Bronkhorst®

Instruction Manual IQ+FLOW® Series Digital Mass Flow / Pressure Controllers for Gases

9.17.045V

14

3.3

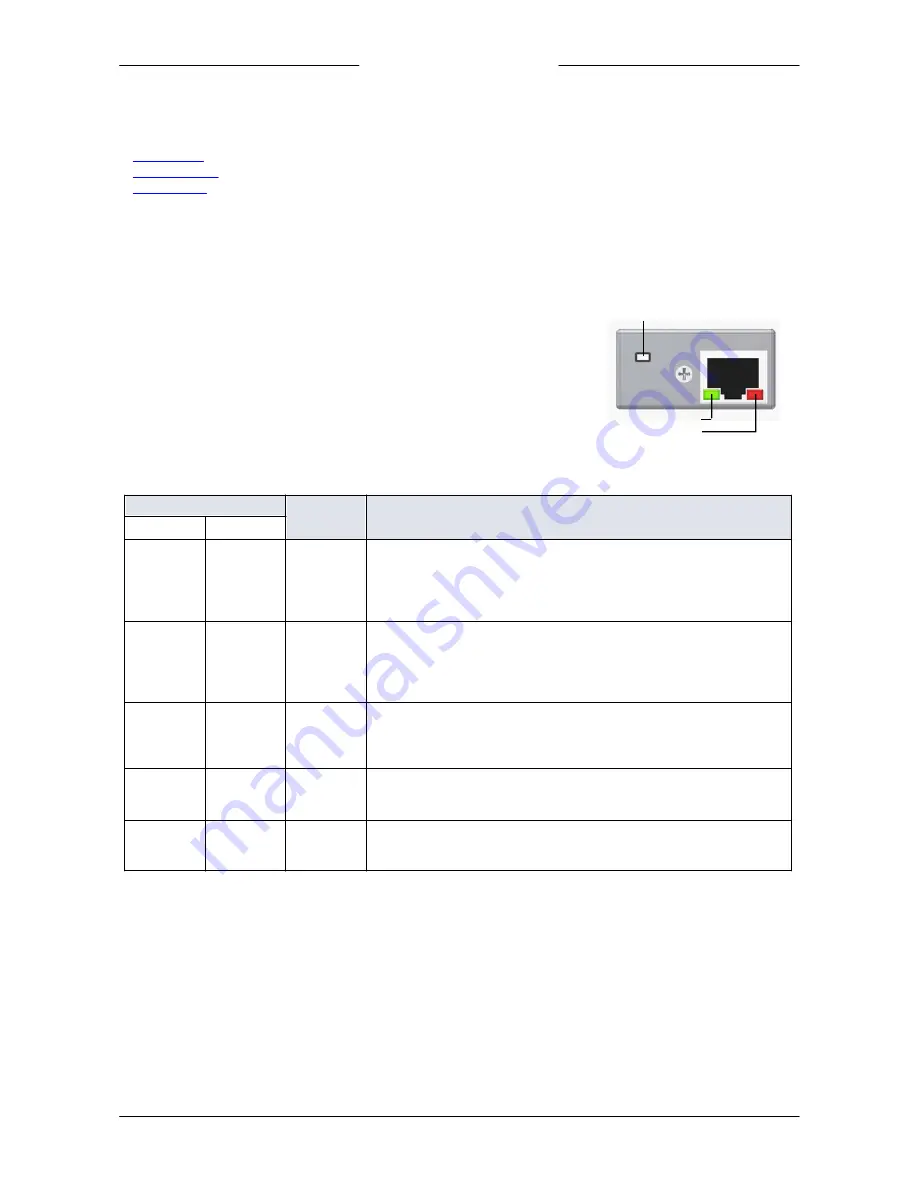

Manual interface: micro-switch, LEDs and rotary switches

In this section the manual instrument interfaces are described:

·

Micro-switch

·

Indication LEDs

·

Rotary switch

3.3.1

Micro-switch operation (single-channel versions only)

By means of manual operation of the micro push-button switch some important actions for the instrument can be selected

or started. These options are available in both analog and digital operation mode.

These functions are:

·

Reset alarm

·

Reset instrument (firmware program reset)

·

Auto-zeroing

·

Restore factory settings (in case of accidently changing of the settings)

Using digital RS232 or RS485 operation it is also possible to set:

·

Bus-address (only required for RS485)

·

Baudrate

·

Change control mode

Multi-functional switch

Status LED

Error/Warning LED

The tables below describe the micro-switch functions that can be started in normal operation mode and during power-up:

LEDs

Time

Pushed

Indication

Green

Red

Off

Off

0 – 1 sec.

No action

. Pressing a switch shortly by accident will not start any

unwanted reaction of instrument.

Pressing the switch 3x briefly with intervals of max. 1 sec. forces the

instrument to indicate its bus-address and baud rate. Check

section 3.5

for

more details.

Off

Off

1 – 4 sec.

In case of min/max alarm or counter batch reached:

Reset alarm

(only if

reset by keyboard has been enabled)

For FLOW-BUS only: if the node address is occupied, this function will

install a free node-address

on FLOW-BUS.

Off

On

4 – 8 sec.

Reset instrument

Instrument program will be restarted and all warning and error messages

will be cleared. During start-up the instrument will perform a (new) self-

test.

On

Off

8 – 12 sec.

Auto-zero

Instrument will be re-adjusted for measurement of zero-flow (not for

pressure meter/controller). See

section 2.10

.

On

On

12 – 16 sec.

Prepare instrument for

FLASH mode

for firmware update.

Instrument shuts down and both LEDs turn off.

At next power-up instrument will be active again.

LED indications using micro-switch at normal operation mode of an instrument