Polycold Cryochiller

Troubleshooting

Installation and Operation Manual

HMI and Observed Errors

Brooks Automation

214072 Revision B

10-7

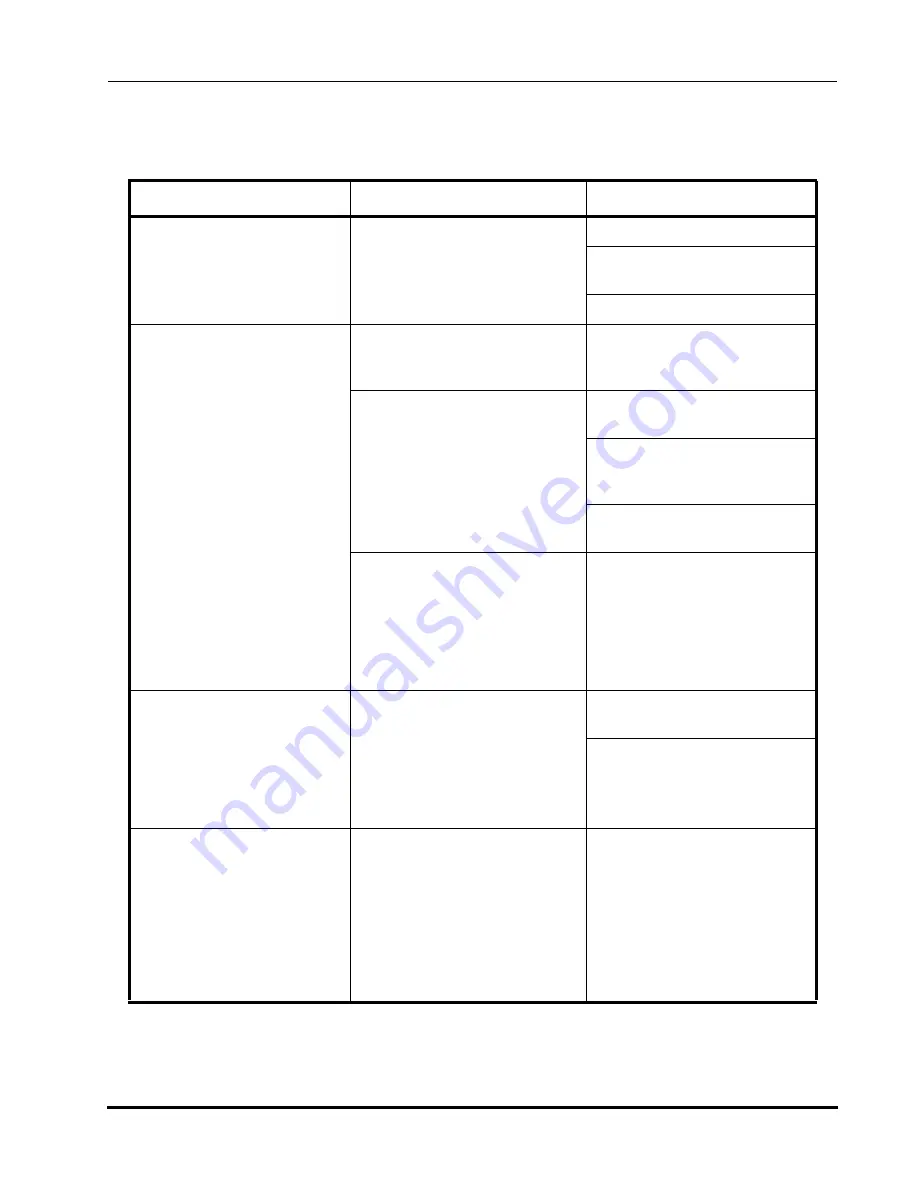

Temperature Related Troubleshooting

Problem / HMI Display

Possible Cause

Corrective Action

FREEZOUT PREVENTION

Fault LED not lit

Freeze out prevention sensor is

experiencing a temperature

colder than expected.

Check refrigerant

Check freezeout prevention

valve and thermocouple

Contact authorized service

C1 CUST TC FAILED

C2 CUST TC FAILED

Fault LED is Amber

Thermocouple not proper type

Verify that a type T (copper -

constantan thermocouple sen-

sor is being used.

Thermocouple not properly

installed

Check installed polarity of cus-

tomer installed thermocouple

Check TC terminal connection

tightness Torque

Spec is 0.34 N-m (3 lb-in)

Check thermal bonding of sen-

sor to tube.

Thermocouple junction not prop-

erly fabricated

Check TC junction is commer-

cially prepared junction

OR

TC junction is soldered or

welded

TC Junction must NOT be just

twisted wires

HIGH DISCHRG TEMP

REFRIGERANT LEAK

CHECK BALANCE PRES-

SURE

Fault LED Amber

Compressor discharge tempera-

ture is too high

Check cooling water flow

Contact authorized service

REF LQD LINE TEMP

Fault LED is Amber

Cooling water flow and / or

temperature are outside of

acceptable limits.

The system turns off due to

excessively low cooling water

temperature, excessively high

cooling water temperature or

insufficient flow.

Check your temperature and

flow to ensure it is within

acceptable limits.