KNOWING YOUR SEWING MACHINE

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

17

d

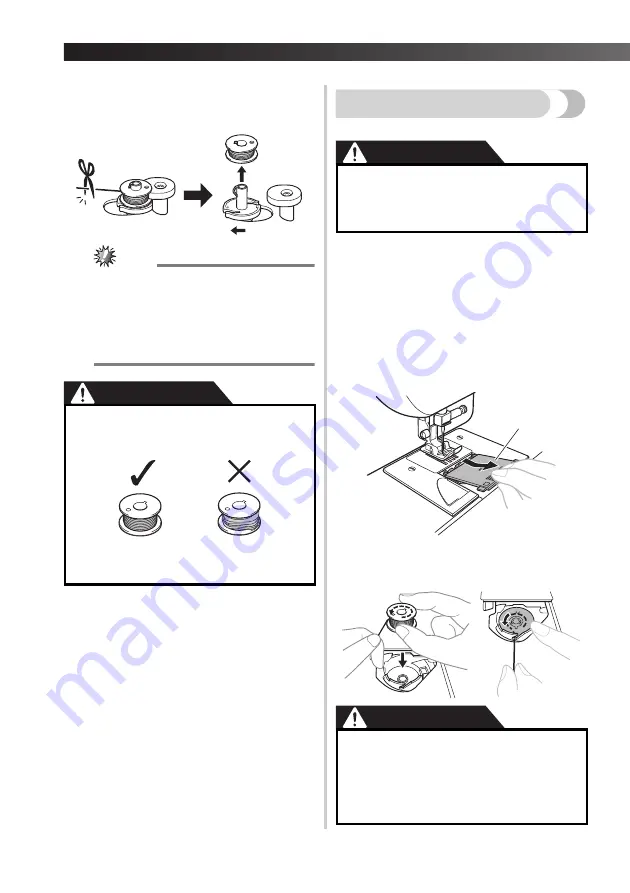

Cut the thread, slide the bobbin winder

shaft to the left, and then remove the

bobbin from the shaft.

Note

●

When the sewing machine is started or the

handwheel is turned after winding the

thread around the bobbin, the machine will

make a clicking sound; this is not a

malfunction.

●

The needle bar does not move when you

slide the bobbin winder shaft to the right.

CAUTION

Lower threading

Install the bobbin wound with thread.

CAUTION

1

Prepare the bobbin wound properly

before threading the lower thread.

• See page 14 for the details about bobbin

winding.

2

Raise the needle by turning the

handwheel toward you

(counterclockwise) and raise the presser

foot lever.

3

Remove the bobbin cover by sliding it and

lift toward you.

1

Bobbin cover

4

Put the bobbin in so the thread comes out

in the direction shown by the arrow.

CAUTION

●

Not winding the bobbin properly may

cause the thread tension to loosen, and

may break the needle.

1

Wound evenly

2

Wound poorly

1

2

●

Make sure you turn off the machine

while threading. If you accidentally step

on the foot controller and the machine

starts to sew, you could be injured.

●

Make sure you set the bobbin so the

thread unrolls in the right direction. If

the thread unrolls in the wrong

direction, it may cause the thread

tension to be incorrect or break the

needle.

1

Summary of Contents for 888-X39

Page 32: ...SEWING BASICS 31 ...

Page 82: ...FUNCIONES DE COSTURA BÁSICAS 31 ...

Page 102: ......

Page 103: ......