5-81

Confidential

9.8.23

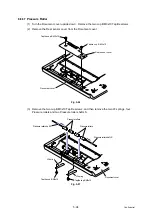

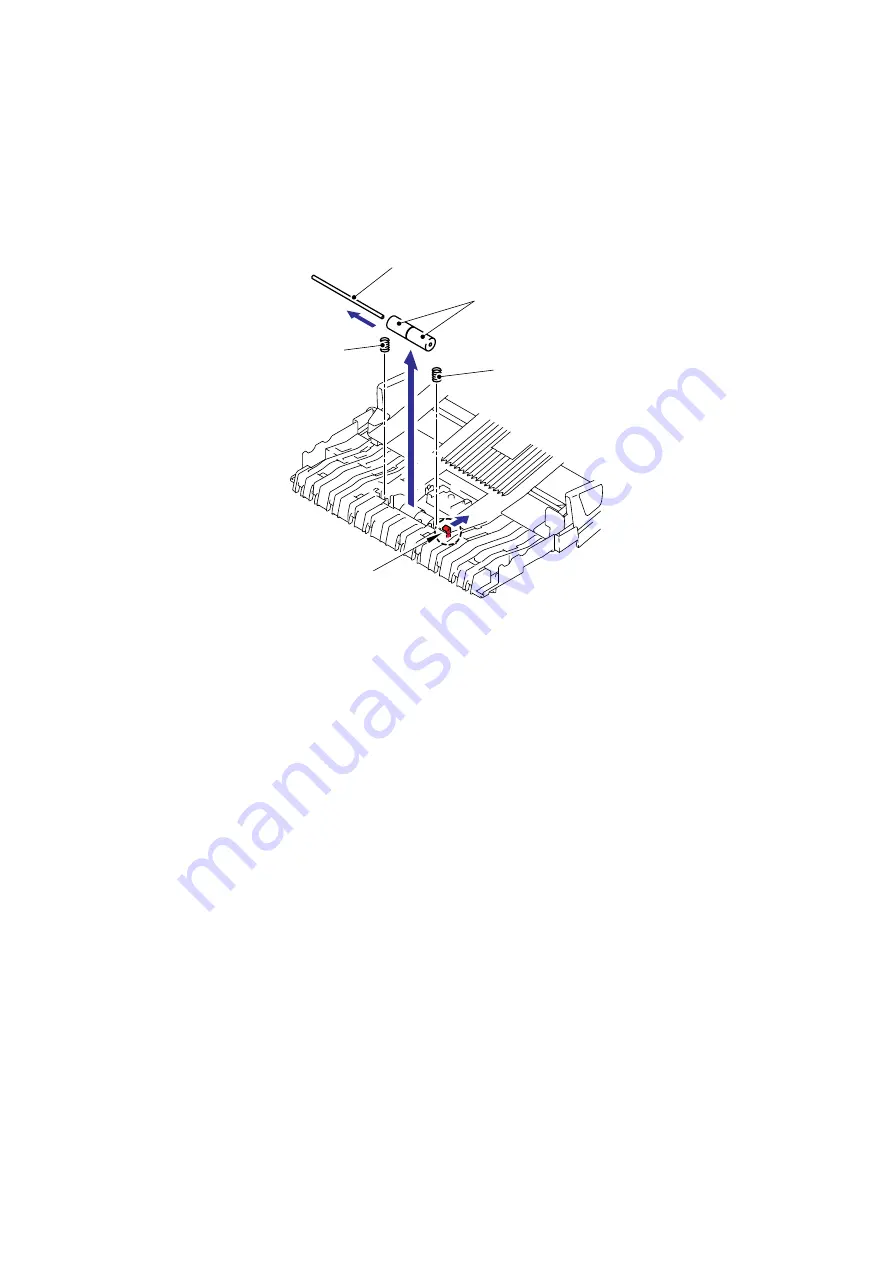

Pressure Roller / LF Spring

(1) Push the Hook to the direction of the arrow (1a) as shown in the figure below while

holding the Pressure roller, and remove the Pressure roller shaft from the hook.

(2) Pull the Pressure roller shaft out of the Pressure roller.

(3) Remove the two LF springs.

Fig. 5-73

Pressure roller shaft

Pressure rollers

LF spring

LF spring

Hook

2

1a

1b

Summary of Contents for DCP 8085DN

Page 13: ...CHAPTER 1 SPECIFICATIONS ...

Page 52: ...Confidential CHAPTER 2 THEORY OF OPERATION ...

Page 69: ...2 16 Confidential 3 3 Paper Feeding Fig 2 18 LT path DX path MP path Paper tray path ...

Page 89: ...CHAPTER 3 ERROR INDICATION AND TROUBLESHOOTING ...

Page 178: ...Confidential CHAPTER 4 PERIODICAL MAINTENANCE ...

Page 248: ...CHAPTER 5 DISASSEMBLY REASSEMBLY ...

Page 265: ...5 12 Confidential Fig 5 7 EM2 4 places Separation pad ASSY ...

Page 501: ...Confidential CHAPTER 6 ADJUSTMENTS AND UPDATING OF SETTINGS REQUIRED AFTER PARTS REPLACEMENT ...

Page 507: ...6 5 Confidential 8 Alert warning message of WHQL appears Click Continue Anyway to proceed ...

Page 516: ...CHAPTER 7 SERVICE MODE ...

Page 525: ...7 7 Confidential For color scanning Fig 7 2 ...

Page 527: ...7 9 Confidential For white and black scanning Fig 7 3 ...

Page 528: ...7 10 Confidential For color scanning Fig 7 4 ...

Page 567: ...Confidential CHAPTER 8 CIRCUIT DIAGRAMS WIRING DIAGRAM ...

Page 569: ...8 1 Confidential 1 CIRCUIT DIAGRAMS High voltage Power Supply PCB Circuit Diagram Fig 8 1 ...

Page 570: ...8 2 Confidential LVPS PCB Circuit Diagram 230V Fig 8 2 ...

Page 571: ...8 3 Confidential LVPS PCB Circuit Diagram 115V Fig 8 3 ...