© Bronkhorst High-Tech B.V.

3

2

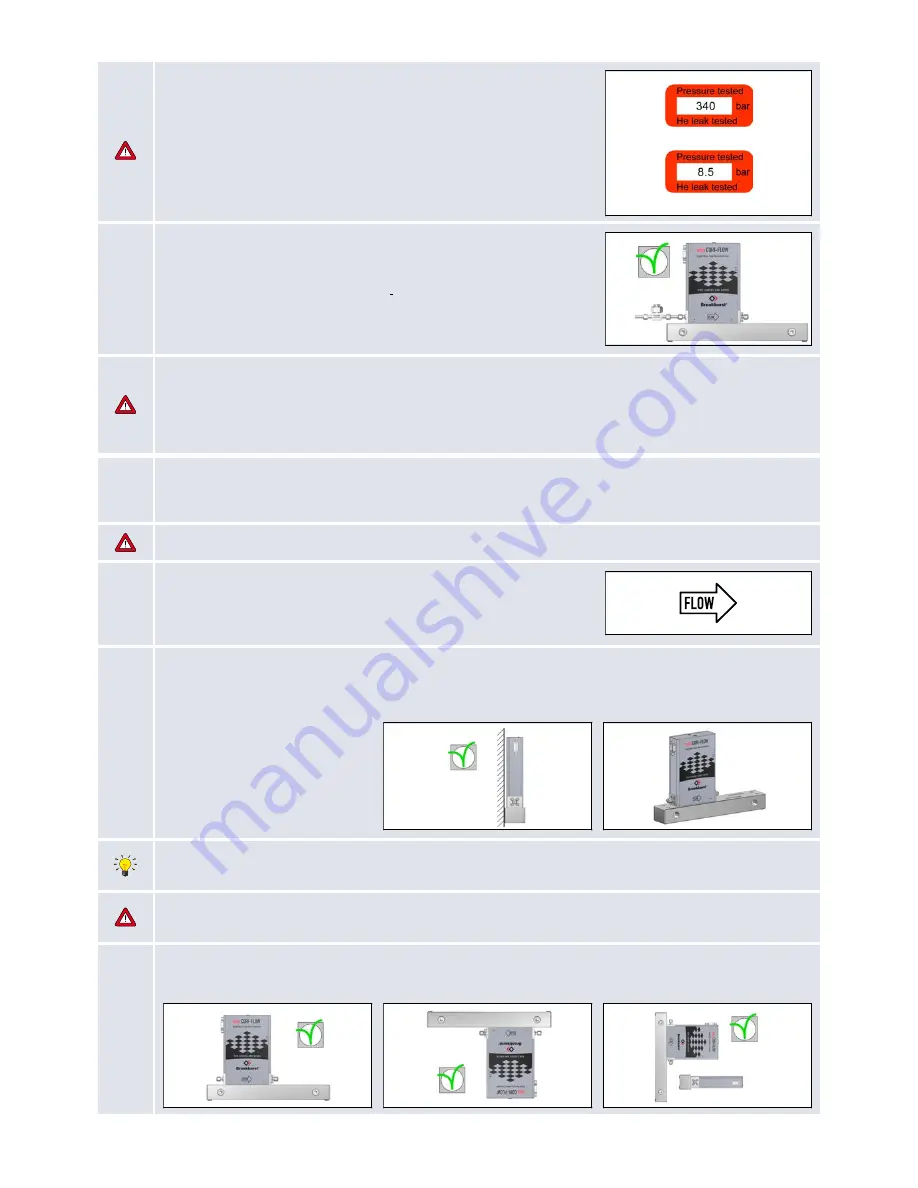

Check test-pressure

The tested pressure is stated on the instrument with a red-colored sticker.

Before installation, make sure that the test pressure is in accordance with

normal safety factors for your application. If there is no Pressure Testing

Sticker on the device or if the test pressure is incorrect, the instrument

should

not

be mounted in the process line and be returned to the factory.

NOTE! Tested pressure is higher than the (normal) operating pressure.

Mass Flow Meter

Mass Flow Controller

3

Check if system piping is clean

For reliable measurement always make sure the fluid stream is clean.

Use filters to assure a particle free liquid stream or a moisture- and

oil-free gas stream. Recommended pore size: 0,5...25 µm. If back flow

can occur, a downstream filter and a check valve are recommended too.

For high flow rates select a suitable filter size, to avoid too high

pressure drop or cavitation.

Warning!

During the manufacturing process, the instruments have been tested with water. Despite the fact that the

instruments have been purged thoroughly afterwards, we cannot guarantee that the delivered instruments are

absolutely free from water droplets. Bronkhorst strongly recommends performing an additional, adequate drying

procedure for those applications where remaining water particles may cause undesired reactions such as corrosion.

4.1

Mount/install instrument properly

Install the

mini CORI-FLOW™ ML120

Meter/Controller in the line and tighten the fittings according to the

instructions of the supplier of the fittings.

During operation avoid external vibrations and shocks.

4.2

Flow direction

Install the

mini CORI-FLOW™ ML120

in accordance with the direction of

the FLOW arrow. The arrow for flow direction is indicated on the

mini CORI-FLOW™ ML120

, between process fittings.

4.3

Base mounting

Mount the

mini CORI-FLOW™ ML120

instrument, with screws in the body, to a rigid, stiff base body or heavy mass,

such as a wall, heavy rig or stable construction. This is essential to achieve optimal accuracy with the

mini CORI-

FLOW™ ML120

instrument.

By default the

mini CORI-FLOW™ M12, M13, M14

and

ML-120

will be delivered on a special mounting block for

achieving optimal accuracy.This mounting block has a mass and stiffness precisely tuned for the specific model.

Removing the mounting block will cause inaccuracy unless the instrument is firmly mounted on a vibration free, stiff

and rugged surface. Mounting on plates of machine cabinets is not recommended.

4.4

Mounting position general

For gas and liquid

mini CORI-FLOW™ ML120

meters can be mounted in any position for a proper measurement.