GETTING READY

————————————————————————————————————————————————————————

22

GETTING READ

Y

CONTENTS

SEWING BASICS

U

T

IL

IT

Y

S

T

ITCHES

APPENDIX

INDEX

c

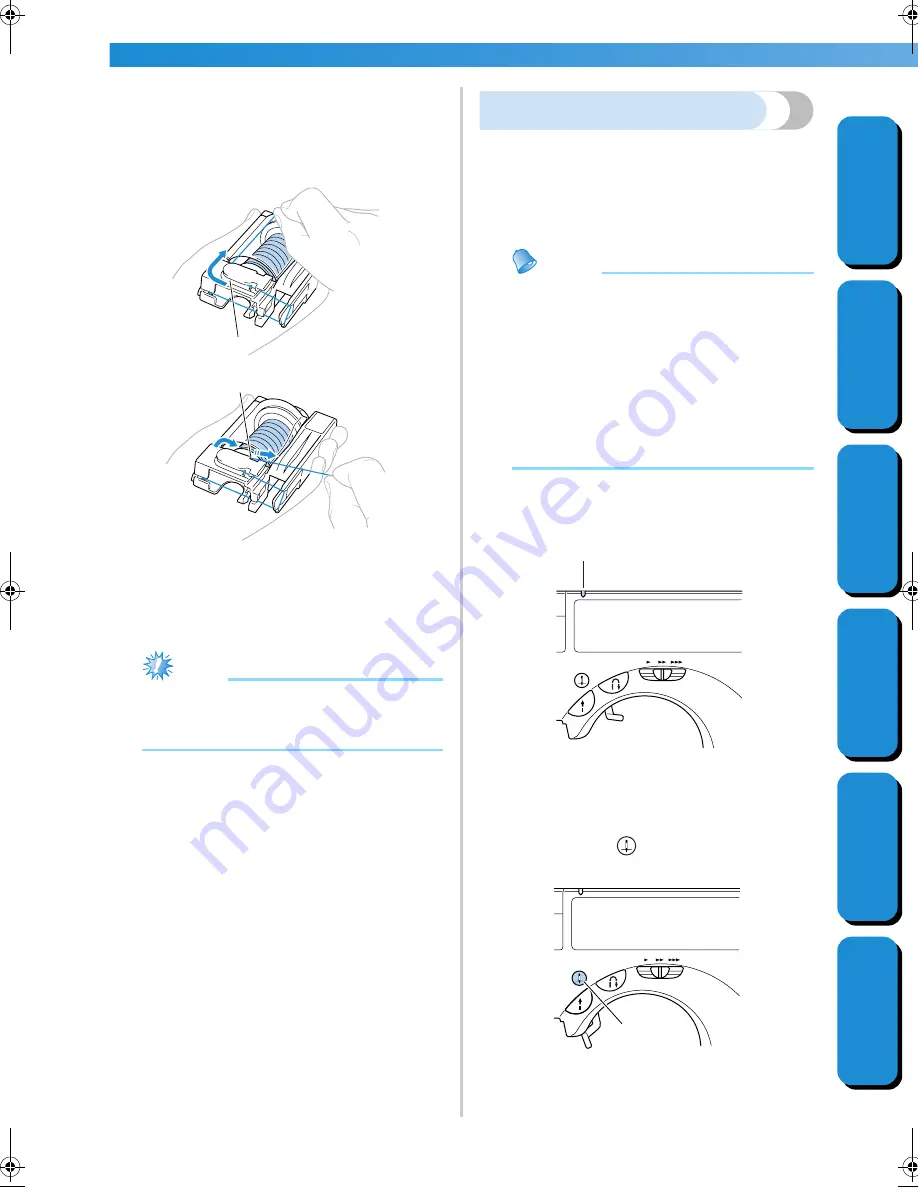

Pull the thread under the disc at the front in

the lower-left corner and around to the right,

and then cut the thread with the cutter.

Follow arrow 6 indicated on the thread

cassette.

1

Disc

2

Cutter

X

The spool of thread is now loaded in the

thread cassette.

Note

●

Be sure to cut the thread as described

above, otherwise the needle threader

cannot be used to thread the needle.

Threading the needle

In this section, the procedures for installing the

thread cassette and threading the needle are

described. The needle threader is used to thread the

needle at the same time that the thread cassette is

inserted.

Memo

●

The needle threader can be used with

sewing machine needles 75/11 through

100/16.

●

Thread with a thickness of 130/20 or less

cannot be used with the needle threader.

●

The needle threader cannot be used with

the wing needle or the twin needle.

●

If the needle threader cannot be used, refer

to “Threading the needle manually”

(page 25).

1

Check that the thread cassette indicator is lit

up in green.

1

Thread cassette indicator

If the thread cassette indicator is lit up in red,

the needle has not been raised to the correct

position. Press

(needle position button)

once to raise the needle.

1

Needle position button

1

2

1

1

S2_brotherE.book Page 22 Wednesday, May 14, 2003 8:05 PM