Bronkhorst®

Instruction Manual IQ+FLOW® Series Digital Mass Flow / Pressure Controllers for Gases

9.17.045V

9

2.4

Install system

For IQ+FLOW® installation in an upright position is preferred. When using an

IQ+FLOW® gas flow instrument in a position with upward or downward flow,

adjusting the zero point

prior to first use is recommended. Avoid installation in close

proximity of mechanic vibration and/or heat sources. The housing of the instrument

has ingress protection class IP40, which means that the instrument is suitable for

indoor (dry) applications, like laboratories or machine enclosures.

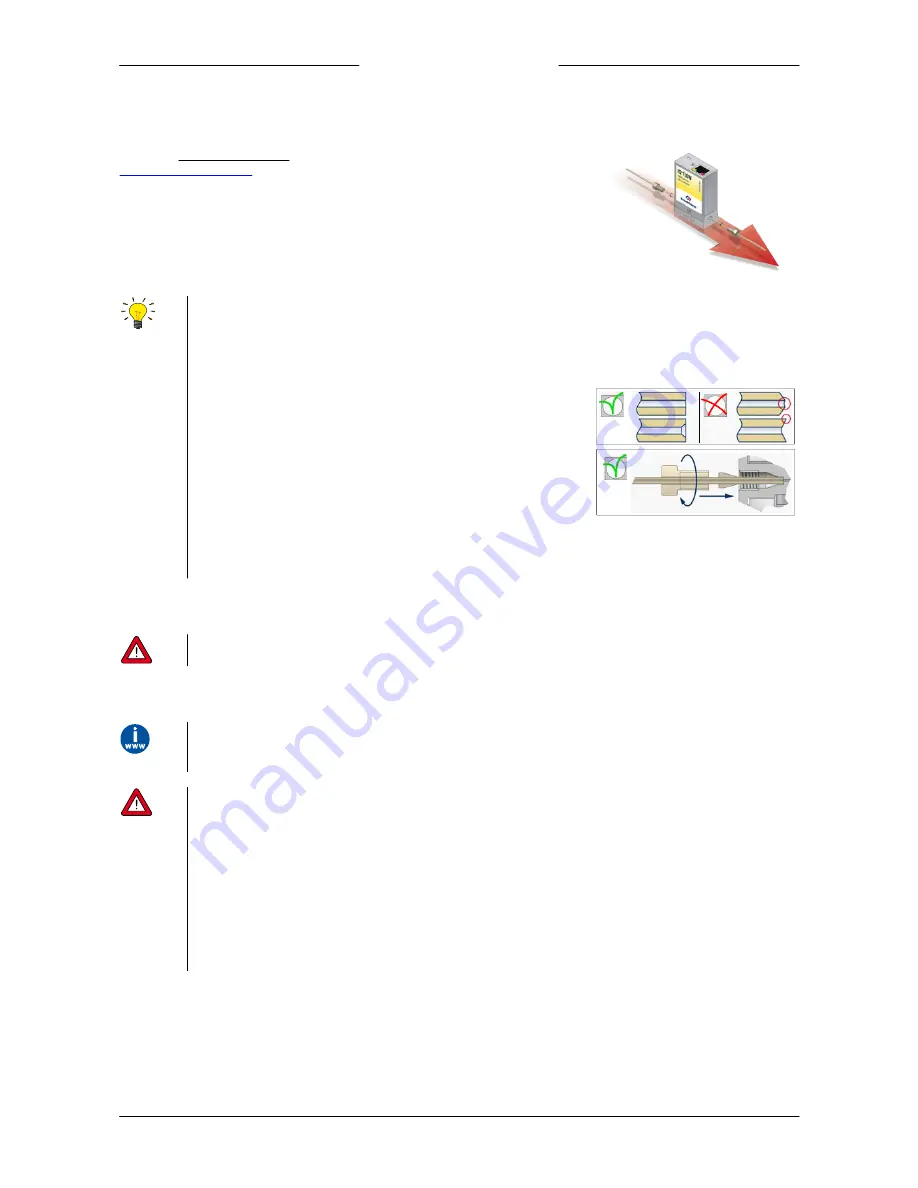

Install the IQ+FLOW® instrument in the line, in accordance with the direction of the

FLOW arrow on the base of the instrument. If applicable follow the guidelines of the

supplier of the fittings. Special types of fittings are available on request.

Compression type fittings

For leak tight installation of compression type fittings make sure that the tube is inserted up to the shoulder in the fitting

body and that no dirt or dust is present on tube, ferrules or fittings. Tighten the nut finger tight; while holding the

instrument, then tighten the nut one turn.

10-32 UNF fittings

Tighten the 10-32 UNF fittings according to the instructions of the supplier of the

fittings.

Only use 1/16” tubing with a straight and clean cut without burrs to ensure leak

tightness. Preferably deburr the tubing prior to installation. A new ferrule

connection must be made for each new adapter to ensure leak-tightness and

minimum dead volume, due to variances in the adapter dimensions.

Mounting downported instruments

For downported instruments make sure that the seals are present at the bottom, that the surfaces are undamaged and that

they are dry and free from dirt or dust.

2.5

Leak check

Check the fluidic system for leaks before applying pressure, especially when using hazardous media (e.g. toxic or

flammable).

2.6

Electrical connection

Electrical connections must be made with a standard cable, according to the IQ

+

FLOW® hook-up diagram. Several hook-

up examples and standard cables can be found in

section 3

.

IQ+FLOW® instruments are powered with +15…+24 Vdc.

The device contains electronic components that are susceptible to damage by

electrostatic discharge

. Proper handling

procedures must be followed during installation, (dis)connecting and removing the electronics.

The devices described in this manual carry the CE-mark and are

compliant with the concerning EMC requirements

.

However, compliance with the EMC requirements is not possible without the use of proper cables and connector/gland

assemblies. Bronkhorst recommends the use of their standard cables. These cables have the right connectors and if loose

ends are used, these are marked to help prevent wrong connection. When using other cables, cable wire diameters should

be sufficient to carry the supply current, and voltage loss must be kept as low as possible. When in doubt, contact your local

Bronkhorst representative.

When connecting products to other devices, be sure that the integrity of the shielding is not affected;

always use shielded

cabling for signals and communication and do not use unshielded wire terminals.