KNOWING YOUR SEWING MACHINE

6

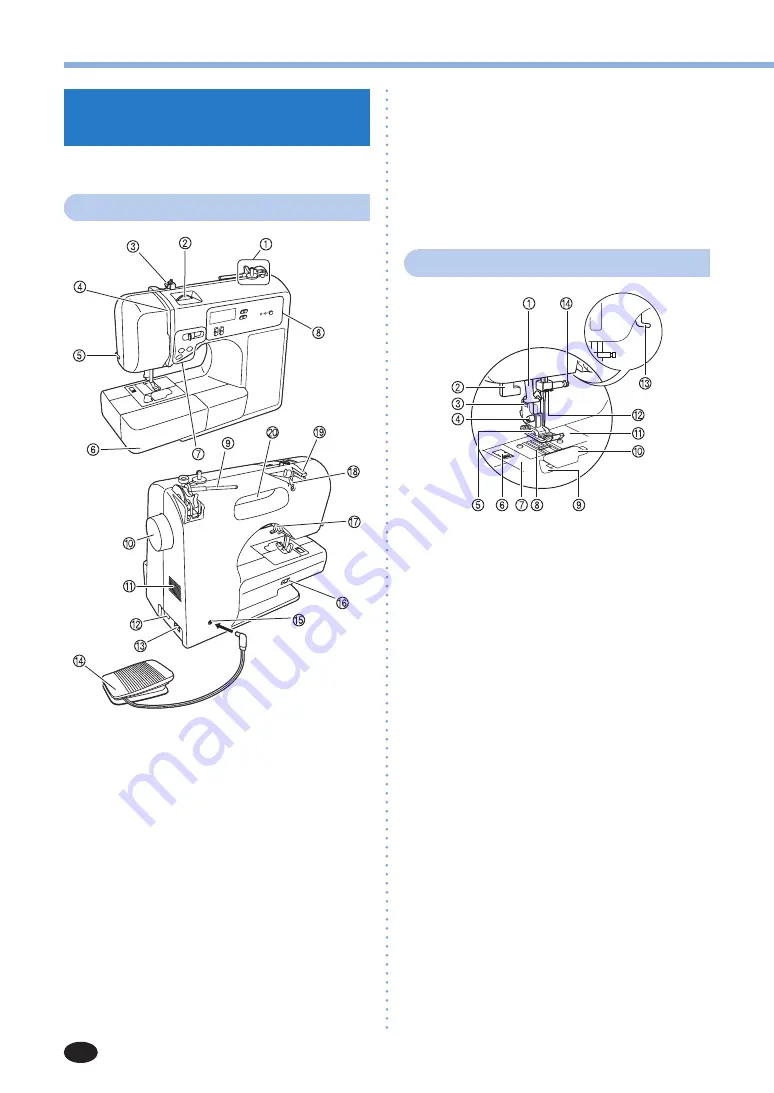

NAMES OF MACHINE PARTS

AND THEIR FUNCTIONS

The illustrations in this operation manual may differ

from the actual machine.

The main parts

1

Bobbin winder (page 11)

2

Upper tension-control dial (page 28)

3

Bobbin-winding thread guide and pre-tension disc

(page 11)

4

Thread take-up lever (page 17)

5

Thread cutter (page 27)

6

Flat bed attachment with accessory compartment

(page 5 and 31)

7

Operation buttons (page 7)

8

Operation panel (page 7)

9

Spool pin (page 8, 11 and 16)

<

Handwheel

This is used to manually raise and lower the needle.

A

Air vent

This vent allows the air surrounding the motor to

circulate. Do not cover the air vent while the sewing

machine is being used.

B

Main power and sewing light switch (page 9)

C

Jack/socket connector (page 9)

D

Foot controller (page 9)

E

Foot controller jack/socket (page 9)

F

Feed dog position lever (page 38 and 43)

G

Presser foot lever (page 16)

H

Thread guide (page 12 and 17)

I

Thread guide cover (page 17)

J

Handle

Carry the sewing machine by its handle when

transporting the machine.

Needle and presser foot section

1

Needle threader (for models equipped with the needle

threader) (page 18)

2

Buttonhole lever (page 36 and 45)

3

Presser foot holder

The presser foot is installed onto the presser foot holder.

4

Presser foot holder screw

Use the presser foot holder screw to hold the presser

foot holder in place.

5

Presser foot

The presser foot applies pressure consistently on the

fabric as the sewing takes place. Attach the appropriate

presser foot for the selected stitching.

6

Needle plate cover release

Use when removing the needle plate cover.

7

Needle plate cover

8

Feed dogs

The feed dogs feed the fabric in the sewing direction.

9

Quick-set bobbin (for models equipped with the

quickset bobbin)

You can start sewing without pulling up the bobbin

thread.

0

Bobbin cover

A

Needle plate

The needle plate is marked with guides for sewing

straight seams.

B

Needle bar thread guide (page 18)

C

Presser foot lever

Raises and lowers the presser foot.

D

Needle clamp screw