Names of Machine Parts

10

■

Embroidery unit

1

Embroidery frame holder (page 84)

2

Frame-securing lever (page 84)

3

Embroidery unit connection (page 80)

4

Carriage (page 80)

5

Release button (page 81)

■

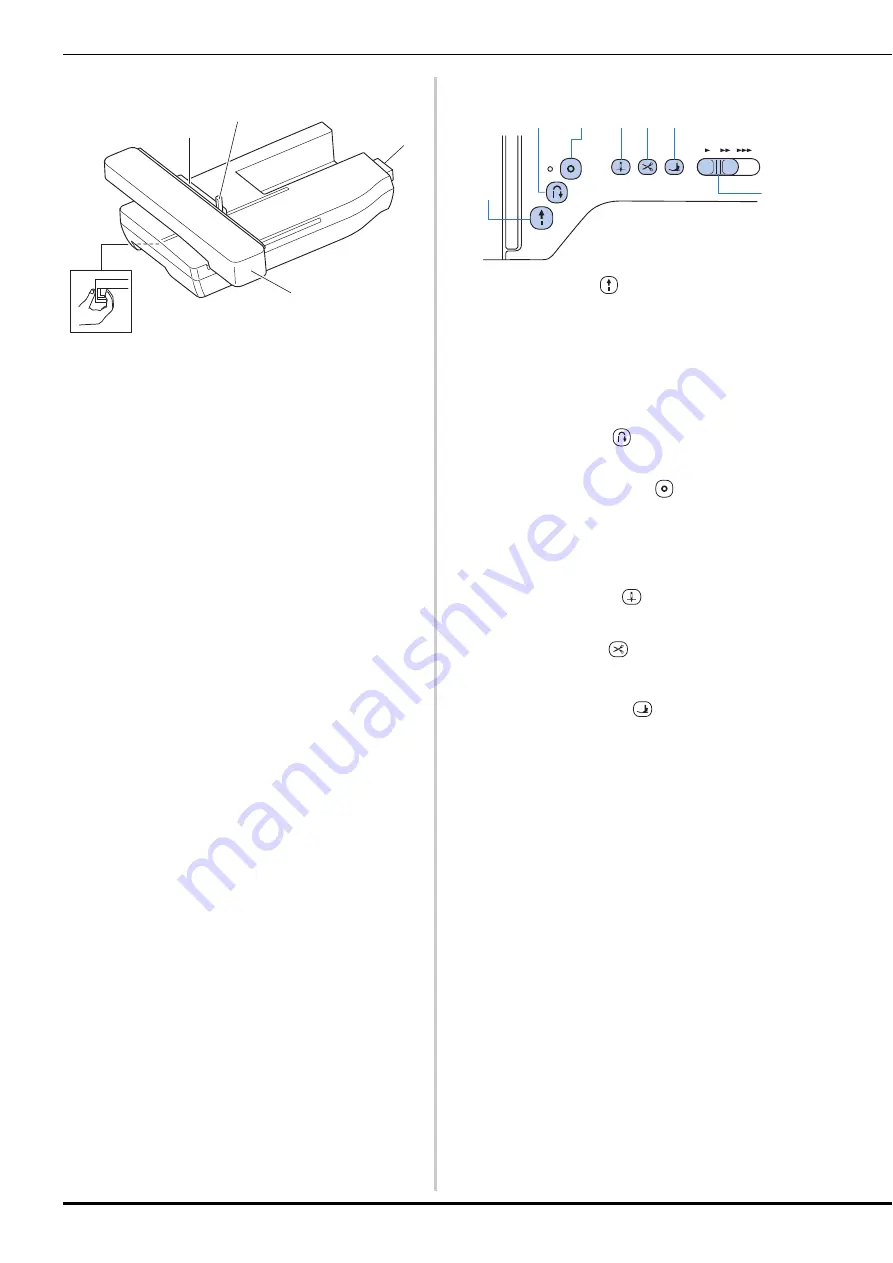

Operation buttons

1

“Start/Stop” button

Press the “Start/Stop” button to start or stop sewing.

The button changes color according to the machine’s

operation mode.

2

Reverse stitch button

Press the reverse button to sew reverse or reinforcement

stitches depending on the selected stitch pattern. (page 34)

3

Reinforcement stitch button

Press the reinforcement button to sew a single stitch

repeatedly and tie-off. (page 34)

For character/decorative stitches, press this button to end with

a full stitch instead of at a mid-point.

The LED beside the button automatically lights up while the

stitch is being sewn and goes off when sewing is finished.

4

Needle position button

Press the needle position button to raise or lower the needle.

Pressing the button twice sews one stitch.

5

Thread cutter button

Press the thread cutter button after sewing is stopped to cut

both the upper and the bobbin threads.

6

Presser foot lifter button

Press this button to lower the presser foot and apply pressure

to the fabric. Press this button again to raise the presser foot.

7

Sewing speed controller

Slide the sewing speed controller to adjust the sewing speed.

a

b

d

e

c

Green:

The machine is ready to sew or is sewing.

Red:

The machine cannot sew.

Orange:

The machine is winding the bobbin thread, or

the bobbin winder shaft is moved to the right

side.

b

c

d e f

a

g

Summary of Contents for 888-G30

Page 2: ......

Page 80: ...MY CUSTOM STITCH 78 ...

Page 121: ......

Page 122: ......

Page 123: ......