Chapter 5 Adjustment

BAS-6150

58

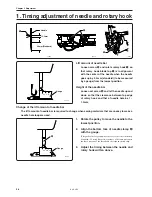

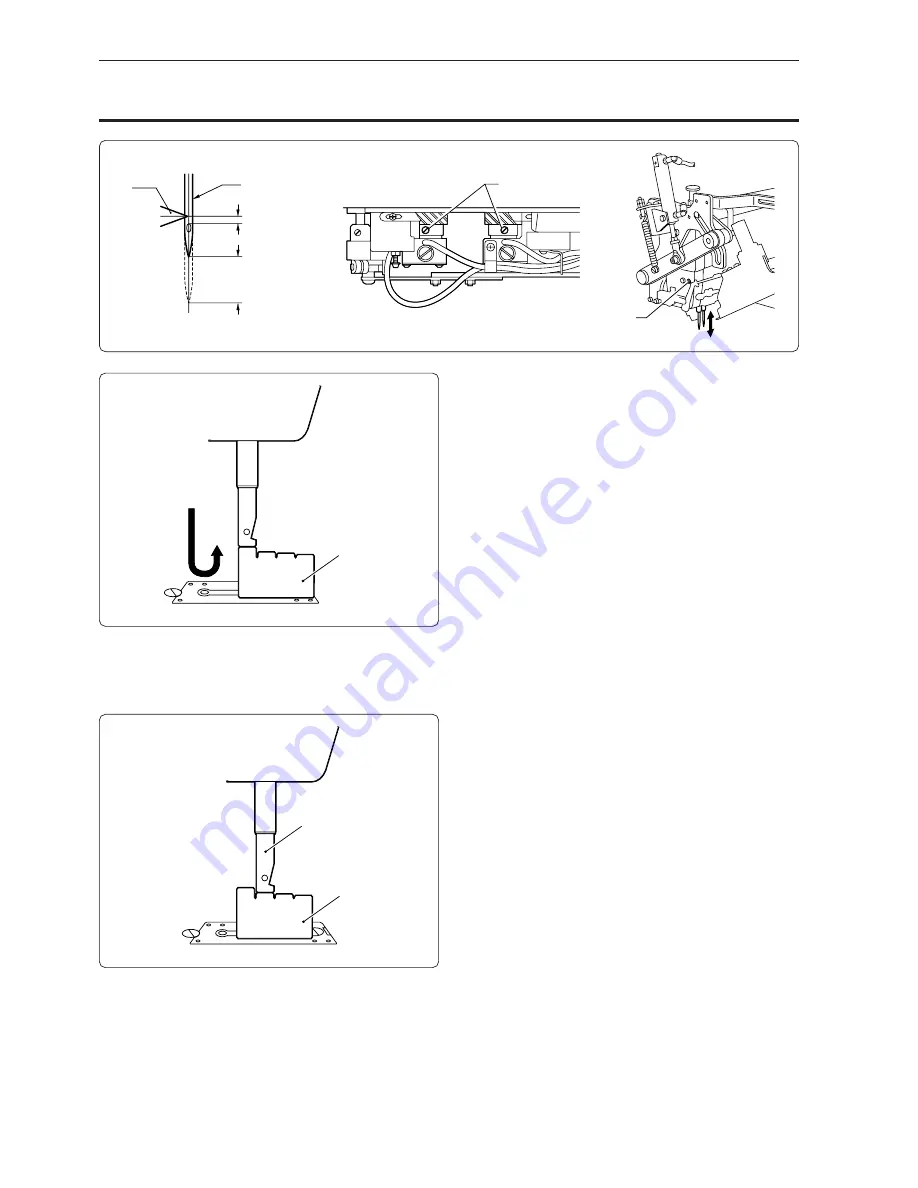

1. Timing adjustment of needle and rotary hook

Lift amount of needle bar

Loosen screw

w

and rotate rotary hook

q

so

that rotary hook blade top

q

is in alignment

with the center of the needle when the needle

goes up by 2.4 mm (standard) (to be measured

by a gauge) from the lowest position.

Height of the needle bar

Loosen set screw

e

and let the needle up and

down so that the clearance between top edge

of rotary hook and that of needle hole be 1 ~

1.5mm.

q

Needle

1-1.5mm

2.4mm(Standard)

w

e

1492S

1491S

1490S

1588S

1589S

2.4

2.8 3.5

2.4

2.8 3.5

2.4

2.8 3.5

2.4

2.8 3.5

r

Gauge

Gauge

Change of the lift amount of needle bar

The lift amount of needle bar is required to change when sewing materials that are uneasy to make a

needle hole loop are used.

1.

Rotate the pulley to move the needle to the

lowest position.

2.

Align the bottom face of needle clamp

r

with the gauge.

If aligned to the larger number, the less occurs the stitch skip.

(standard: 2.4 mm) Excessive increase of lift amount causes

the loose tension of the thread and the frequent stitch skip.

3.

Adjust the timing between the needle and

rotary hook written above.

Summary of Contents for BAS-6150

Page 2: ......

Page 11: ...Chapter 1 Machine Preparation ...

Page 29: ...Chapter 2 Sewing flow ...

Page 41: ...Chapter 3 Settings ...

Page 55: ...Chapter 4 Oiling ...

Page 59: ...Chapter 5 Adjustment For raising the head refer to 3 How to raisethehead in Chapter4 Oiling ...

Page 70: ...Chapter 5 Adjustment BAS 6150 68 ...

Page 71: ...Chapter 6 Knife replacement ...

Page 77: ...Chapter 7 Environment setting ...

Page 85: ...Chapter 7 Environment setting BAS 6150 83 Standard stacker 4 steps 0 1 3 4 2 1530S ...

Page 95: ...Chapter 8 Dipswitch ...

Page 98: ...Chapter 8 Dipswitch BAS 6150 96 ...

Page 99: ...Chapter 9 Error code List ...

Page 103: ...Chapter 10 Troubleshooting ...