3-88

Confidential

7.

TROUBLESHOOTING OF THE

COMMUNICATIONS ERRORS

If a communications error occurs, the machine

(1) Gives the alarm (intermittent bleep) for approximately four seconds.

(2) Indicates the appropriate error message on the LCD.

(3) Prints the transmission report during fax transmission.

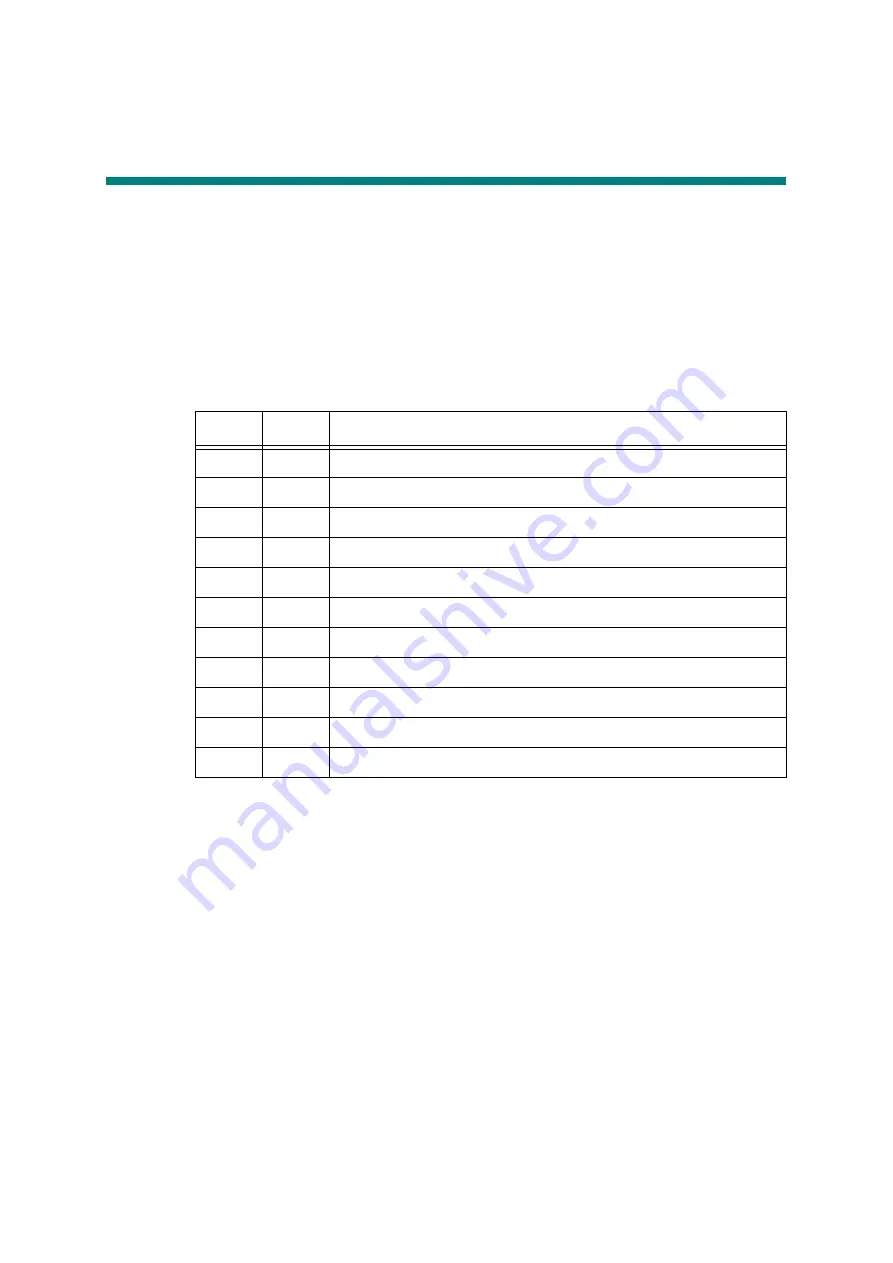

7.1 Definition of Error Codes on the Communications List

(1) Calling

*Available in German models only.

