Chapter 5 Adjustment

BAS-6150

59

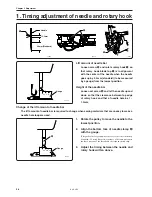

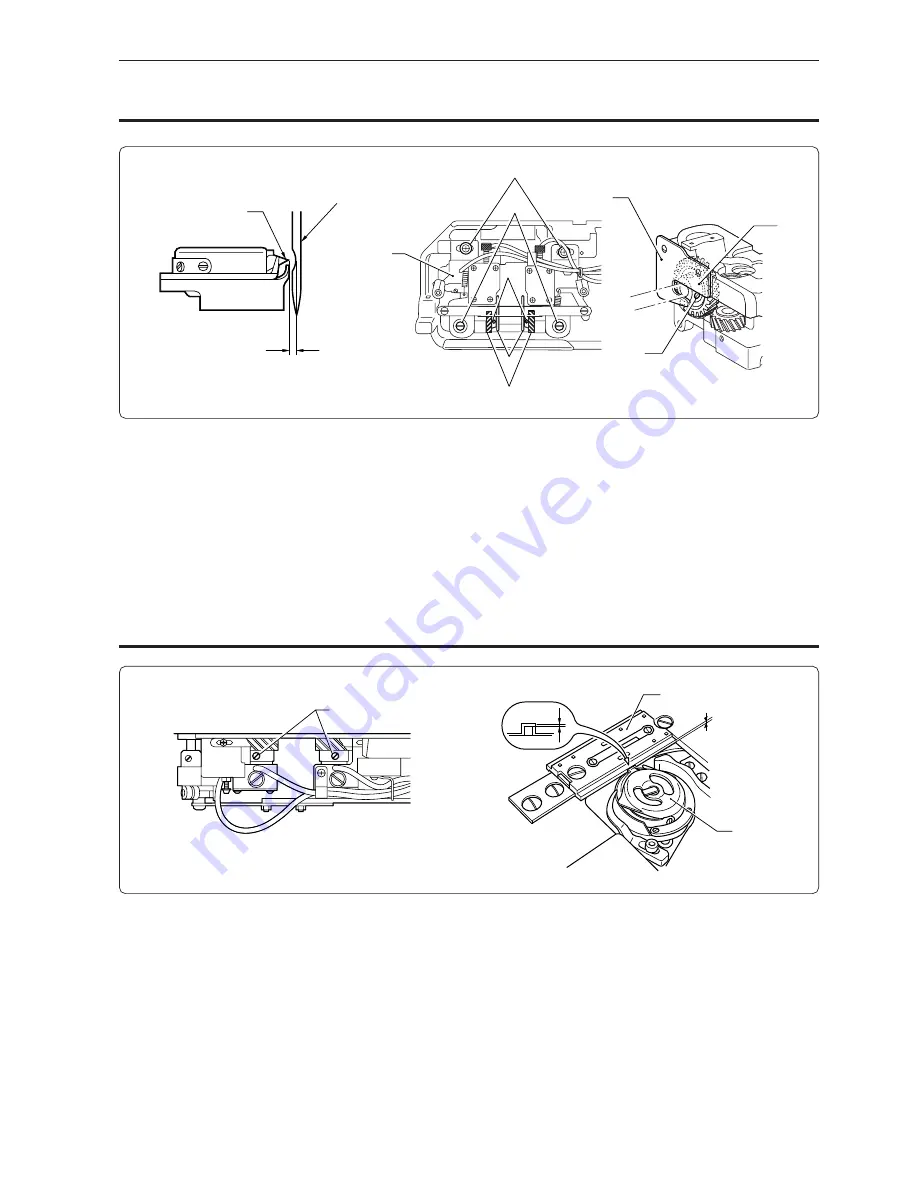

3. Clearance adjustment between rotary hook and needle plate

Loosen screw

q

and let the rotary hook

w

up and down so that the clearance between rotary

hook

w

and needle plate

e

be 0.6 - 0.9mm.

0.6~0.9mm

e

w

0.6~0.9mm

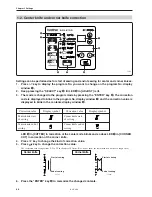

1.

Loosen screws

A

,

B

, and

C

.

2.

Let rotary hook base move

q

to left and right so that the clearance between the needle and

rotary hook blade top be 0.05mm.

3.

Fasten screws

A

,

B

, and

C

tightly after adjustment.

(Note) • Fasten set screw

C

at the position where lower shaft gear

w

touches lightly with guide plate

e

.

• Fasten set screw

C

so as not to change the tightening force of set screw

C

lower shaft gear

w

.

Rotary hook

blade top

Needle

No more than 0.05mm

q

w

e

w

A

B

C

e

C

2. Clearance adjustment between needle and rotary hook

1493S

1494S

q

1491S

1495S

Summary of Contents for BAS-6150

Page 2: ......

Page 11: ...Chapter 1 Machine Preparation ...

Page 29: ...Chapter 2 Sewing flow ...

Page 41: ...Chapter 3 Settings ...

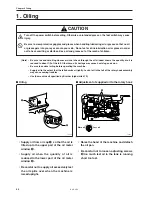

Page 55: ...Chapter 4 Oiling ...

Page 59: ...Chapter 5 Adjustment For raising the head refer to 3 How to raisethehead in Chapter4 Oiling ...

Page 70: ...Chapter 5 Adjustment BAS 6150 68 ...

Page 71: ...Chapter 6 Knife replacement ...

Page 77: ...Chapter 7 Environment setting ...

Page 85: ...Chapter 7 Environment setting BAS 6150 83 Standard stacker 4 steps 0 1 3 4 2 1530S ...

Page 95: ...Chapter 8 Dipswitch ...

Page 98: ...Chapter 8 Dipswitch BAS 6150 96 ...

Page 99: ...Chapter 9 Error code List ...

Page 103: ...Chapter 10 Troubleshooting ...