6

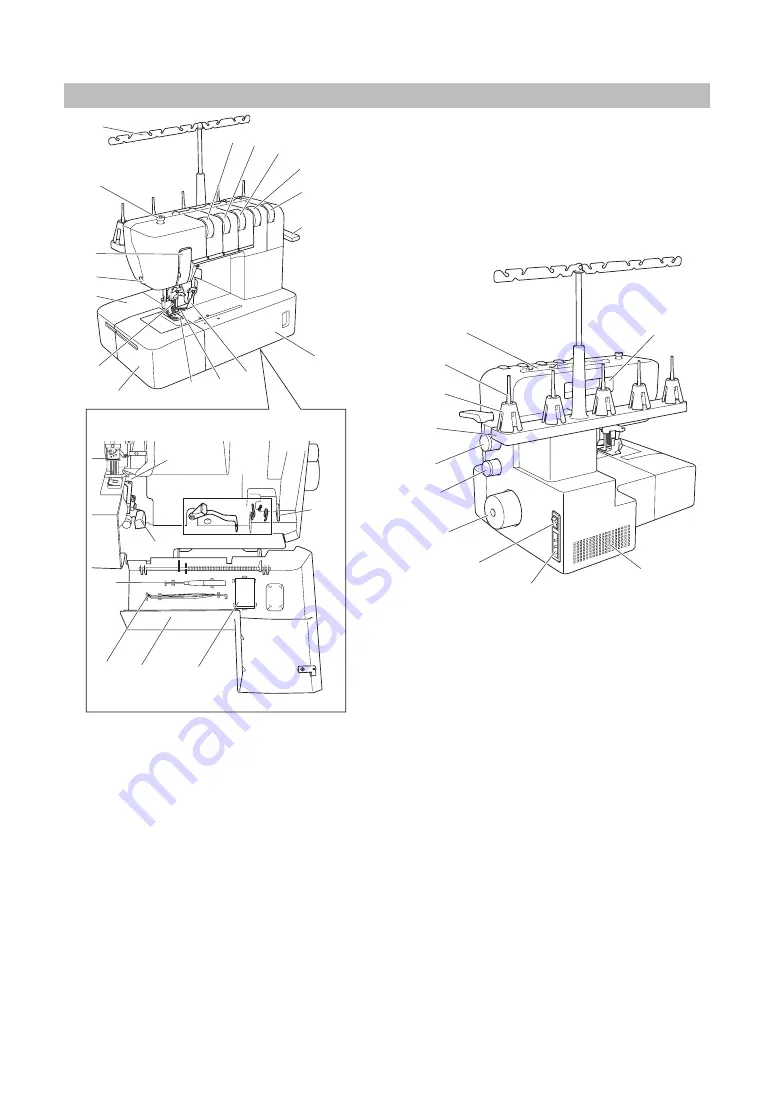

Machine (Top cover stitch model) (Product code: 884-B31)

1

Thread tree

2

Presser foot pressure adjustment screw

3

Thread take-up cover

4

Thread cutter

5

Material plate cover

6

Needles

7

Bed extension

8

Presser foot

9

Top cover spreader

0

Top cover thread guide

A

Left needle thread tension dial

B

Center needle thread tension dial

C

Right needle thread tension dial

D

Top cover thread tension dial

E

Looper thread tension dial

F

Presser foot lever

G

Front cover

H

Thread guide

I

Spool pin

J

Spool cushion

K

Spool support

L

Stitch length adjustment dial

M

Differential feed ratio adjustment dial

N

Handwheel

O

Main power and light switch

P

Foot controller socket

Q

Handle

R

Air openings

Inside of the front cover

S

Looper thread tension adjustment lever

t

Looper thread take-up

U

Looper

V

Looper release lever

W

Front cover compartment

You can store the included accessories in this

front cover compartment. <A>: Needle set, <B>:

Tweezers, <C>: Hexagonal driver

a

b

c

d

e

f

g

h

i

j

q

p

o

n

m

l

k

T

U

S

V

W

$!

%!

&!

H

L

M

N

O

P

Q

R

I

J

K

Inside of the front cover