Overcasting Stitches

75

3

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

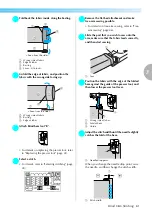

Sewing overcasting stitches using zigzag foot "J"

Seven stitches can be used to sew overcasting stitches with zigzag foot "J".

CAUTION

a

Attach zigzag foot "J".

• For details on replacing the presser foot, refer

to "Replacing the presser foot" (page 43).

b

Select a stitch.

• For details, refer to "Selecting stitching"

(page 49).

c

Sew along the edge of the fabric with the

needle dropping off the edge at the right.

a

Needle drop point

Stitch Name

Pattern

Application

Stitch Width

[mm (inch)]

Stitch Length

[mm (inch)]

Presser

Foot

Auto

Manual

Auto

Manual

Zigzag stitch

(center

needle

position)

7

Preventing fraying (center

baseline/reverse stitching)

3.5

(1/8)

0.0-7.0

(0-1/4)

1.4

(1/16)

0.0-4.0

(0-3/16)

J

Zigzag stitch

(right needle

position)

8

Preventing fraying (right

baseline/reinforcement stitching)

2.5-5.0

(3/32-3/16)

0.3-4.0

(1/64-3/16)

2-point

zigzag stitch

9

Preventing fraying in thick

fabrics and stretch fabrics

5.0

(3/16)

1.5-7.0

(1/16-1/4)

1.0

(1/16)

0.2-4.0

(1/64-3/16)

3-point

zigzag stitch

10

Overcasting

stitch

14

Preventing fraying in stretch

fabrics

0.0-7.0

(0-1/4)

2.5

(3/32)

0.5-4.0

(1/32-3/16)

15

Preventing fraying in thick

fabrics and stretch fabrics

16

Preventing fraying in stretch

fabrics

4.0

(3/16)

4.0

(3/16)

1.0-4.0

(1/16-3/16)

●

Be sure to turn off the main power before replacing the pressor foot. Otherwise, injuries may

occur if

(Start/stop button) is accidentally pressed and the machine starts sewing.

J

a

a

Summary of Contents for 885-V31

Page 2: ......

Page 16: ...14 ...

Page 70: ...SEWING BASICS 68 ...

Page 170: ......

Page 171: ......