CHANGING THE NEEDLE

30

n

Carefully pull the end of the thread that was passed

through the eye of the needle.

*

If a loop was formed in the thread passed through

the eye of the needle, carefully pull on the loop of

thread through to the back of the needle.

o

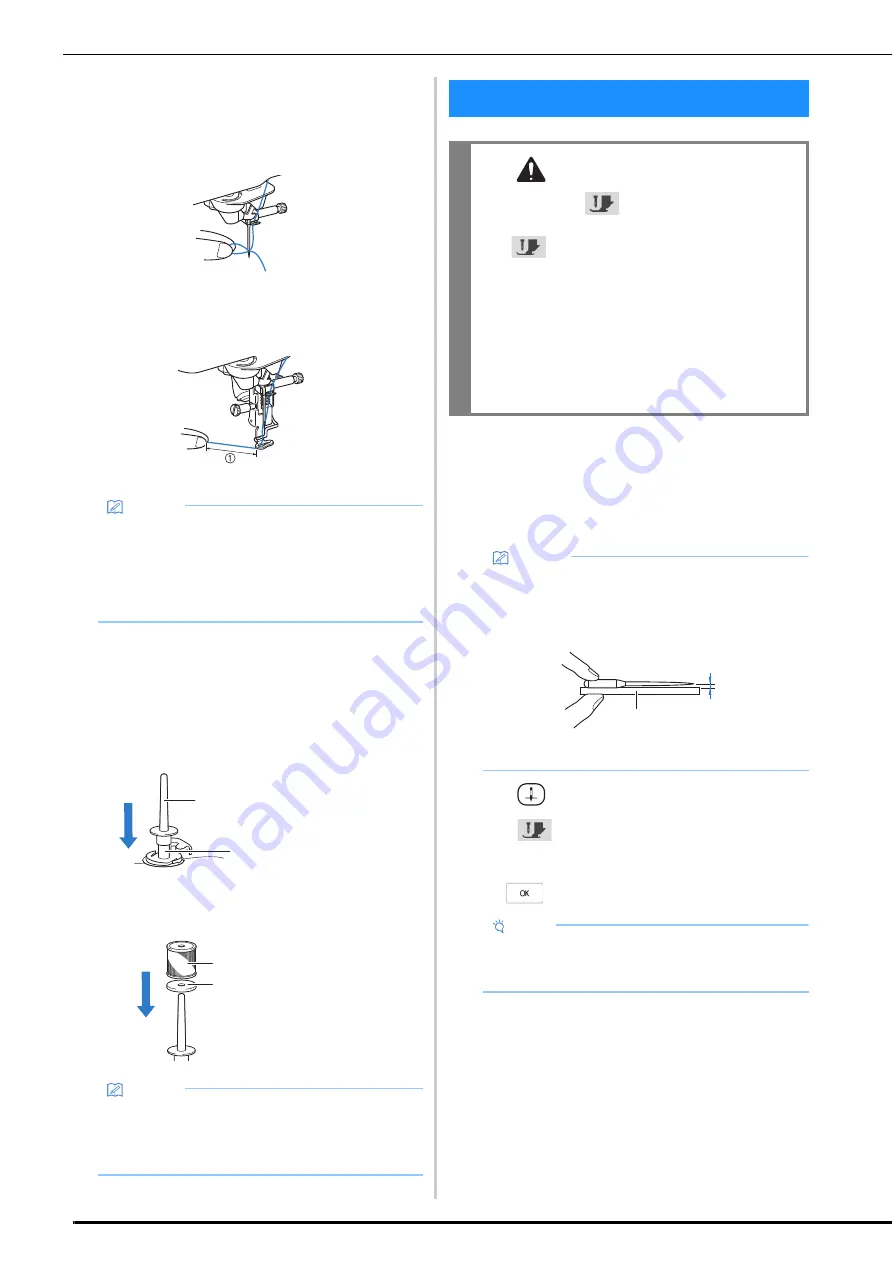

Raise the presser foot lever and pull out about 10 cm (4

inches) of the thread, and then pass it under the presser

foot toward the rear of the machine.

1

About 10 cm (4 inches)

■

Using the Vertical Spool Pin

Use the vertical spool pin when using an irregularly

shaped thread spool, and when embroidering with

metallic thread.

a

Insert the vertical spool pin onto the bobbin winder

shaft.

b

Install the spool felt and the thread spool in that order,

and then thread the upper thread.

■

Thread and Needle Number

The lower the thread number is, the heavier the thread;

the higher the needle number, the larger the needle.

■

Embroidery Needles

Use a ball point needle 75/11.

a

Press

(Needle position button) to raise the needle.

b

Press

to lock all keys and buttons.

*

If the message [OK to automatically lower the

presser foot?] appears on the LCD screen, press

to continue.

c

Remove the presser foot. (page 107)

Memo

• If the needle could not be threaded or the thread

was not passed through the needle bar thread

guides, perform the procedure again starting from

step

c

.

Then, pass the thread through the eye of the

needle after step

i

.

1

Bobbin winder shaft

2

Vertical spool pin

1

Spool felt

2

Thread spool

Memo

• When setting the thread spool, set it so that the

thread winds off from the front of the spool.

• This method keeps the thread from twisting as it

comes off the spool pin.

b

a

b

a

CHANGING THE NEEDLE

CAUTION

• Always press

on the screen to lock all

keys and buttons before changing the needle.

If

is not pressed and the “Start/Stop”

button or another operation button is pressed

accidentally, the machine will start and injury

may result.

• Use only home sewing machine needles. Other

needles may bend or break and may cause

injury.

• Never use a bent needle. A bent needle will

easily break and may cause injury.

Memo

• To check the needle correctly, place the flat side of

the needle on a flat surface. Check the needle from

the top and the sides. Throw away any bent

needles.

1

Parallel space

2

Flat surface (bobbin cover, glass, etc.)

Note

• Before replacing the needle, cover the hole in the

needle plate with fabric or paper to prevent the

needle from falling into the machine.

a

b

Summary of Contents for 882-W80

Page 2: ......

Page 10: ...CONTENTS 8 ...

Page 34: ...CHANGING THE NEEDLE 32 ...

Page 35: ...Chapter 2 Basic Embroidery ...

Page 70: ...ADJUSTMENTS DURING THE EMBROIDERY PROCESS 68 ...

Page 71: ...Chapter 3 Advanced Embroidery ...

Page 86: ...EMBROIDERY APPLICATIONS 84 ...

Page 87: ...Chapter 4 My Design Center ...

Page 106: ...STIPPLING 104 ...

Page 107: ...Chapter 5 Appendix ...

Page 123: ......