Code 1

Code 2

Cause

10

08

Wrong number called.

11

01

No dial tone detected before start of dialing.

11

02

Busy tone detected before dialing.

11

03

2nd dial tone not detected.

11

05

No loop current detected. *

11

06

Busy tone detected after dialing or called.

11

07

No response from the remote station in sending.

11

10

Unobtainable tone detected after dialing.

17

07

No response from the calling station in receiving.

Summary of Contents for DCP-9010CN

Page 11: ...Confidential CHAPTER 1 SPECIFICATIONS ...

Page 53: ...Confidential CHAPTER 2 THEORY OF OPERATION ...

Page 90: ...Confidential CHAPTER 3 ERROR INDICATION AND TROUBLESHOOTING ...

Page 201: ...Confidential CHAPTER 4 PERIODICAL MAINTENANCE ...

Page 224: ...Confidential CHAPTER 5 DISASSEMBLY AND ASSEMBLY ...

Page 440: ...Confidential CHAPTER 6 ADJUSTMENTS AND UPDATING OF SETTINGS REQUIRED AFTER PARTS REPLACEMENT ...

Page 446: ...6 5 Confidential 10 Alert warning message appears click Continue Anyway to proceed ...

Page 456: ...Confidential CHAPTER 7 SERVICE FUNCTIONS ...

Page 464: ...7 6 Confidential For color scanning Fig 7 2 ...

Page 487: ...7 29 Confidential Cover page sample Fig 7 13 End page sample Fig 7 14 ...

Page 492: ...7 34 Confidential Color registration adjustment chart Fig 7 16 ...

Page 496: ...7 38 Confidential LED test pattern M68_L Fig 7 18 ...

Page 498: ...7 40 Confidential Fig 7 19 ...

Page 500: ...7 42 Confidential Color test pattern Fig 7 20 MCYK Y C K M YCMK_ _A ...

Page 518: ...Confidential CHAPTER 8 CIRCUIT DIAGRAMS WIRING DIAGRAM ...

Page 521: ...Confidential 8 2 High voltage Power Supply PCB Circuit Diagram SYS HITEK SPH 8N35 2 3 ...

Page 522: ...Confidential 8 3 High voltage Power Supply PCB Circuit Diagram SYS HITEK SPH 8N35 3 3 ...

Page 523: ...Confidential 8 4 High voltage Power Supply PCB Circuit Diagram MURATA MPH3316 1 3 ...

Page 524: ...Confidential 8 5 High voltage Power Supply PCB Circuit Diagram MURATA MPH3316 2 3 ...

Page 525: ...Confidential 8 6 High voltage Power Supply PCB Circuit Diagram MURATA MPH3316 3 3 ...

Page 526: ...Confidential 8 7 Low voltage Power Supply PCB Circuit Diagram 100V ...

Page 527: ...Confidential 8 8 Low voltage Power Supply PCB Circuit Diagram 200V ...

Page 528: ...Confidential 8 9 NCU PCB Circuit Diagram USA Canada ...

Page 529: ...Confidential 8 10 NCU PCB Circuit Diagram Europe Asia Oceania China ...

Page 530: ...Confidential 8 11 NCU PCB Circuit Diagram South Africa Gulf ...

Page 531: ...Confidential 8 12 2 WIRING DIAGRAM Wiring Diagram 1 2 ...

Page 532: ...Confidential 8 13 Wiring Diagram 2 2 ...

Page 590: ...Confidential APPENDIX 3 SERIAL NUMBERING SYSTEM ...

Page 592: ...App 3 2 Confidential Serial number of the LED ASSY Print position Fig App 3 4 Serial number ...

Page 593: ...Confidential APPENDIX 4 SCREW CATALOGUE ...

Page 595: ...Confidential APPENDIX 5 REFERENCES ...

Page 597: ...Confidential APPENDIX 6 GLOSSARY ...