Polycold Cryochiller

Installation

Installation and Operation Manual

Check the Refrigerant Line and Cryosurface for Leaks

Brooks Automation

214072 Revision B

4-27

Check the Refrigerant Line and Cryosurface for Leaks

About Leak Check

The leak gas used must be dry with a dew point of -80 C or less.

Helium leak checking the refrigerant line and cryosurface is an acceptable alternative to the procedure

specified below if helium leak check equipment and trained helium leak check operators are available.

If helium is used as a leak check medium, only use helium while the compressor is off and ensure that

the pressure in the line and cryosurface during this test does not exceed the lowest refrigerant pres-

Item Description

Electrical Category

Type 1 – Equipment is fully de-energized

Tool or material

Cylinder of refrigerant gas R-134a

Cylinder of dry nitrogen gas (very low dew point of -80 C) with a regulator

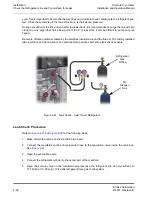

Service manifold gauge set with three hoses (manifold)

Electronic halogen leak detector with a leak sensitivity of at least 0.40 ounces

(11 g) per year

Leak detector soap

Inspection mirror

1/4 inch ratchet valve wrench

7/16 inch open-end wrench

9/16 inch open-end wrench

5/8 inch open-end wrench

15/16 inch open-end wrench

1 inch deep socket or open end or crow foot wrench

1 1/16 inch deep socket or open end wrench

1 5/16 inch deep socket or open end wrench

Adjustable wrenches as required

Reference Documents

Service Procedure, Zero Line Loss, p/n 185307

Service Procedure, Evacuation-Recovery, p/n 185308

Service Procedure, Brazing Specifications, p/n 185305

Chemical Hazard

Failure to have a qualified refrigeration technician do all refrigera-

tion work could result in system damage or personal injury.

•

Contact a qualified refrigeration technician to perform all refriger-

ant work.