63

4

e

While holding the mat level and lightly

inserting it under the feed rollers on the left and

right sides of the feed slot, press

in the

operation panel.

• For details, see “Loading the Mat” on page 27.

X

The “Start/Stop” button in the operation panel

lights up.

f

Press the “Start/Stop” button to start scanning.

■

Creating Cutting Data

The procedure for creating cutting data differs

depending on the mode.

Grayscale recognition mode

a

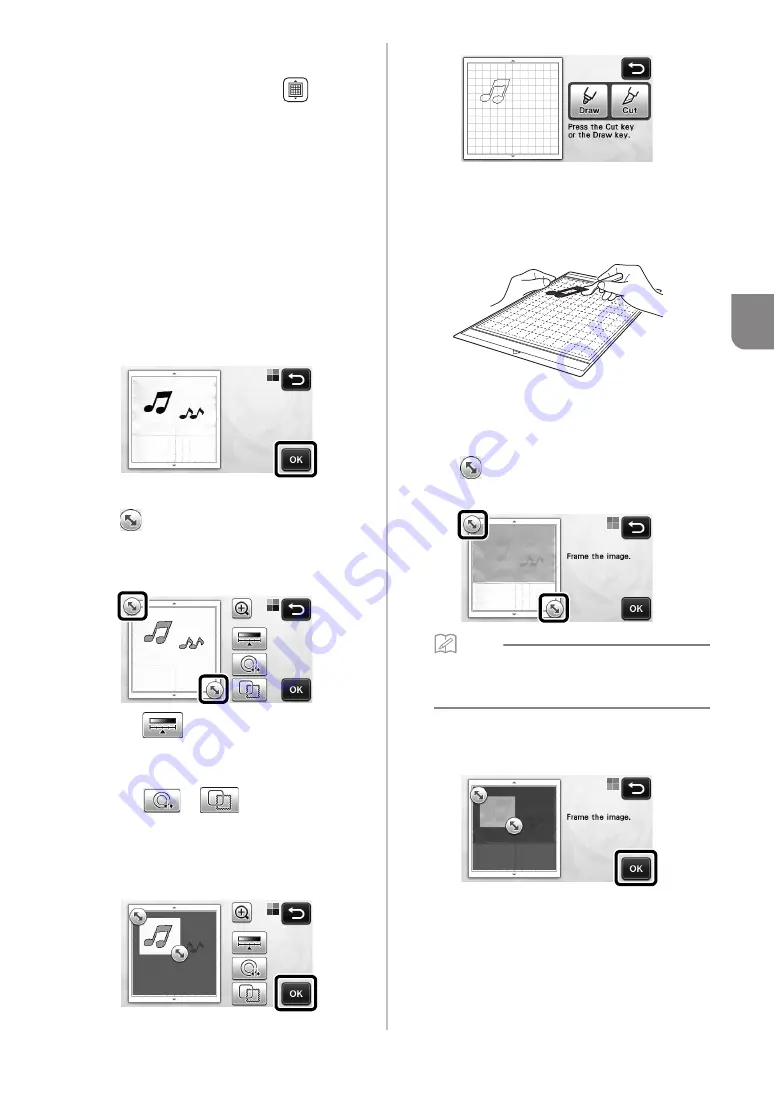

Check the scanned image, and then touch the

“OK” key.

b

In the image trim screen, use the touch pen to

drag

to trim the image to the size to be

imported.

X

If cutting lines are created, the outline of the

scanned illustration will be black.

• Touch

to change the minimum object size

that will be detected and the conversion threshold.

For details, see “Adjusting Image Detection Levels”

on page 72.

• Touch

or

to edit the imported

cutting data. For details, see “Advanced Cutting

Functions for “Direct Cut”” on page 64.

c

Touch the “OK” key to confirm the trimmed

area.

X

Only the cutting lines appear.

d

Press the “Start/Stop” button to start cutting.

• For details on unloading the mat after cutting,

follow the procedure under “Unloading the Mat”

on page 28.

Color recognition mode

a

In the image trim screen, use the touch pen to

drag

to trim the image to the size to be

imported.

Memo

• Trimming the image to the desired size can

reduce the amount of time required to convert it

to cutting data.

b

Touch the “OK” key to confirm the trimmed

area.

X

The image is converted to cutting data.