Disassembly

2 - 39

D

isassembly

D

isassembly

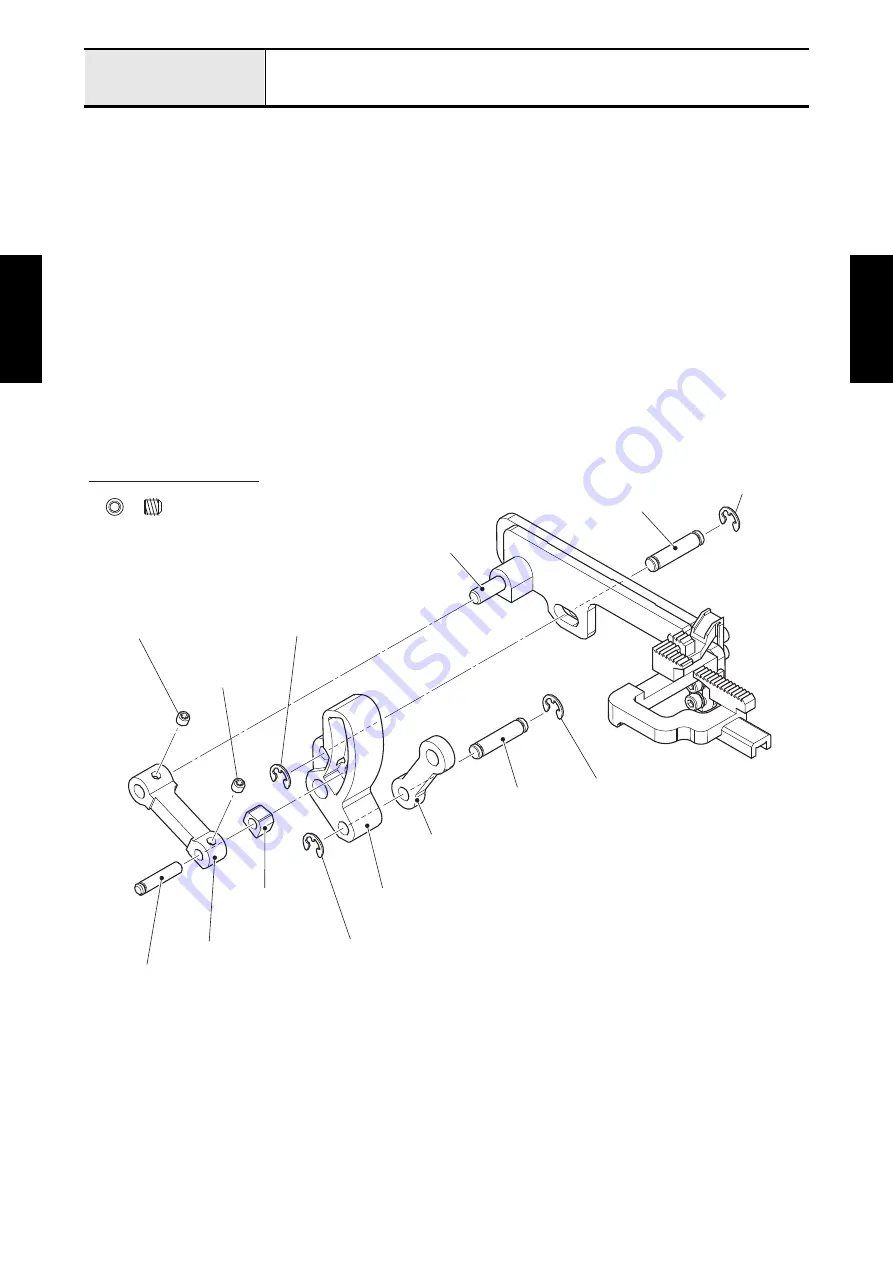

Feed mechanism

4. Remove the screw (set screw, socket (CP) M4x4) to pull out the adjusting link shaft from the differential

feed adjusting and the differential feed link.

*Assembling note

• Fully tighten the screw after performing

"Differential adjusting plate"

5. Remove the screw (set screw, socket (CP) M4x4) to remove the differential feed link from the link shaft.

6. Remove the differential feed adjusting from the feed bar lever.

7. Remove the retaining ring E4 (BK) from the feed bar lever shaft. Pull out the feed bar lever shaft to

remove the feed bar lever. Remove the retaining ring E4 from the feed bar lever shaft.

8. Remove the retaining ring E4 from the adjusting block shaft. Pull out the adjusting block shaft to

remove the feed link from the feed bar lever. Remove the retaining ring E4 from the adjusting block

shaft.

Fig. 2-4

Set Screw, Socket (CP) M4X4

Retaining ring E4 (BK)

Set screw, socket

(CP) M4x4

Set screw, socket

(CP) M4x4

Retaining ring E4

Retaining ring E4

Retaining ring E4

Adjusting link shaft

Differential feed link

Differential feed

adjusting

Feed bar lever

Feed link

Adjusting block

shaft

Link shaft

Feed bar lever shaft

Summary of Contents for 1034DX

Page 2: ......

Page 6: ...1 1 1 Main mechanisms 1 2 Driveline 1 3 Outline of Mechanism ...

Page 32: ...Disassembly 2 21 Disassembly Disassembly Presser foot unit Presser foot unit location diagram ...

Page 46: ...Disassembly 2 35 Disassembly Disassembly Feed mechanism Feed mechanism location diagram ...

Page 54: ...Disassembly 2 43 Disassembly Disassembly Driving mechanism Driving mechanism location diagram ...

Page 60: ...Disassembly 2 49 Disassembly Disassembly Needle bar Needle bar location diagram ...

Page 87: ...34KH15HF884B02 03 ...