26

CHAPTER 6

TROUBLESHOOTING

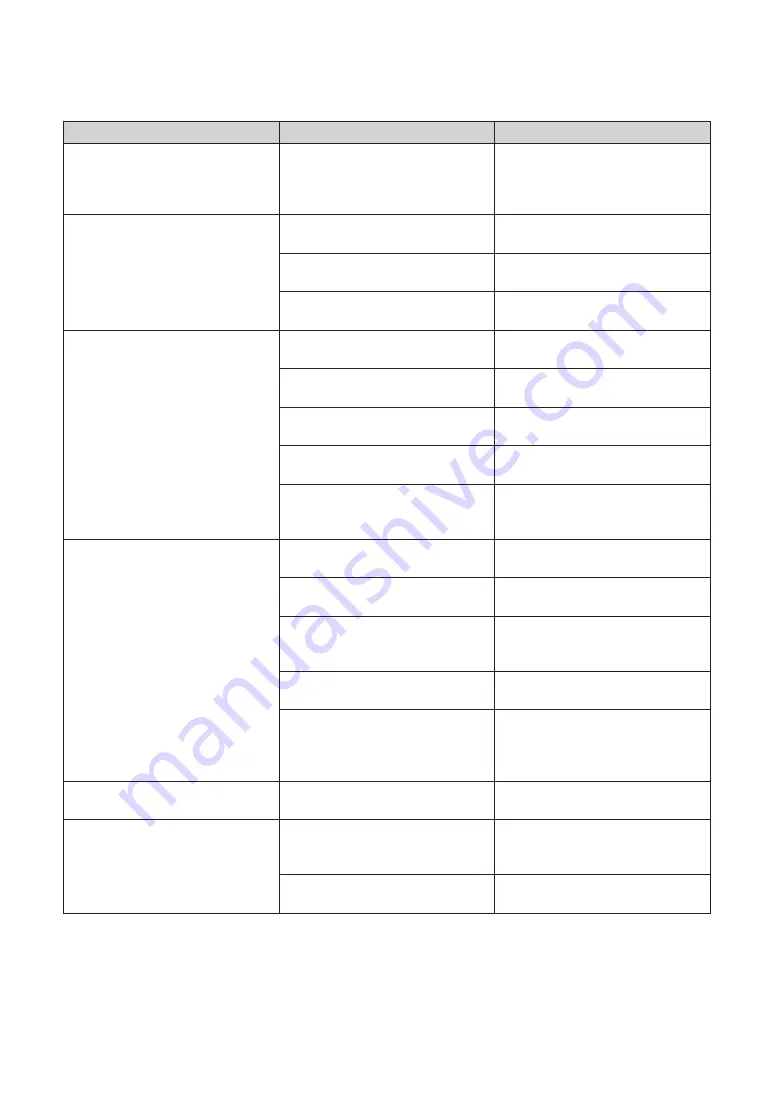

This sewing machine is designed for trouble-free operation. However, the following chart indicates trouble

which may occur if basic adjustments are not made properly.

Trouble

Cause

Remedy

1. Does not feed

Presser foot pressure too loose

Turn the pressure adjustment

screw clockwise to increase the

presser foot pressure.

(See page 9.)

2. Needles break

1. Needles bent, or needle tip blunt Replace with new needle.

(See page 13.)

2. Needles incorrectly installed

Install needles correctly.

(See page 13.)

3. Material pulled forcibly

Do not press or pull material too

hard when sewing.

3. Threads break

1. Improper threading

Thread correctly.

(See pages 15-18.)

2. Thread tangled

Check spool pin, thread holders,

etc. and remove tangled thread.

3. Thread tension too tight

Adjust the thread tension.

(See pages 10-12.)

4. Needles incorrectly installed

Install needles correctly.

(See page 13.)

5. Wrong needle used

Use correct needle.

130/705H - suggested

(See page 13.)

4. Skipped stitches

1. Needle bent, or needle tip blunt Replace with new needle.

(See page 13.)

2. Needle incorrectly installed

Install needle correctly.

(See page 13.)

3. Wrong needle used

Use correct needle.

130/705H - suggested

(See page 13.)

4. Improper threading

Thread correctly.

(See pages 15-18.)

5. Presser foot pressure too loose Turn the pressure adjustment

screw clockwise to increase the

presser foot pressure.

(See page 9.)

5. Stitches are not uniform

Thread tensions are not adjusted

properly

Adjust the thread tension.

(See pages 10-12.)

6. Fabric is puckered

1. Thread tension too tight

Decrease thread tension when

sewing lightweight or fine material.

(See pages 10-12.)

2. Improper threading or thread

tangled

Thread correctly.

(See pages 15-18.)