Polycold Cryochiller

Installation

Installation and Operation Manual

Evacuate the Refrigerant Line and Cryosurface

Brooks Automation

214072 Revision B

4-35

6.

Close the evacuation valve while the

vacuum pump is still pumping.

Turn off the vacuum pump.

Carefully remove the hose from the

evacuation valve.

Recheck the tightness of the brass top

nut on the evacuation valve to prevent

leaking.

7.

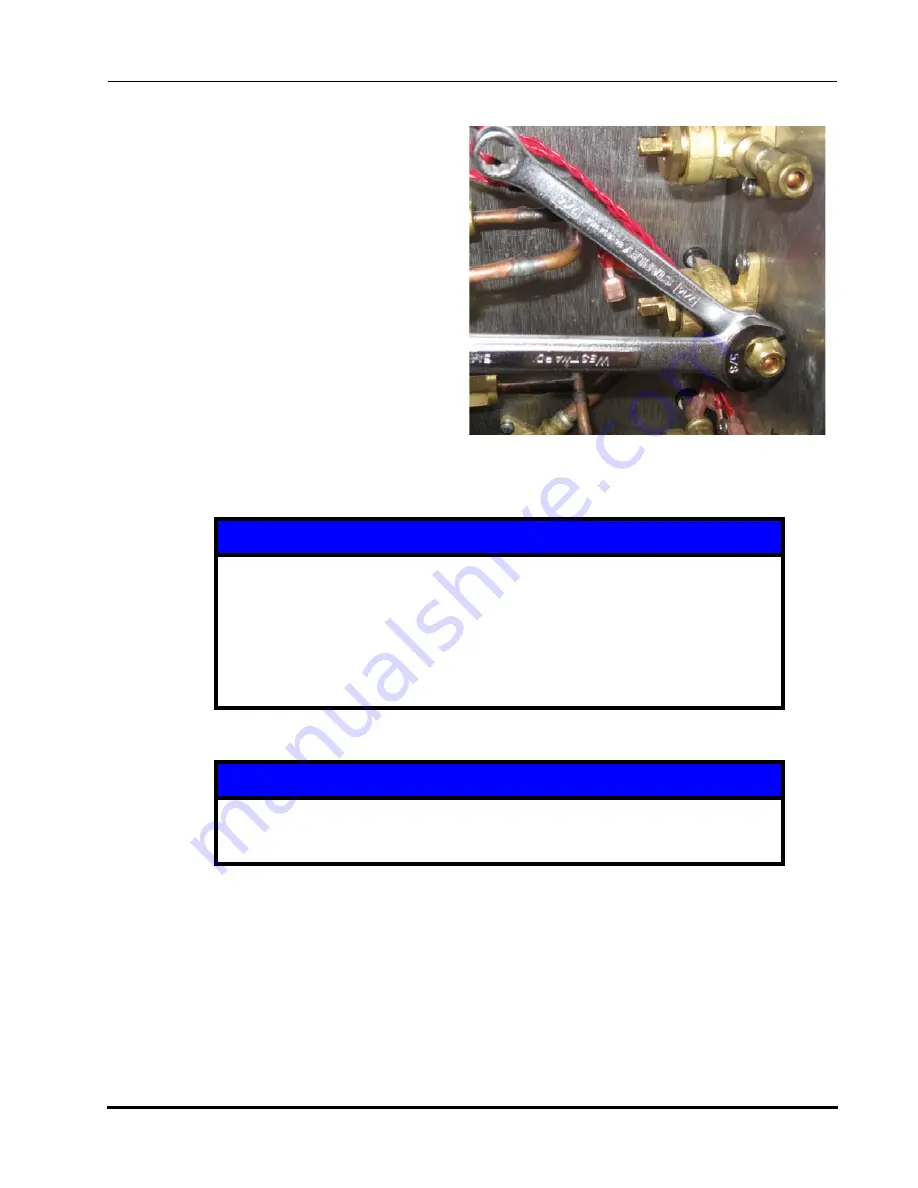

Reinstall the protective cap and flare

nut with bonnet onto the output port of

the evacuation valve. Torque to 13.6

to 20.3 Nm (10 - 15 lb-ft). See

.

8.

Remove the magnets and reinstall the

solenoid coils on the valves.

9.

Go to the Installation Checklist

.

Initial and date this task. Go to the next task.

NOTICE

Improper tightening of the refrigerant lines or caps may cause damage or leaks.

Always use correct size wrench

Always use two wrenches when connecting to or installing the refrigerant lines or

cap on the evacuation valve.

•

Use one wrench to hold the valve nut.

•

Use the other wrench to tighten the fitting or cap.

NOTICE

It is very important to re-install the protective cap and flare nut with bonnet onto

the evacuation valve to prevent refrigerant leaks.

Figure 4-28: Install Cap and Flare Nut on Evacuation

Valve