Polycold Cryochiller

Installation

Installation and Operation Manual

Check the Refrigerant Line and Cryosurface for Leaks

Brooks Automation

214072 Revision B

4-29

6.

When the refrigerant line is pressurized, close the suction valve and disconnect the refrigerant cyl-

inder.

7.

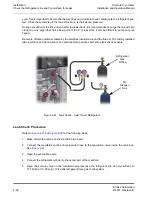

Connect the nitrogen cylinder to the center port of the manifold. See

8.

Open the suction valve and increase the pressure in the refrigerant line and cryosurface to 1030

kPa (150 psig).

9.

Close the valve on the nitrogen cylinder.

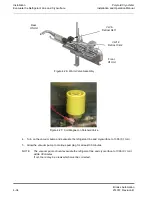

10. Use a halogen leak detector to check each connection in the refrigerant circuits. This includes the

Parker UltraSeal compatible or Cajon VCR couplings, the Evacuation Valve, and all brazed joints.

The couplings have two small access holes on each nut to help find leaks. Cover the lower access

hole with a finger and put the sensor at the higher hole. See

NOTE:

If there is a large leak and the source cannot be pinpointed without activating the leak

detector, open the manifold's suction valve until the pressure drops to about 345 kPa (50

psig). This should allow detection of the source of the leak.

NOTICE

Improper pressurization can damage refrigerant lines or system components.

Do not pressurize the refrigerant line and cryosurface above 3100 kPa (450 psig)

with the cryosurface attached to the system. The pressure relief valve may leak

if it is activated.

Figure 4-22: Leak Check - Pressurize with Nitrogen

Refrigerant

Gas

R134a

Dry

Nitrogen

Gas