9.17.093

4

4.5

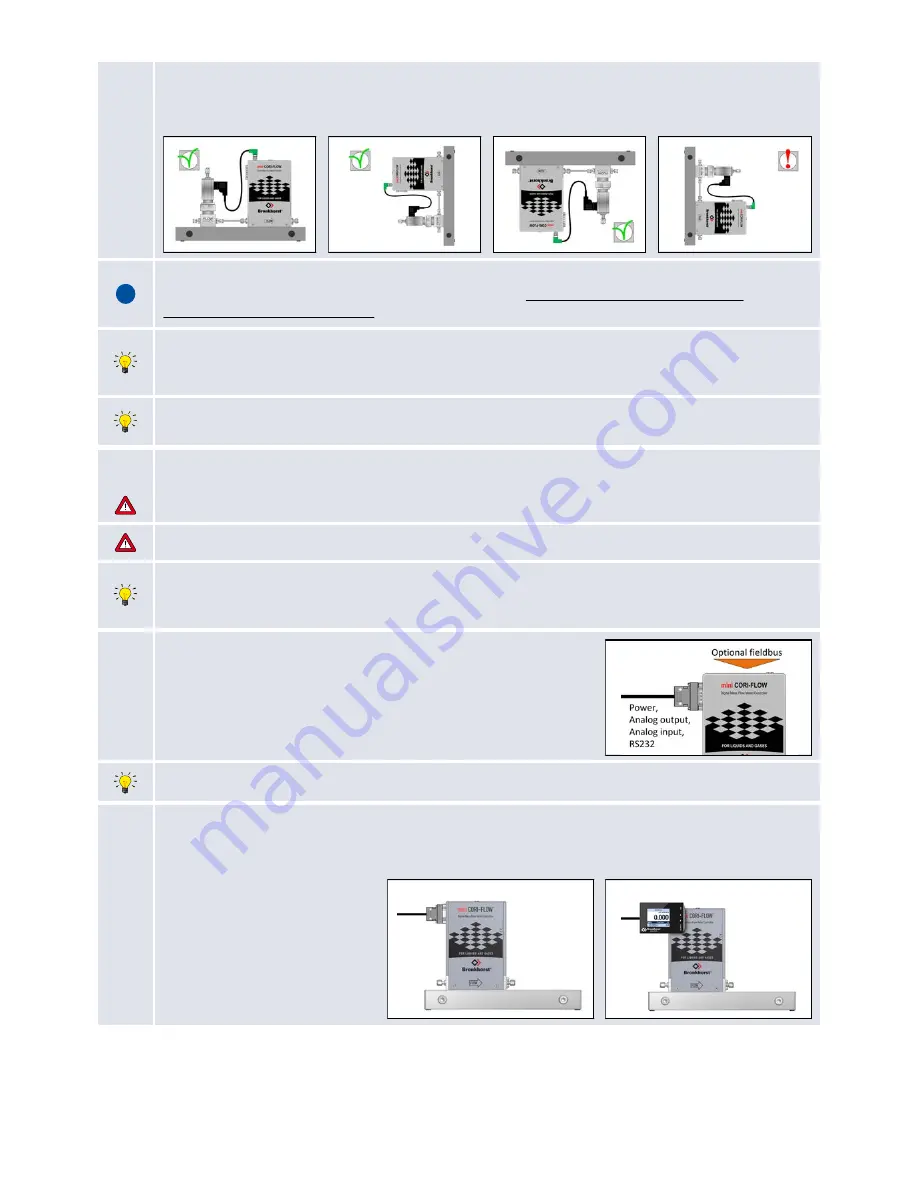

Mounting position when using mini CORI-FLOW™ ML120 with external valve with purge connector

For the

mini CORI-FLOW™ ML 120

series instruments with external liquid valve with a purge connector, the

mounting position can be critical for a good quality of de-gassing.

i

www

Please consult the Instruction Manual for additional information on mounting the mini CORI-FLOW instruments. This

document can be found in the download section of our website:

www.bronkhorst-cori-tech.com/en/

downloads/instruction_manuals/

Liquid purging

In order to remove gas bubbles during start-up, flushing with relatively high flow rate of liquid for a few seconds is

recommended.

Leak tightness

Verification of leaks is required prior starting up of the process.

5

Leak check

Check the system for leaks before applying (fluid) pressure. Especially if toxic, explosive or other dangerous fluids

are used!

Avoid condensation due to cold liquids/gases at high humidity environments.

Liquid tight is not the same as gas tight

Please note that connections which are tight for liquid, could still be untight for gas. This can result in Air enclosure

in the liquid, e.g. when using external valves, which might lead to errors in measurement.

6

Electrical connection

Electrical connections must be made with a standard cable or according to

the

mini CORI-FLOW™ ML120

hook-up diagram.

mini CORI-FLOW™ ML120

instruments have a IP40 ingress protection rating.

7.1

Analog/Local operation

Connect the

mini CORI-FLOW™ ML120

to the power supply/readout unit with the D9 cable at the Sub D9

connector. The two examples below have the following electrical properties:

Power

Analog

output

Analog input

(controller)

: +15...+24 Vdc

: 0...5 Vdc / 0...10 Vdc

0...20 mA / 4...20 mA

: 0...5 Vdc / 0...10 Vdc

0...20 mA / 4...20 mA

Example 1

Example 2