24

Adjusting the Blade Extension

The appropriate blade extension differs depending on the material type and thickness. Before installing the

holder in the carriage, turn the holder cap to adjust the blade extension, and then perform trial cutting. For

details on trial cutting, see “Trial Cutting” on page 27.

■

Cutting Settings

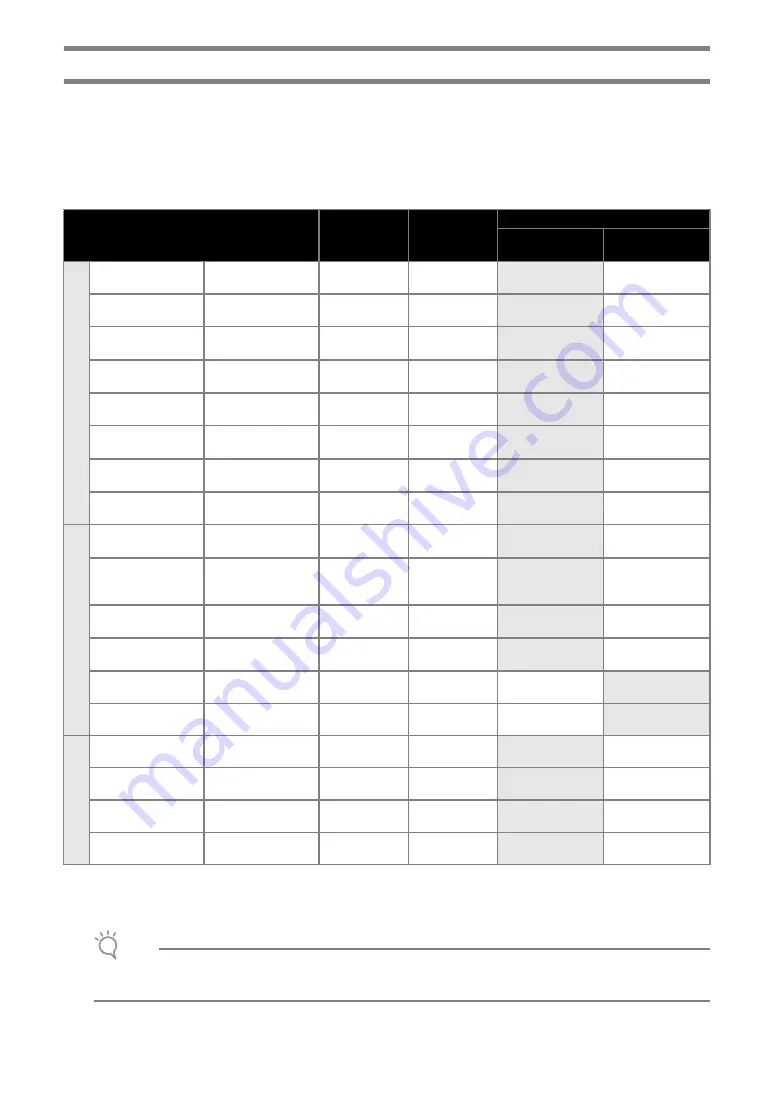

Use the following table to select the appropriate settings according to the material that will be cut.

*

Adjust the setting for “Cut Pressure” in the settings screen (page 30).

*

Use a high tack adhesive fabric support sheet or a iron-on fabric appliqué contact sheet when you cut a piece of

fabric out. For details, see “Mat and Material Combinations” on page 16.

Note

•

The settings indicated in the table are approximations. The setting will differ depending on the type and

thickness of the material to be cut. Be sure to perform a trial cutting first.

Material and its thickness

Blade scale

setting

Cut pressure

setting

Cutting blade

Standard cut blade

(turquoise)

Deep cut blade

(purple)

Pap

e

r

Printer paper

80 g/m² (0.1 mm)

3

-1

3

Scrapbook paper

(thin)

120 g/m²

(0.15 mm)

3.5

0

3

Scrapbook paper

(medium-thick)

200 g/m²

(0.25 mm)

4

0

3

Cardstock (thin)

200 g/m²

(0.25 mm)

4

0

3

Cardstock (medium-

thick)

280 g/m²

(0.35 mm)

5

0

3

Vellum, tracing

paper

0.07 mm

3

0

3

Poster board (thin)

280 g/m²

(0.35 mm)

5.5

0

3

Poster board (thick)

400 g/m²

(0.5 mm)

7.5

4

3

Fabric

Thin cotton fabric

(for quilt piece)

0.25 mm

4

4

3

Thin cotton fabric

(except for quilt

piece)

0.25 mm

4

4

3

Flannel (for quilt

piece)

0.6 mm

6.5

4

3

Flannel (except for

quilt piece)

0.6 mm

6.5

4

3

Felt

1 mm

5

5

3

Denim 14 oz

0.75 mm

5.5

6

3

Ot

he

rs

Plastic sheet (PP)

0.2 mm

4

0

3

Vinyl

0.2 mm

4

0

3

Magnet

0.3 mm

5.5

0

3

Sticker or seal

0.2 mm

4

0

3