Bronkhorst®

Instruction Manual mini CORI-FLOW ML120

9.17.097G

57

The following digital parameters are involved in optimizing proportional control:

Name

Process/

Parameter

Modbus

register no

Value

Purpose/Remarks

Valve Open (190)

114/24

62145…

62146

as required set minimum current/voltage required to open the valve

Setpoint Slope (10)

1/2

35

0

adjustment time when changing setpoint from 0% to 100% (range

corresponds with 0…3000 seconds)

PID-Kp (167)

114/21

62121…

62122

10

controller proportional action

(increase to speed up controller, decrease to slow down)

PID-Ti (168)

114/22

62129…

62130

0.1

controller integral action

(decrease to speed up controller, increase to slow down)

PID-Td (169)

114/23

62137…

62138

0

controller derivative action (prevents setpoint overshoot)

For more information about the PID controller, see

Digital parameters - Controller

in this manual or the FlowPlot manual

(document 9.17.030).

5.3.6

On/off control settings

Minimizing valve temperature

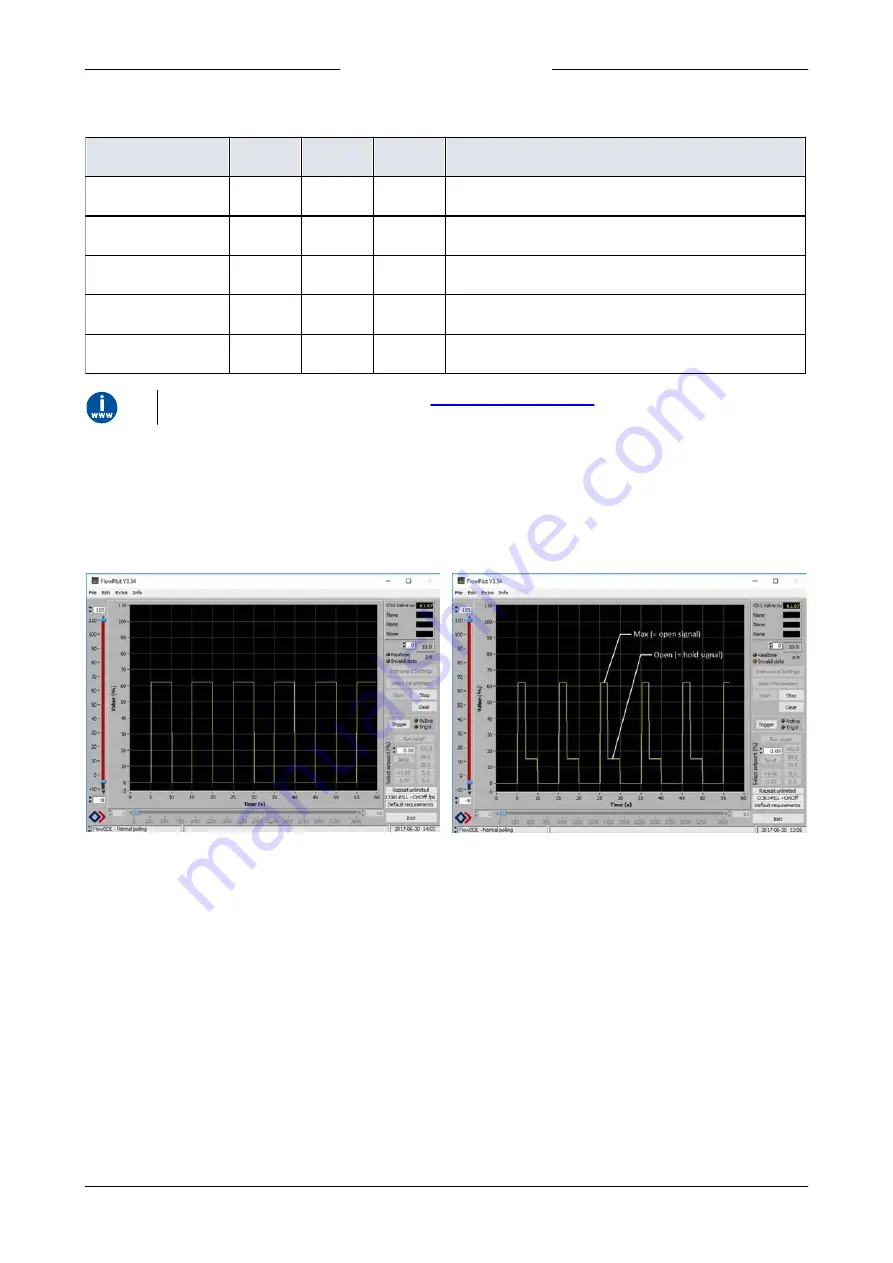

When working with fluids with a low boiling/evaporation point, it can be useful to limit the power dissipation by a shut-off

valve, in order to minimize the temperature rise caused by valve actuation. A shut-off valve needs a stronger signal to open

it than to keep it open (hold signal). Once it is open, the signal can safely be set to a lower point, reducing power

dissipation by the valve coil (thereby minimizing temperature rise).

On/off control without hold signal

On/off control with hold signal