®

Tube Fittings (doc. no MS-13-151)

This document can be downloaded from the Swagelok® website (

Do not apply fluid pressure until all required fluid connections and electrical connections have been made.

32

9

7