9.17.093

2

SCOPE OF THIS GUIDE

mini CORI-FLOW™

instruments are highly accurate instruments for measuring and controlling the mass flow rate of liquids and/or

gases, independent of fluid properties. These smart Coriolis instruments offer multiple process values as input- or output

parameters. Many parameters can be read and/or changed using analog or digital interfaces. Output parameters are: mass flow,

density, temperature, totalized mass flow, alarms. Input parameters are: setpoint (desired mass flow rate for controllers), reset

alarm/counter.

This manual will help you start-up your

mini CORI-FLOW™

ML120

in only 10 steps and contains:

1.

Instrument functional properties

2.

Check safety properties

3.

Check piping

4.

Mount/install instrument

5.

Leak check

6.

Electrical connection

7.

Operation

8.

Multi-functional switch

9.

Purging

10.

Zeroing

mini CORI-FLOW™ ML120

instruments have modular instruction manuals consisting of:

- Instruction manual

mini CORI-FLOW™ ML120

(document nr. 9.17.097)

Info about e.g. : sensors, valves, liquid dosing systems, maintenance, tooling, calibration, Kv-value calculation, troubleshooting.

- Hookup diagram

mini CORI-FLOW™

and

CORI-FLOW™

(general)

(document nr. 9.16.132)

- FlowPlot Manual

(document nr. 9.17.030)

Depending on optional fieldbus interface:

Fieldbus/interface description

Manual

Hookup diagram

- RS232 Interface with FLOW-BUS protocol

9.17.027

9.16.132

- FLOW-BUS Interface

9.17.024

9.16.133

- PROFIBUS DP Interface

9.17.025

9.16.134

- DeviceNet™ Interface

9.17.026

9.16.135

- Modbus interface

9.17.035

9.16.136

- EtherCAT interface

9.17.063

9.16.137

- PROFINET

9.17.095

9.16.146

i

www

These documents can be downloaded from the website:

http://www.bronkhorst.com/qrcoriolis

or can be sent by e-mail on request.

Notes for temperature considerations

After having used the

mini CORI-FLOW™ ML120

the first time at low temperature tighten the fluid adapter screws again in

order to prevent any leakage! Please note: if you do not tighten, the leaking adapter / fitting can cause damage! After the

first shrinking and tightening of the screws, no further precaution is necessary.

Note:

The maximum allowed temperature in the housing of the

mini CORI-FLOW™ ML120

is 70 °C. To check this, the

internal temperature sensor can be used. Temperature can be readout digitally via FLOW-DDE/E-8000 (FlowDDE par. 142) or

BRIGHT (local readout/control module). Make sure the temperature value readout here (=actual temperature in housing)

will not exceed 70 °C.

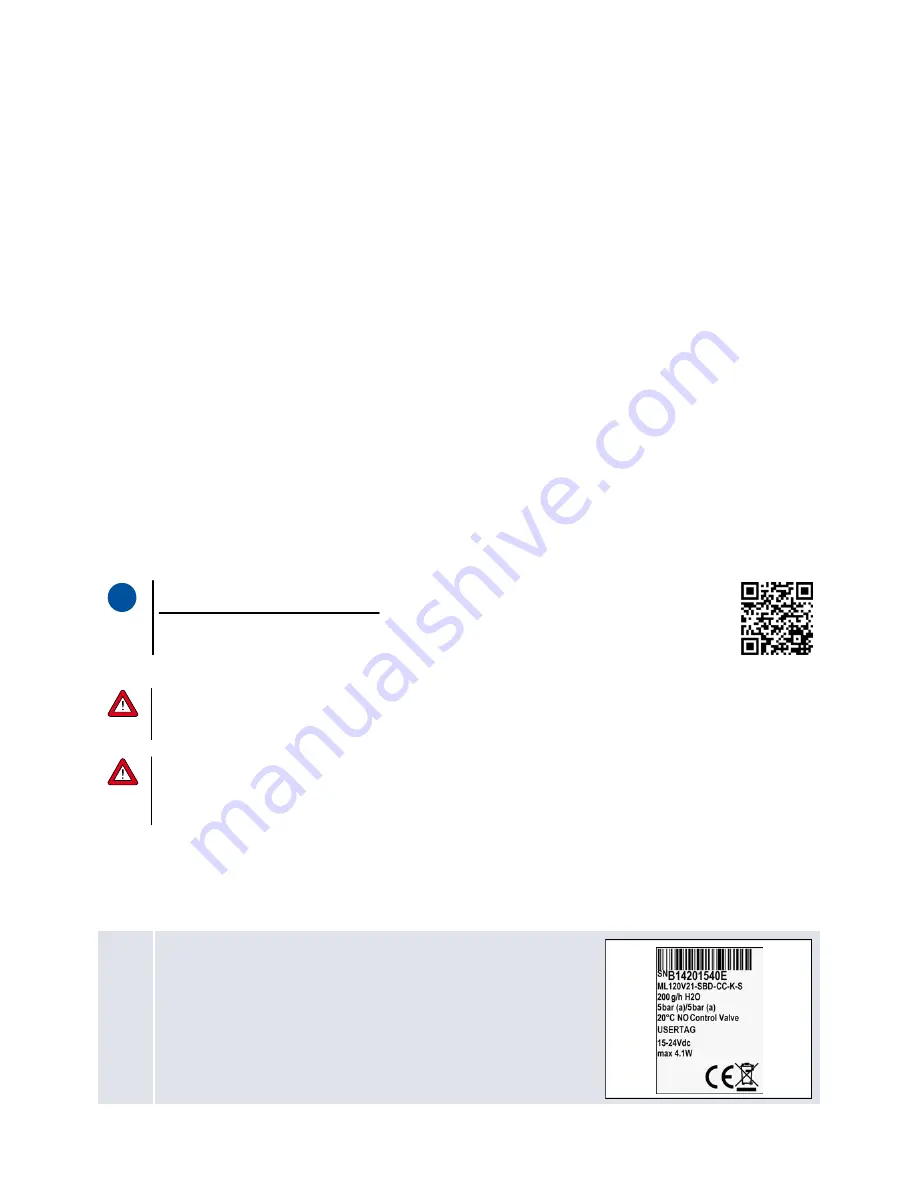

STARTING-UP

1

Check mini CORI-FLOW™ ML120 functional properties

Before installing your Mass Flow Meter/Controller it is important to

read the attached label and check:

·

Flow rate

·

Fluid to be measured

·

Up- and downstream pressures

·

Input/output signal

·

Temperature

·

Valve type

(if controller)