APPENDIX

65

4

CAUTION

• Never use bent needles. Bent needles can

easily break, possibly resulting in injuries.

Note

• After completing this procedure, continue with

the following procedure in “Checking machine

operations” to check that the machine is operating

correctly.

Memo

• Since the needle may have been damaged

when the fabric was caught in the machine, we

recommend replacing it with a new one.

■

Checking machine operations

If the needle plate has been removed, check

machine operations to confirm that installation

has been completed correctly.

1

Turn on the machine.

2

Select (middle needle position stitch).

Note

• Do not yet install the presser foot and

thread.

3

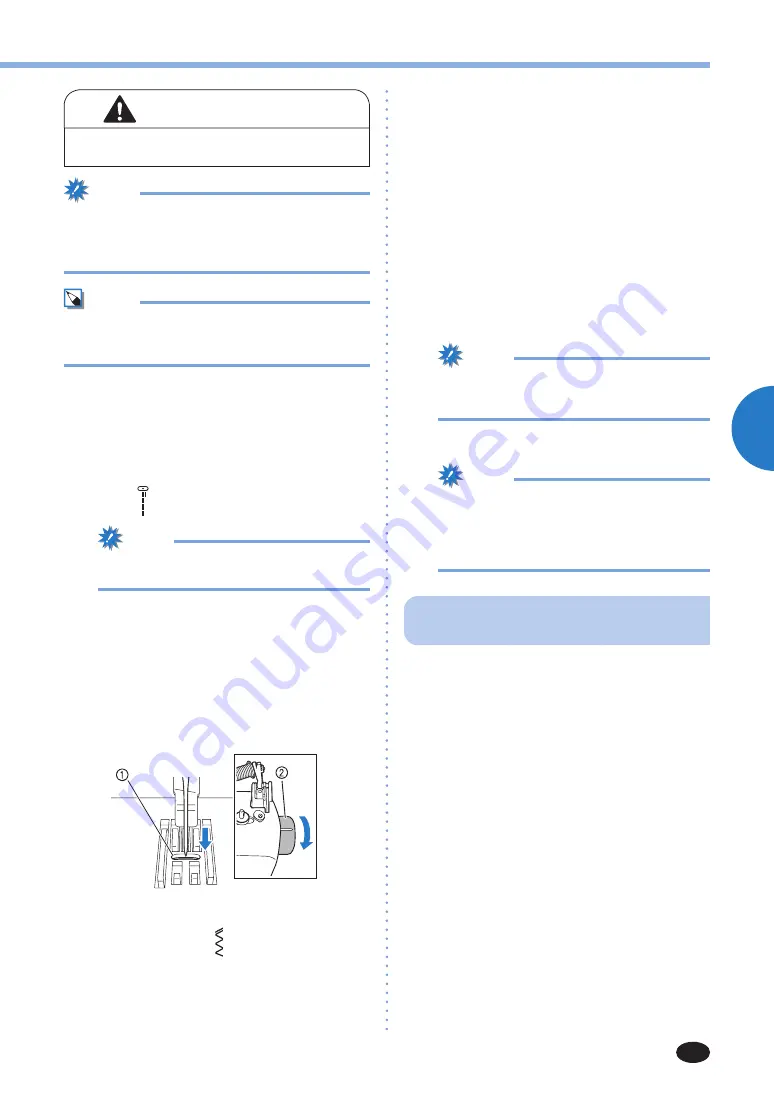

Slowly turn the handwheel toward you

(counterclockwise), and look from all sides

to check that the needle falls at the center of

the hole in the needle plate.

If the needle contacts the needle plate, remove

the needle plate, and then install it again,

starting with step

13

in “Removing the fabric

from the machine” (page 64).

1

Hole in the needle plate

2

Handwheel

4

Select zigzag stitch . At this time, increase

the stitch length and width to their maximum

settings.

• Refer to “Adjusting the stitch length and

width” (page 26).

5

Slowly turn the handwheel toward you

(counterclockwise) and check that the needle

bar and feed dogs operate correctly.

If the needle or feed dogs contact the needle

plate, the machine may be malfunctioning;

therefore, contact your nearest authorized

service center.

6

Turn off the machine, and then install the

bobbin and presser foot.

• Refer to “Lower threading” (page 14) and

“Replacing the presser foot” (page 23).

7

Correctly thread the machine.

• Refer to “Upper threading” (page 16).

Note

• The thread may have become tangled as a

result of incorrect upper threading. Make

sure that the machine is correctly threaded.

8

Perform trial sewing with normal fabric.

Note

• Incorrect sewing may be the result of

incorrect upper threading or sewing thin

fabrics. If there are poor results from the

trial sewing, check the upper threading or

the type of fabric being used.

Error message “E6” appears in

the LCD

If the error message “E6” appears in the LCD with

the occurrence of one of the following symptoms,

follow the procedure below to solve the problem.

Symptom 1 : The machine rattles and then stops

just after sewing is started.

Symptom 2 : The upper thread is tangled, for

example, in the race, or fabric is

caught in the machine.

Symptom 3 : The needle breaks, or the needle

bends and thus hits the needle

plate.

Symptom 4 : The fabric is not fed.

Symptom 1 :

The machine rattles and then stops just after

sewing is started.

■

Cause

• The upper thread is not threaded correctly.

• The thread take-up lever is not threaded.

* When the machine stops just after sewing is started,

the upper thread may not be threaded correctly.