Bronkhorst®

Instruction Manual mini CORI-FLOW ML120

9.17.097G

55

The following digital parameters are involved in the filtering and minimum capacity settings:

Name

Process/

Parameter

Modbus

register no

Value

Purpose/Remarks

Dynamic Display Factor

(56)

117/1

62729…

62730

1

disable filter

Static Display Factor (57)

117/2

62737…

62738

1

disable filter

Sensor Exponential

Smoothing Filter (74)

117/4

62753…

62754

1

disable filter

Capacity Minimum (247)

1/27

33241…

33242

as required typical value (for mini CORI-FLOW ML120): 5 g/h

5.3.5

Proportional control settings

Adjusting flow range

A proportional control valve enables re-scaling of the controllable flow range, making it possible to dose with a lower flow.

This increases the running time of the batch (especially in the linear phase; see

Dosing principle - Dosing principle

), but also

provides higher accuracy. To minimize batch size overshoot, the flow can be reduced further when nearing the configured

batch size (control gain phase).

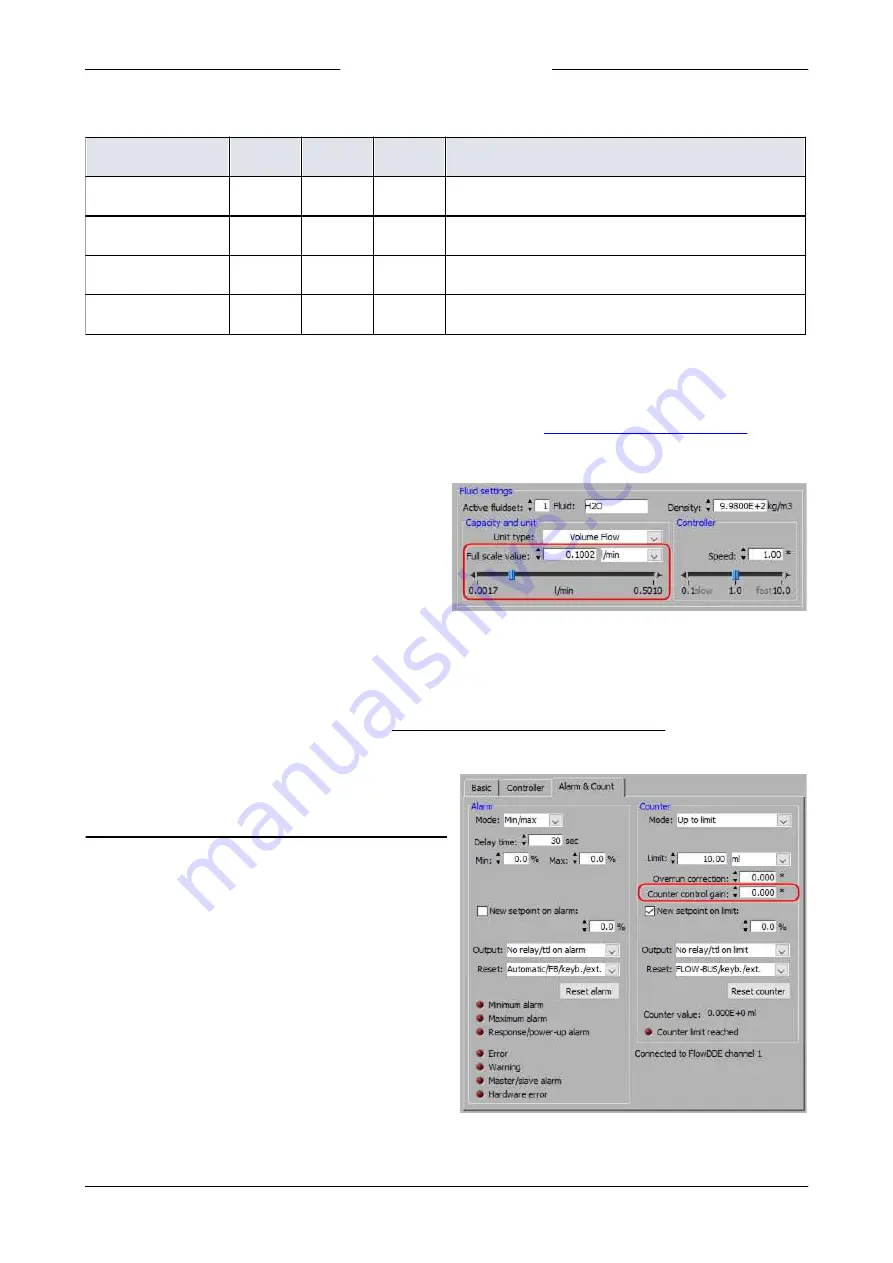

To change the maximum capacity in FlowPlot, return to the

Basic

tab of the

Instrument Settings

function and edit the

Full

scale

value. In the plotting area of the main screen, this value

is translated to 100%.

The starting point of the control gain phase is determined by the value of

Counter control gain

. From the start of the

controller gain phase, the valve is closed gradually (or the pump speed lowered), until the configured batch size is reached.

The required value can be calculated with the following formula:

delivered

batch

of

Percentage

100%

100%

gain

control

Counter

-

=

The table below shows some example values:

Percentage

delivered

Counter control gain

0%

1

50%

2

75%

4

longer dosing time,

80%

5

less overshoot

90%

10 (default)

•

95%

20

shorter dosing time,

98%

50

more overshoot

99%

100

If the value is set to 0, control gain is disabled. Essentially, this

turns proportional control into on/off control.

In FlowPlot, the input location of

Counter control gain

can be

found on the

Alarm & Count

tab of the

Instrument Settings

.