Bronkhorst®

Instruction Manual mini CORI-FLOW ML120

9.17.097G

60

6

Troubleshooting and service

During operation, the LEDs can indicate errors and/or warnings. See

for an explanation of the possible LED

indications.

Error and warning information can also be found by connecting the instrument to FlowDDE and FlowPlot (see section

). FlowDDE puts all errors and warnings on the console screen; in FlowPlot, the Alarm & Count tab

(Instrument Settings) provides several specific alarm and counter indicators.

6.1

Restoring factory settings

In case changes to the instrument configuration leads to non-recoverable erroneous behavior, the instrument can be reset

to the pre-configured factory settings. This can be done in FlowPlot (Instrument Settings > Restore Settings) or with the

multifunctional switch (see

).

Changes made to the network settings (bus address, baud rate, parity) will

not

be restored by a factory reset.

If digital communication with the instrument can not be re-established, see

mode, overrule the 9-pin D-sub communication settings and use the RS232 communication mode to re-establish

communication.

6.2

Common issues

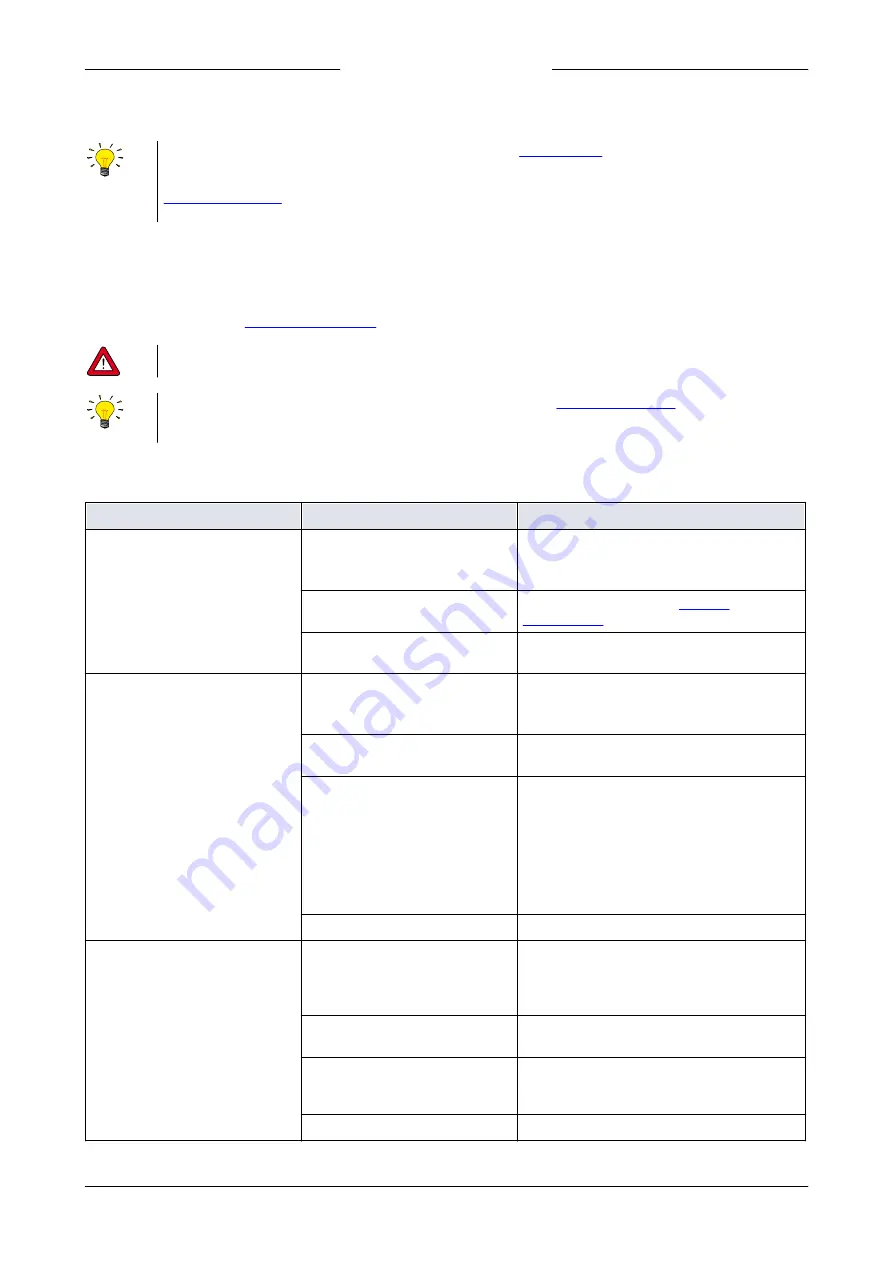

Symptom

Possible cause

Action

No fieldbus communication

No power supply

·

Check power supply

·

Check cable connection

·

Check cable hook-up

Invalid node address

Change node address (see

Other

Reset instrument and/or restart master. Contact

Bronkhorst if problem persists.

No output signal

No power supply

·

Check power supply

·

Check cable connection

·

Check cable hook-up

Inlet pressure or differential

pressure too low

Increase inlet pressure

Piping, filters and/or control valve

clogged or blocked

·

Clean system (flush with clean, dry air or a

non-aggressive cleaning liquid (e.g. ethanol

or isopropyl alcohol)

·

For external proportional control valves:

supply 0…15 Vdc and operational inlet

pressure to valve and slowly increase

voltage. If valve does not open, clean parts

and re-adjust valve

Sensor failure

Return equipment to factory

·

Control behavior unstable

·

Red LED flashes irregularly

Measurement disturbed by

mechanical vibration

·

If possible, avoid installation in close

proximity of mechanical vibration

·

Reduce sensitivity to vibrations by using a

mass block, dampeners, and flexible tubing

Inlet pressure unstable

Eliminate pressure fluctuations, e.g. by

installing a pressure regulator

Gas accumulation in tubing

Flush the system to remove gas

Tip: use frequency or density signal to detect

presence of gas bubbles

Wrong controller settings

Adjust settings (e.g. with FlowPlot)